The demand for environmentally friendly packaging solutions is increasing, and both paper manufacturers and brand owners of consumer packed goods are looking for new innovative raw materials to develop future-oriented packaging solutions.

Packaging is a complex topic, though. Reliable raw material availability, consistently high printing and processing quality, smooth integration into existing production processes and low-price volatility are of great importance for paper and packaging manufacturers, as well as for printing companies.

At the same time, brand manufacturers want to stand out from the competition with their products on the retail shelf by offering innovative, sustainable and appealing packaging solutions, and create consumer preference without having to compromise on functionality or price.

Regulatory requirements such as the EUDR (EU Regulation on Deforestation-Free Products) or the PPWR (Paper and Paper Waste Regulation) contribute both opportunities and complexity. The change of existing paper and packaging material to more innovative solutions thus presents certain challenges that new alternative fibres for packaging material must overcome to be relevant. With BeetKraft®, Südzucker aims to offer a solution for exactly these challenges.

An alternative fibrous material for paper

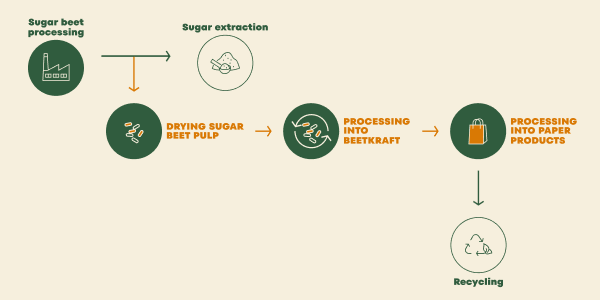

BeetKraft® is made from sugar beet pulp, a by-product that is obtained during the annual sugar production and processed into a high-quality substitute for wood-based pulp using a patented refining process.

Since the end of 2024, and following a collaboration with technology partner Zelfo Technology GmbH and Simply By Nature, Südzucker is now producing industrial quantities of BeetKraft® at a demonstration plant in Offstein, Rhineland-Palatinate, Germany.

BeetKraft’s suitability as an alternative fibrous material for the production of different paper qualities was examined and evaluated in collaboration with PTS (Papiertechnische Stiftung) in Heidenau, a highly respected institute in the paper industry. During the production of paper samples with up to 40% BeetKraft®, the material’s visual and technical properties were found to be very convincing.

After a material screening on a laboratory scale, trials were carried out with various materials in combination with primary and secondary fibrous materials to produce different paper qualities on the PTS pilot paper machine, as well as a production run under real conditions in a paper factory.

The tests have brought up lots of interesting insights, confirming BeetKraft’s suitability for a wide array of packaging solutions. During testing, results showed an increase in roughness as well as an increase in air permeability. In addition, due to the unbleached fibre character, the packaging has a more natural-looking colour. Consequently, a high-quality print image can be maintained.

Functional improvements in paper products

Various product properties were important for Südzucker from the outset when developing BeetKraft®. These include functional improvements over classic wood-based pulp for paper, food safety, recyclability, easy integration in existing processes and no negative impact on continued FSC-certifiability of the final paper packaging solution. During the trials and tests it was found that BeetKraft® offers exactly that.

- BeetKraft® strengthens paper and offers the same or even better stability than conventional wood fibres. Depending on the end use, an increased SCT value (stiffness) of up to 11% is possible. Further improvements are still being worked on.

- Replacement of up to 40% of the classic, primary wood fibres in the paper recipe, while simultaneously increasing the stability of the cardboard and paper.

- Possibility to reduce the overall weight and grammage of the packaging solution.

- BeetKraft® offers consistently high quality for paper and cardboard for reliable and even printing results.

- BeetKraft® can be integrated into existing production processes in the paper industry and can be reliably processed.

- BeetKraft® is food-safe and can be used for packaging of dry, non-greasy foodstuffs.

- Final packaging using BeetKraft® can be recycled, e.g. via waste paper recycling.

- Year-round and plannable supply and thus reliable sourcing and reduction of dependencies on world markets concerning packaging raw materials.

- No negative impact on FSC-certifiability.

Regional, Southern-German sugar beet cultivation

Being obtained from the sugar beet, a crop that is grown in crop rotation and harvested annually, BeetKraft® is an innovative product obtained during the full valorisation of the sugar beet. In addition to being used as animal feed and for energy recovery, sugar beet pulp is therefore now also refined into BeetKraft®. The product has a brownish colour due to its origin, which ultimately gives the final kraft paper, cardboard or container board a natural-looking colouring.

Wide range of applications

BeetKraft® can be used for a wide range of applications such as:

- Kraft paper Providing higher strength and durability. At the same time, the total grammage can be reduced depending on the application.

- Cartonboard Ensuring stable, high-quality cartonboard that is highly suitable for displays and product packaging.

- Containerboard Maintaining or improving the stability of containerboard providing a high-quality solution for the production of robust corrugated packaging and transport boxes.

The BeetKraft® product is firmly integrated in the paper structure; there are no negative effects due to fibre tears or dusting during processing. The fibre structure is not weakened or negatively influenced by the use of BeetKraft® and thus subsequent paper processing can run smoothly.

The suitability of the product has already been tested in several paper weights and different packaging and applications, such as 1kg sugar bags, sugar sticks packaging, carrier bags, paper sheets in various grammages, flyers and brochures with highly satisfying results.

Collaboration to support packaging needs

The launch of the product does not mark an end to the development phase, though. Südzucker is continuously working on developing a wider variety of grammages, refinements and further improving the potential of SCT-values, as well as looking into other packaging solutions that could use BeetKraft® as a substitute for classic wood-based pulp.

Südzucker is always happy to discuss packaging needs and sampling with you and support customers in application and integrating BeetKraft® into existing production processes.