Hamburg-based biotech MicroHarvest is leveraging the ‘power of microorganisms’ to produce single cell protein for the B2B ingredients market.

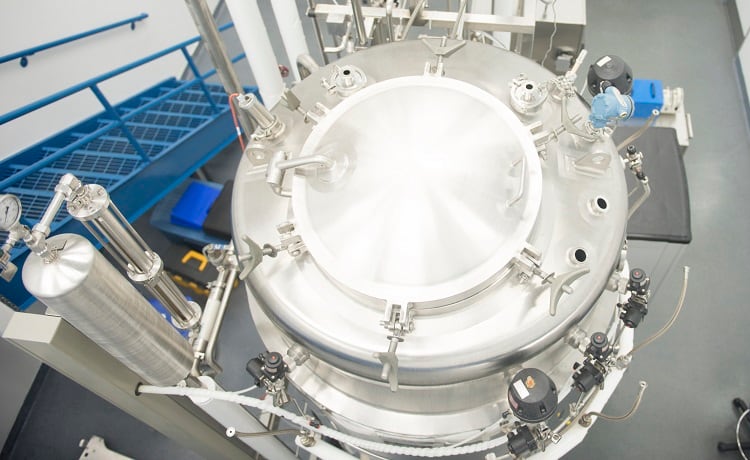

The technology is founded on microbial fermentation. Production begins with the start-up’s bacterial strain and growth medium, before the fermentation process encourages biomass ‘growth’. After this stage, the protein can be harvested.

All this, the company told us earlier this year, can occur in one day – making it the ‘world’s fastest’ protein production system.

Now, having secured €8.5m in Series A funding, the start-up is making moves to increase the scale of its fermentation process.

The ‘easiest’ and ‘most scalable’ process

The funding round was led by Astanor Ventures and Happiness Capital, with participation from Faber and FoodLabs.

“We are thrilled to partner with these eminent funds. We have a strong shared vision for creating impact to our food systems, using the power of nature,” said MicroHarvest co-founder and CEO Katelijne Bekers. “Together we can deliver impact at scale, bringing the faster protein production system to commercialisation.”

The Germany-headquartered company will use the new funds to expand its R&D team, construct a pilot plant in Lisbon, and ‘accelerate’ towards commercial-scale production.

After a ‘successful acceptance trial’ this year, the start-up says an at-scale production trial will yield product to perform further application trials, with the aim to enter the market in 2023.

Investor FoodLabs said it was ‘impressed’ by what the MicroHarvest team has achieved to-date. “There are only very few start-ups solving the problem of sustainable protein production on a large scale.

“MicroHarvest’s approach is by far the easiest and most scalable way to produce sustainable protein that we have come across, with applications across the whole protein value chain,” said FoodLabs’ Christian Guaba.

Feed, food, and pet nutrition

Indeed, the start-up is not blinkered towards protein for human consumption only. Possible applications along the whole protein value chain range from animal feed to direct application in human food and pet food.

“We will show within a niche market in animal feed that we can scale, build our reputation, and then move into the next market,” Bekers told FoodNavigator in April.

Once it has entered feed and pet food markets, MicroHarvest plans to turn its attention to the protein ingredients sector for human consumption. According to BCG, the alternative protein ingredient market is valued at $14bn, and is expected to grow at a CAGR of 14% to 2025.

By the end of the decade, the start-up plans to be operating in aquafeed, human nutrition, pet food, and specialty micronutrient feed markets.