Plant-based steak alternatives are considered something of a ‘holy grail’ in the meat-free world, where mimicking the fibrous texture synonymous with whole cuts presents a significant challenge.

Some players turn to scaffolding in laboratories to achieve a steak-like texture, while others leverage 3D printing technology.

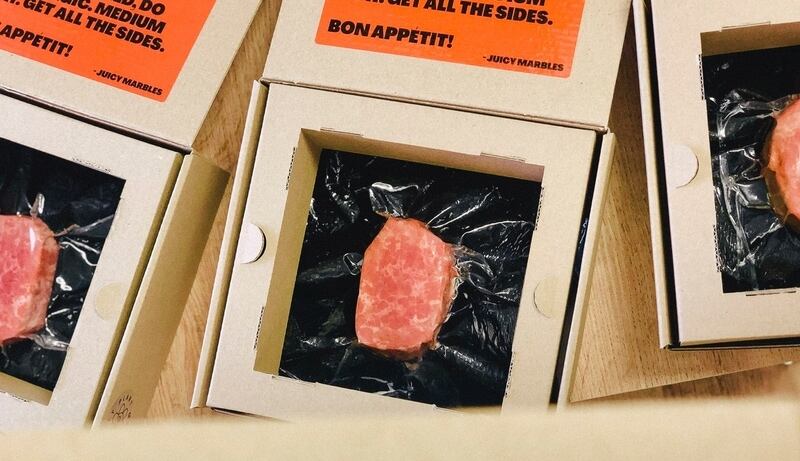

Slovenian start-up Juicy Marbles is taking a different approach again. Its patent-pending machine, known as the Meat-o-Matic Reverse Grinder 9000, enables the start-up to mimic the muscle texture and marbling of meat by aligning and layers fibres from the bottom up.

The result is a ‘world first’ in plant-based meat analogues, according to co-founders, who revealed its marbling is made from a store-cupboard ingredient: sunflower oil.

Looking beyond vegan burgers

Juicy Marbles was founded last year by food technologist Tilen Travnik, microbiologist Luka Sincek, and biotechnologist Maj Hrovat.

“Our food system’s current mode of operations cause environmental problems, health problems, and is failing its basic task of feeding humans properly. Not only from a nutritional aspect, but also in terms of distribution” said Hrovat.

“There are more than 780 million hungry people and most of our agriculture uses land and resources to feed animals, which are then consumed in wealthy countries.”

Therefore, it is not only the ‘gentle fear of our biosphere collapsing’ and ‘social structures’ disintegrating, that prompted the trio to establish the business, but also the current ‘injustices of the food system’.

Societal and environmental concerns aside, the co-founders also observed a gap in the plant-based market – a sector dominated by alternatives to processed meat products. “We really wanted to eat plant-based meat alternatives that weren’t burgers or sausages,” added Hrovat.

Juicy Marbles has indeed set itself apart with its focus on raw, plant-based steak analogues. And the start-up is starting with ‘the most premium cut of them all’: filet mignon.

The technology

The biggest challenge in mimicking conventional steaks is in achieving the ‘right fibre alignment’ and ‘intramuscular fat structure’ – otherwise known as marbling, the co-founders explained. “The most expensive steaks in the world are known for their lush marbling. It takes a lot of energy and a rare breed of cow to attain that,” said Sincek.

At the same time, acknowledging that steak-eaters love the ‘rich, fatty marbling’ present in whole cuts, the co-founders knew they wanted to incorporate this sought-after element.

“We were looking at existing technologies out there, like 3D printing, lab-grown meat and others, and found them to be too complicated, too slow, or had too many behavioral barriers. That’s why we developed our own original machine – lovingly called the Meat-o-Matic Reverse Grinder 9000 – which combines a couple of existing technologies, to which we have modified and added some our own innovations,” Sincek explained.

“Essentially, we now have a machine that enables us full control over fibre alignment (texture), intramuscular fat structure (marbling), flavours, aromas, and other key meat parameters.”

Juicy Marbles achieves all this with its main ingredients: soy and wheat protein, unsaturated sunflower seed oil, beetroot colouring, and natural flavours and aromas. The sunflower oil helps the start-up achieve the texture of the marbling.

The co-founder stressed that its marbling is not for aesthetic purposes only. “It behaves as marbling does in animal meat – it adds a lot to the juiciness and serves as a flavour carrier…”

Achieving a meat-like taste in the kitchen

Of course, mimicking meat analogues is not all about texture. Taste is a key element, and one that Juicy Marbles achieves by using flavours and aromas from a combination of plant extracts.

“Achieving a similar taste to conventional meat comes down to rigorous combination testing and [edging] ever more towards ‘the read deal’,” Travnik told this publication. “Luckily, there are many amazing companies doing groundbreaking work in natural plant flavour synthethis, consequently enabling companies like ours to have an easier start. Also, the marbling plays a huge role.”

Taste is also enhanced by the cooking method. Unlike a majority of plant-based meat analogues, Juicy Marbles’ offering is raw and unseasoned – waiting for the ‘home chef or grill master’s unique touch’.

“We can’t expect a necessary global diet shift towards plant-based without a wide variety of plant meats that will not only enable the continuation of culinary traditions, but also enable a well-balanced and wholesome diet,” added Travnik.

Sustainability and nutritional profile

While on the topic of health – both human and planetary – FoodNavigator asked the co-founders how their product compares to conventional steak on both counts.

“As with most plant-based products, ours is immensely easier to produce and uses significantly fewer resources [than conventional meat],” said Hrovat. “Especially looking from the point of view of the tenderloin. There is only one tenderloin per cow, and we know how much goes into raising a single cow.

“For every 100 soybeans fed to a cow, only three reach human bellies. We skip the cow.”

And from a nutritional standpoint, the start-up is also confident its product is healthier than conventional meat.

“Our product is similar when looking at the nutritional label with a similar protein/fat ratio – with the only difference being that our marbling is made out of sunflower oil and therefore has less saturated fats,” explained Sincek.

“It’s definitely much healthier than conventional red meat, especially the cheap kind most people eat.”

While Juicy Marbles has not undertaken comparisons with other plant-based products on the market, it said soy – one of its key ingredients – is a ‘super nutritious superfood’ in all respects.

Further, as its meat alternatives are raw and unseasoned, Sincek said they can better integrate into a healthier, more wholesome diet than some of its competitors.

Commercialisation strategy

The start-up is kickstarting commercialisation with a direct to consumer (D2C) model in the US and Europe. As the company is working with known ingredients, it does not have to encounter any ‘significant regulatory hurdles’.

When Juicy Marbles ‘ramps up’ production, it foresees retail channels as its ‘most likely next step’. Concerning scalability, the Sincek said it is ‘very much’ on the trio’s mind. “If our mission is to reach a responsible food system as fast as possible, we need to innovation on the technological frontier as well.

“If we developed an immensely expensive and complicated way to make steaks, we would have a long journey ahead of us to make them affordable. Our process and technology adhere to this.”

While the co-founder admitted scaling proprietary technology is ‘not the easiest thing’, it is necessary ‘if you want to break the mould’ and ‘bring something new to market’. “We are very fortunate to have found amazing scaling partners and we expect to complete the first phase of scale up by the end of April 2021. This will increase our production ten-fold.”

As Sincek suggested, affordability and accessibility are key if the start-up wants to reach the masses. As Juicy Marbles scales up its production, it will be able to bring down the price: “Eventually, we’ll be able to make the most premium meats attainable for everyone.”

Currently, due to its production capacity being ‘symbolic’, Juicy Marbles is selling its tenderloin at a ‘super-premium’ price of $150 each. The start-up’s next target is to bring this down to price parity with store-brought meat, revealed Travnik.

“In two years’ time, we’d like to become cheaper than conventional meat.”