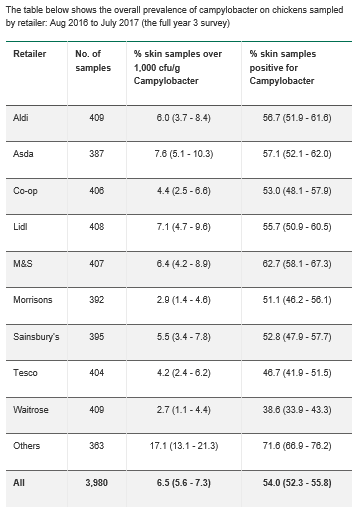

The agency said 54% tested positive in full year results from the third annual retail survey - August 2016 to July 2017 – based on 3,980 whole chickens sampled at retail.

There was a decrease in the percentage of chickens positive from 59.6% during August 2015 – March 2016 to 52.7% over the same period a year later.

The percentage of chickens with high levels of Campylobacter (over 1000 cfu/g) was 6.5%.

Last period of third annual survey

Between April and July this year chickens with this level of the pathogen was 5.9% and the percentage positive was 56.9%.

Changes in prevalence of contamination could be due to improvement or deterioration in the performance of industry, regular seasonal variation or effects such as fluctuations in the weather.

It is the final time the top nine retailers (based on market share) will be included in the annual survey.

The ‘Others’ group, consisting of smaller retailers and butchers, had a higher prevalence (17.1%) of skin samples over 1,000 cfu/g Campylobacter compared to the nine retailers.

Asda had a prevalence of 7.6%, Lidl of 7.1%, M&S of 6.4% and Aldi of 6%.

Percentage prevalence of skin samples positive for Campylobacter was 72% for others, 63% for M&S, Aldi and Asda at 57% and Lidl at 56%.

Future surveys will concentrate on smaller retailers, independent traders and market stalls as they are more likely to be supplied by smaller processors.

Results show progress

Heather Hancock, chair of the FSA, said results show industry progress in reducing Campylobacter levels in chicken.

“Whilst we will keep a close eye on the performance of bigger retailers, it means the FSA can now focus our efforts on smaller establishments, where we haven't yet seen the same level of improvement and where more progress needs to be made.”

FSA revised the protocol in August 2016 with samples needing to be 100% neck skin (and not breast skin) and smaller samples 5-10g depending on available neck skin compared to 25g used previously.

The agency said it could not rule out that the revised protocol may be less stringent than the old one.

Richard Griffiths, British Poultry Council chief executive, said results illustrate the work done by the poultry supply chain.

“Poultry producers and retailers have yet again demonstrated a co-operative and responsible approach to tackling Campylobacter contamination by embedding effective and long-term solutions across the supply chain,” he said.

“As the FSA turns its resources to helping smaller producers improve their standards, we are committed to carrying on our work by refining and improving our interventions across the food chain.”

Testing labs were the three Public Health England (PHE) Food, Water and Environmental Microbiology Labs and the Agri-Food Biosciences Institute (AFBI) Lab in Northern Ireland.

Once samples reached the lab, testing was within 24 hours or before 48 hours after sampling. Chickens were tested before or on their use-by dates.

Dr Jacqui McElhiney head of food protection, science and surveillance at FSS, said Campylobacter is the most common cause of food poisoning in Scotland and research shows between 55-75% of infections are associated with chicken.

“It’s therefore important that we continue to work closely with FSA, our sister agency to promote action by the food industry to reduce the levels of contamination in UK-produced chicken.”