A new report from food consultancy Campden BRI called ‘Maximising Shelf Life’ shares valuable insights on how the combination of packaging and processes need to be optimised to reduce waste and increase shelf life, while maintaining consumer confidence without compromising product safety or quality.

Research suggests food wastage is a bigger problem than previously thought, which if cut in half would help remove around one-quarter of total greenhouse gas emissions from the global food system.

Studies by climate-action NGO WRAP from the last decade suggest that around 50% of consumer food waste can be prevented simply by extending the shelf life of products. The World Health Organization puts this into context: global reversal of food waste could save enough spoiled food to feed two billion people worldwide.

Microbial profiling, super-chilling, heat pasteurisation and modified atmosphere packaging are just of a few of the preservation techniques that food and beverage processors can adopt. Yet, with so many different quality, waste, sensory, taste and production factors to consider, uncovering the best and most sustainable option to extend the shelf life of individual fresh, frozen, ambient and bottled brands can feel like an endurance test in itself.

Given the volume of interconnecting factors, Campden BRI’s report explains step-by-step the approach food and beverage processors need to consider for any shelf-life extension project. This includes how its scientific processing and packaging experts can assist with uncovering, validating, reviewing, proving and implementing a shelf-life strategy aligned to individual product applications that meet HACCP and country-specific food safety legislation.

The need to look beyond the 'smoke and mirrors of sustainable packaging’

But there are risks and unintended consequences which also need to be carefully weighed up – for instance, for FMCG brands switching to more sustainable packaging, composite materials or plant-based formulations to minimise environmental impact.

Despite every best ethical intention, processors need to look beyond the smoke and mirrors of ‘sustainable packaging’, the report warned. For instance, if the packaging material allows gases, moisture, light and microbial contaminants in, then it inevitably shortens shelf life, leads to higher food waste and the squandering of valuable resources. Consequently, resulting in a far bigger carbon footprint.

Although packaging suppliers typically perform their own tests, the responsibility rests with manufacturers to ensure that each packaging substrate is the right one for the food and beverage type, storage conditions and protects against contamination.

Many tests determine whether packaging is fit for purpose. Campden BRI advocates testing packaging over every product’s shelf life. The rational, explained Campden BRI’s microbiological expert, Linda Everis, is threefold. To mitigate the transfer of constituents; to ensure pack and seal integrity is maintained and testing barrier properties from microorganisms. “Given the number of new materials entering the market, many with little historical data, testing the material in conjunction with the product to ensure they are both compatible over the product’s shelf-life is vital.”

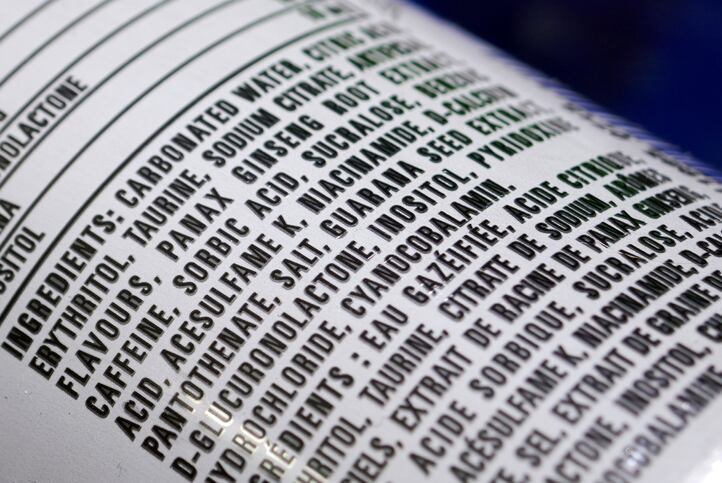

This has implications for food manufacturers attempting to balance shelf-life versus clean label. “Extending the shelf life of a food or drink product can be tricky as many preservatives and additives have unfamiliar names which can put people off buying the products," Jo Baker Perrett, Food & Drink Microstructure Team Lead at Campden BRI, explained to FoodNavigtor.

“Understanding your shelf life limiting factor is key to determining how you might get around this. If it is microbial growth that you need to limit, you may be able to reduce pH and/or add in a pasteurisation step. If it a quality issue, you can reassess your packaging, use enzymes or use a natural antioxidant such as extract of rosemary. So there are sometimes other options to having to move away from a clean label, if you want a longer shelf life.”

The options that can keep labels short and lengthen shelf life

The message for food manufacturers is to explore different ingredients, processes and packaging options that can keep labels short and also allow manufacturers to significantly affect the achievable shelf-life of a final product.

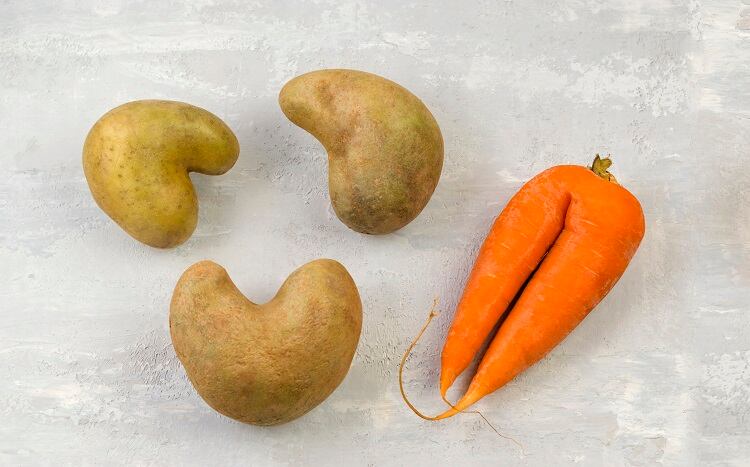

Coleslaw, for example, contains just three recognisable raw ingredients: onion, carrot and cabbage. But these raw ingredients contain potentially high microbial levels that could increase over time during storage.

Microbiologists at Campden BRI designed a study to investigate the impact of the age of these ingredients on the achievable shelf-life of coleslaw. The shelf-life end point was based on microbial levels reached within the product, the unacceptable limit of which was defined using levels stated in guidelines published in November 2009 by the then Health Protection Agency regarding assessing the microbiological safety of ready-to-eat foods.

Coleslaw made with two-day-old ingredients reached an unacceptable level of microorganisms (and therefore the end of its shelf-life) in just nine days. Whereas coleslaw made using one-day-old ingredients reached the same level after 10 days, and that made with fresh ingredients lasted 12 days. Though a UK source was used to define the microbial limit here, the overarching principal and its relationship to shelf-life is universal; whatever limit is set, it may be reached more quickly if the ingredients used contain a higher number of certain microorganisms.

This work provided invaluable insight that could be used when carefully balancing the management of ingredient waste and finished product safety and quality.

Other methods – such as 'superchilling' – allow for a longer shelf life without adding to the ingredient list. Superchilling is the point at which a product starts to freeze, and facilitates a long shelf-life without affecting the product’s sensory attributes. The reduced temperature drastically slows the rate at which microbial and chemical spoilage defects develop.

In collaboration with Campden, Lyons Seafoods adopted the superchilling technique and was able to extend the shelf-life of their cooked prawn products. What’s more, the project brought a 20% decrease in water and electricity use and meant that Lyons were able to cook bigger batches less often (which reduced their product waste and hygiene costs).

Similarly, Innocent Drinks partnered with Campden BRI to employ high pressure processing (HPP) to destroy the types of microorganisms that can limit the shelf-life of this type of product.

Manufacturers can also explore predictive modelling to best maintain the balance between shelf-life and clean labels. Predictive modelling is the computer simulation of the growth of microorganisms in food and beverage products and is by far the quickest method to assess levels of microbial growth, allowing cost effective exploration of different ‘what if’ scenarios when developing new products, reformulating or extending shelf-life.