Digital twins, digital replicas of real objects, people, systems or processes, can be a boon for R&D. Reflecting their real-life counterparts through a two-way stream of data, they can simulate every stage of a given production process.

This has seen practical applications in food. Majors such as Nestlé and Unilever, for example, have harnessed digital twins for product development.

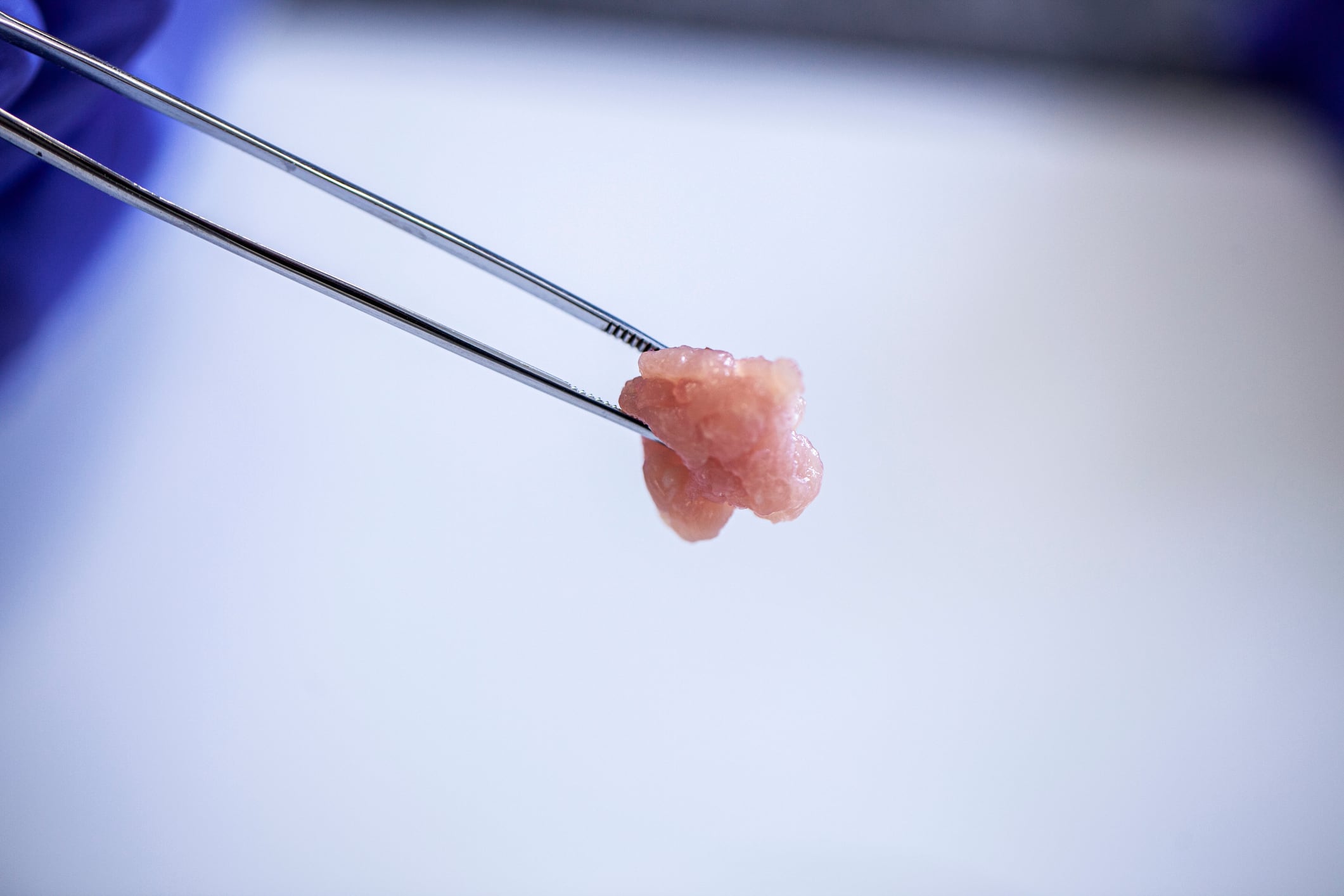

Now, digital twins are being used in cultivated meat. French start-up Gourmey has partnered with DeepLife, a biotech company, to create digital twins of poultry cells for its own R&D.

How are poultry digital twins created?

Gourmey’s poultry digital twins are created through a combination of data from avian cells and AI.

“We begin by collecting sequencing data from millions of avian cells, measuring gene activity across various conditions,“ explains Jonathan Baptista, CEO of DeepLife.

“This data is then fed into Large Language Models (LLMs), which are trained to extract intracellular mechanisms and interactions within the cells. The model is fine-tuned using Gourmey data on media perturbations, enabling it to predict how different molecules will affect the behavior of each cell population.”

DeepLife uses causal AI, a form of AI dedicated to unravelling cause-and-effect relationships in data sets. It uses this type of AI to generate molecular interactions within each cell type which can then be manually explored to make decisions.

Causal AI, explains Baptista, is a “distinct branch of deep learning,” different from areas such as protein design.

How do Gourmey’s digital twins help with R&D?

With digital twins, R&D can be done digitally. “By combining Gourmey’s proprietary cell cultivation platform and advanced analytical tools with DeepLife’s leading digital twin technology, we can now simulate and optimise every stage of production,” explains Nicolas Morin-Forest, CEO of Gourmey.

“Optimising these parameters boosts yield, reduces feed waste, which is a primary cost driver in cultivated meat, and directly lowers production costs.”

Having a digital twin allows Gourmey to fine-tune variables such as media composition and metabolic efficiency before having to plough costs into wet lab experiments.

The composition of the feed, Morin-Forest explains, has a significant effect on the taste and texture of the final cultivated meat product.

With digital twin technology, Gourmey can optimise feed formulations, to deliver feed with a high quality in terms of taste, texture and nutritional value.

“Because we can simulate these changes virtually, we accelerate our R&D cycles and reduce the costs associated with traditional trial-and-error. Much like how animal feed impacts the quality of conventional meat, our digital twin helps us precisely tune cell nutrition to deliver consistently high-quality products.”

DeepLife’s mission beyond drug discovery

DeepLife usually operates in a totally different area, creating digital twins of cells for drug discovery. Why has the company decided to venture into the world of cultivated meat?

For CEO Baptista, it’s all about purpose. “DeepLife’s primary mission is to address one of humanity’s greatest health challenges: developing cures for the most complex diseases within the next decade,” he explains.

“This involves cell engineering–identifying diseased cells and using virtual models to restore them to a healthy state. Similarly, Gourmey is tackling another critical health challenge–sustainable food production – that can be addressed using cell engineering to optimise cell culture for the food of tomorrow."