COVID-19 has highlighted the vulnerability of some businesses. SIG, a leading systems and solutions provider for aseptic carton packaging, discusses why agility and flexibility are more imperative than ever for the food and beverage industry and not just a result of the pandemic.

With increasing megatrends, such as rising global consumption, health and convenience, food trust and transparency, sustainability and more, food and beverage manufacturers are under pressure to not only meet today’s consumer needs but react quickly to changing demands. The question is just how can you deal with unforeseen crises as well as continue meeting ever-changing trends?

High flexibility – high speed

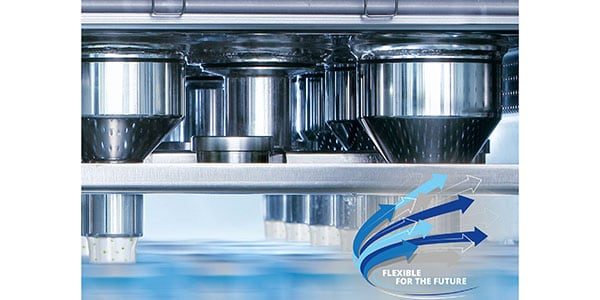

Traditional wisdom dictates that when flexibility in assets goes up, speed and efficiency will go down and vice versa. The key is to ensure both aspects can increase. Flexibility and efficiency mean having the right production and filling setup in place with the fastest possible change-over times for formats, volumes and designs, together with filling machines that can handle multiple product variants.

Abdelghany Eladib, Chief Operating Officer, SIG Combibloc Obeikan, said: “This is precisely what we offer at SIG – high flexibility and high speed – meaning manufacturers do not only meet their current product needs, but they can also quickly react to changing consumer demands and continually meet growing trends.”

Meeting every price point

Another key challenge that COVID-19 has solidified is how to flexibly and quickly meet every consumer price point due to rising unemployment and a drop in spending power. In the global pandemic, billions of people have had to rethink the way they live and work.

Widespread states of lockdown, quarantine, isolation and social distancing are expected to have a long-lasting and scarring effect on economies around the world. This means an increasing loss of business and unemployment, resulting in a marked drop in consumer buying power. This is impacting how people choose and shop products, so brands and producers need to consider whether their portfolios are aligned with the needs of post-corona consumers.

Martin Schmedes, Strategy & Marketing Director MEA, SIG Combibloc Obeikan, said: “With an increasing strain on budgets, many will be forced to continue basic or frugal shopping for some time. But it’s important to also remember that following a long period of monotony and restriction, with limited choices and a slowdown in launches, many consumers will actually be looking for new products and added-value experiences. It becomes clear that a one-size-fits-all approach to products won’t work today. Producers need maximum flexibility on their filling lines with the ability to quickly switch between different formats and volumes on the same machine.”

Jasper Boers, Head of Technical Services Middle East & Africa, SIG Combibloc Obeikan, commented: “That’s why SIG delivers the most agile and flexible filling system possible, enabling customers to fill every kind of product from affordable to premium. It’s quick and easy to switch between different formats, volumes, designs and products. For instance, customers can use a single filling machine to fill carton packs in our combibloc, combifit and combistyle formats with the same base dimensions, meaning they can make a product more or less premium in appearance and ingredients. Our machines even allow customers to fill up to nine different volumes with a single system – and it only takes a few minutes to complete the changeover. Also, if a customer sells internationally, or makes the same product under two different brands, he’ll be able to change pack designs without stopping production.”

Beyti, the joint venture between Almarai and Pepsico in Egypt, opted for SIG machines and leveraged the full benefits of flexibility, producing packs with different sizes. The size flexibility of the CFA 1224 line allows the opportunity to launch new sizes at more affordable prices with an option to change between nine pack sizes while maintaining the highest levels of quality. The product flexibility allows the ability to fill milk and juice with fast change over between products with zero waste. Lastly, format flexibility differentiates products on the shelves. Beyti is one of the key players in the Egyptian market with an increased market share.

Jasper Boers concludes: “The unique aspect of SIG’s filling technology and system is that customers can flexibly respond to the changing needs of consumers without ever sacrificing speed. Producers often must compromise the speed of their output if they want to increase the flexibility of their line, which could result in having two separate filling lines – one for high flexibility and one for high speed. But with SIG, we guarantee both high flexibility and high speed on the same filling line. This means customers can match products to the right consumer price point and the required volume fast and flexibly.”