‘There are so many different potential applications’: Indoor farming specialist pioneers ultrasonic technology to grow plants with sound

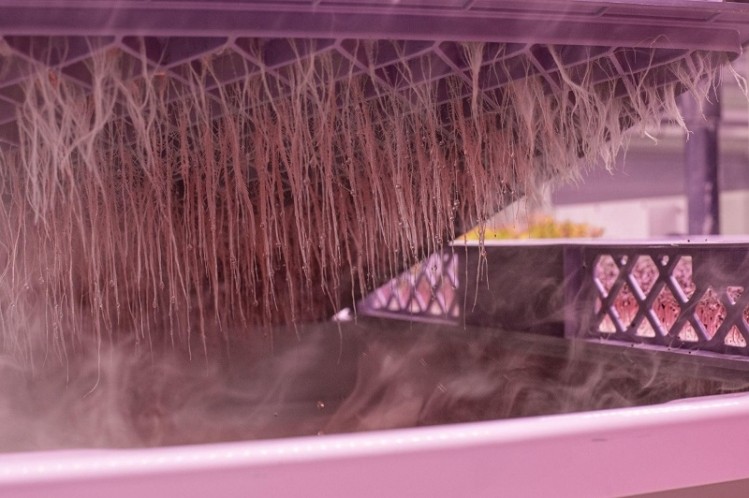

The Bristol-based company supplies vertical farm technology to farms and growers in the UK. Its customers use the equipment to cultivate leafy greens and herbs. Founded in 2015, LettUS Grow secured 2.9 million dollars in seed funding at the beginning of 2020. It specializes in aeroponics: a method of growing plants without soil. Instead of growing in soil, plant roots are suspended in air -- this mimics the air pockets found in a healthy soil system, boosts access to oxygen, and results in much faster growth of the plant.

The company says its patent-pending technology has huge potential in the UK but there are even more opportunities abroad, especially in places such as Scandinavia, where there’s very little natural light in winter, or the Middle East, where water is at a premium.

Growing plants with sound

The company has now revealed it is experimenting with applying ultrasonic technology to grow crops inside vertical farms and greenhouses.

It claims this innovation has the potential to increase domestic food production and conserve natural resources.

Ultrasonics is sound that travels at frequencies above 20,000 Hz - above the range of human hearing. It’s commonly used in sonar or imaging, but its application in large-scale, commercial horticulture is completely novel, according to the start-up. This alternative growing method, it said, allows plant roots to grow healthier and faster than in hydroponics, which is the most common irrigation system used in greenhouses and vertical farms today. In-house trials at LettUs Grow have shown that this ultrasonic method can grow some crops up to twice as fast as in comparable hydroponic systems, while also using much less water.

By using ultrasonics and enabling growers to grow more crops per year using less resources, this innovation could be key to meeting the growing demand for nutritious food in the UK without sacrificing sustainability, said the company’s co-founder & CEO of LettUs Grow Charlie Guy.

“Events in recent months and years have shone a spotlight on the scale of the problems posed by our current globalised food system. Now more than ever, it’s vital that we have the technology and infrastructure in place to support sustainable, domestic food production. Being able to grow more food, closer to where it’s eaten, whilst also using less resources, can have a massive impact on food security and our Net Zero ambitions.

“By harnessing our unique ultrasonic technology, we can offer growers the ability to grow consistent, healthy & high-quality produce with far less impact on our natural environment.”

Smoke on the water

To grow plants with sound, ultrasonic technology is harnessed to create high-frequency sound waves that shake water, until it disperses into lots of tiny droplets, like a mist. This mist, explained Guy, can be distributed and controlled to provide the exact amount of water and nutrients to plant roots depending on their needs and stage of growth.

Irrigating plants with mist rather than liquid water is not new. But Professor Antony Dodd, a Research Group Leader at the John Innes Center, said the technology offers a unique way to improve food growing efficiency.

“Controlled environment agriculture represents an important part of the sustainable production of safe and nutritious food. Whilst many people are familiar with hydroponic cultivation, aeroponic systems such as the technology developed by LettUs Grow present opportunities to increase the efficiency of food production and diversify the range of crops grown under these conditions.”

The type of aeroponics typically employed at vertical farms use nozzles to generate mist. However, technical complexities and issues with maintenance have prevented aeroponics being successful in larger scale agricultural applications such as greenhouses, according to LettUsGrow.

Nozzle-free

A key component of ultrasonic aeroponics is the use of an atomiser, the device which transforms liquid into mist, it said. This removes the need for nozzles, therefore increasing the viability of using aeroponics in much larger, commercial growing spaces, where its impact is maximized.

“If you can increase the speed of growth even by 1 or 2% on a large scale, you can have a huge impact on your ability to grow nutritious food that is so greatly needed, in a far more sustainable way - and we’re seeing increases of up to double,” said Lilly Manzoni, Head of Research & Development at LettUs Grow. “This is also the first atomiser that has been specifically designed for aeroponic agriculture. This means we’ve developed them to be durable and operationally efficient, with the environment and the grower in mind.”

‘An array’ of potential applications

As well as being designed to benefit commercial agriculture, aeroponics is also ideal for research applications, the company claims. This is because the nature of the mist, rather than water, and access to the roots, means it’s possible to have a very precise high-level of control over plants in the system.

“What’s really exciting is that we’re really at the very beginning of exploring how aeroponics can be used to create the ideal environment for life. Since it’s possible to tune the frequencies and wave profiles, we can potentially create different droplet sizes and match these to different phases or types of growth, or design different atomisers for different root types,” says Tom Didiot-Cook, Electrical Engineer in the R&D team at LettUs Grow.

"This means that there are so many different potential applications of harnessing this technology, such as in forestry, biomass production and other projects that could improve & protect natural ecosystems."