Promotional Features

Creating ingredients solutions through microencapsulation technology

Microencapsulation is a widely used and very effective way to improve the performance of ingredients in food products. Globally many manufacturers use it in their formulations to solve problems and produce better results in their end products. But what is microencapsulation and how can it help you?

What is microencapsulation?

“Microencapsulation (as it applies to the food industry) is the process whereby various food ingredients can be stored within a microscopic size shell or coating for protection and/or later release. More specifically, microencapsulation is the process of enclosing small particles, a liquid, or a gas within a layer of coating or within a matrix.”

(Sobel et al, 2014, Microencapsulation in the Food Industry)

In real terms it is a process that turns a liquid into a powder with the aim of providing certain benefits, such as making an oil soluble ingredient water soluble or increasing an active ingredient’s stability. It has uses that are far reaching across many industries and applications including pharmaceuticals, adhesives, pesticides, thermochromic dyes and food.

Over the latter half of the 20th century microencapsulation technology was used in food manufacturing to solve the issues that arose around the mass production of food.As the global population ballooned food manufacturing developed to cope with the demand. This mass production lead to issues and opportunities. For example, some of the earliest commercially available examples of encapsulating liquid ingredients to make a powder were in powdered drinks and custards.

As the technology developed it was applied to solving manufacturing issues and today microencapsulation has applications across the food industry from bakery to chewing gum and beyond.

How can microencapsulation help you?

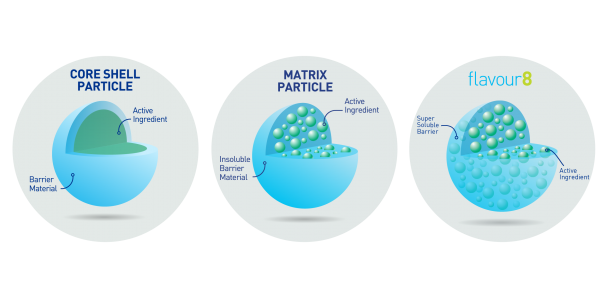

TasteTech offers three different powder encapsulation technologies that provide different benefits for different application across the food industry. Below are details on TasteTech’s encapsulation technologies and how they can be used.

Matrix Particle

Matrix Particle encapsulation wraps up a number of separate particles in an insoluble lipid barrier protecting key ingredients and allowing multiple ingredients to be encapsulated together.

The key characteristics of this process include:

● Controlled release of active ingredients

● More than one active ingredient within one particle

● Distributes evenly in application recipes

● Typical particles are uniform spheres between 150 and 275 microns

● Resists the most strenuous mixing, including high-shear mixers

● Protects of active ingredients in the end recipe allowing you to use alternative ingredients

● Superior protection from high levels of water content

The process creates dust free powders that are simple to process, easy to dose and cost-effective to use. Encapsulation can also increase the longevity of ingredients and flavourings or achieve taste masking. It enables a controlled release of the active ingredient by heat or by shear and can achieve freeze or thaw stability of sensitive ingredients.

In chewing gum, encapsulation allows the sweetener, acid and flavouring particles to withstand the gum manufacturing process and release through the shearing effect of chewing. Each chew releases a new burst of sweetness, acidity and flavour allowing chewing gum manufacturers to create innovative, high-quality, premium grade products that last longer.

In bread sorbic acid is often used as a powerful mould inhibitor, however, it reacts negatively with yeast, deactivating the yeast before it can do its job. Matrix encapsulated SorbicPlus wraps the sorbic acid in fat to stop it from reacting with the yeast. Then, when the bread is baked, it melts the fat and the acid can get to work, providing extended shelf life of up to 30 days.

These are just two examples of the many possible benefits that manufacturers can achieve when using matrix particle technology.

For more on Matrix Particle Encapsulation visit the TasteTech website.

CoreShell Encapsulation

CoreShell is TasteTech’s second main process, which wraps up a single particle in a lipid barrier, protecting them with other ingredients in a recipe.

The key characteristics of this process include:

● Controls release of active ingredient

● Reduces the rate of reaction between incompatible ingredients

● Superior protection against moisture keeping the active ingredient dry and crystalline

● Each particle is granular and typically between 500 and 1800 microns

● Maintains product quality throughout the shelf-life

● Can achieve freeze or thaw stability of sensitive ingredients

Common uses for CoreShell include protecting sugar from inverting on doughnuts and protecting salt granules in the recipes to give the effect of pockets of salt. When used as an acid coating on candy, CoreShell Acids reduces hygroscopicity without reducing the impact. The acid is encapsulated with a high loading (95%) which gives a sour impact whilst still reducing hygroscopicity protecting the acid from manufacturing to the store shelves.

For more on CoreShell encapsulation visit the TasteTech website.

flavour8

flavour8 is TasteTech’s latest encapsulation development designed to create powder flavourings for low water activity systems such as chocolate, toffee or biscuit creams. Each particle is loaded with flavour and trapped inside a super soluble barrier material. The benefits of this system include instant flavour release, over two years extended shelf life and low odour or flavour cross contamination in the finished product.

The key characteristics of this process include:

● Low odour

● Super soluble in water

● Less contamination

● High volatile retention

● Long shelf-life

● Good stability

● Each particle is typically 50 microns

flavour8 is a high load flavour system that contains 50% of the flavour material, providing high impact flavourings and potential cost in use savings. Not only that but from testing carried out by TasteTech flavour8 is up to three times more shelf stable than the equivalent un-encapsulated oil.

In chocolate, the encapsulation layer locks up the flavour to the extent that every segment of a bar can have a different flavour, without the flavours leaching.

For more on flavour8 encapsulation visit the TasteTech website.

Find out more

These are just a few examples of the way that microencapsulation can help you. Each application presents unique issues for manufacturers, some of which can be solved by using encapsulated ingredients. TasteTech has an in-house team of application food technologists that are experts in microencapsulation. They are on hand to work with R&D departments to solve problems and improve finished products.

For more on TasteTech visit our website