For centuries, cooks relied on pectin to thicken jellies and jams. Today, this time-tested ingredient is sparking new innovations, as formulators unleash its thickening, gelling and protein stabilization properties on a broad array of food and beverage applications.

Part of its appeal lies in its upcycled origins. It’s made from the leftovers of juice production – apple pomace and citrus peels. Couple these renewable roots with consumers’ positive perceptions and it clearly checks the “label-friendly” box coveted by manufacturers. On top of those attributes, pectin enables some of the biggest trends in food production, aligning with desires for plant-based, reduced-sugar and vegan/vegetarian formulation. Little wonder the versatile, functional texturizing ingredient remains in-demand 200 years since it was first isolated and named.

For consumers, pectin likely evokes fond memories of tasty spreads created in Grandma’s kitchen, but in the plant world, pectin is a key structural component. Found in most plant cell walls, it binds with water to become nature’s “glue,” helping to hold everything together. It performs similar functions in food and beverage applications, but thanks to advances in processing technology and R&D investments by ingredient suppliers like Cargill, formulators now have access to a wide array of finely tuned pectins, with varying gel strengths, setting temperatures and rates, and viscosities for maximum process and product development flexibility.

Finding the perfect pectin

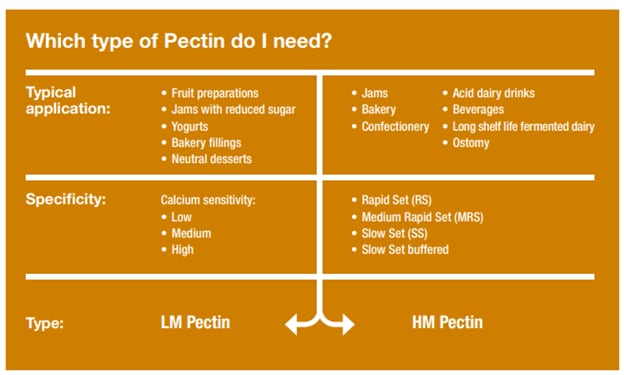

Today’s pectins can be broadly categorized as either high methoxyl or low methoxyl products. High methoxyl (HM) pectins need a high solids content (greater than 60%) and a low pH (2.8-3.5) to form a gel. They’re often used to create chewy confections and thick jams, and also have application in reduced-sugar beverages, where they add viscosity and improve mouthfeel.

In addition to their thickening and gelling properties, HM pectins make acidified dairy beverages possible. Left unprotected in acidic conditions, dairy proteins will stick together, forming large, unappealing clumps. HM pectins form a protective “net” around the proteins, preventing them from aggregating together.

Low methoxyl (LM) pectins work a little differently as they rely on calcium to form a gel. This means total soluble solids are less important, making LM pectins the perfect choice for many reduced-sugar applications. LM pectins can be further divided into two distinct groups: conventional (LMC) and amidated (LMA). LMC pectins are highly dependent on calcium to form a gel, creating networks that resist high temperatures for excellent baking stability. In contrast, LMA pectins are more tolerant to calcium variability and create thermoreversible gels.

These general classifications serve as a good starting point for pectin selection, but developers should also consider additional characteristics, such as setting temperature and viscosity. Cargill’s suite of UniPECTINE® products provide a wide range of textures and rheological properties, making it possible to match manufacturers’ specific gelation, setting speed, viscosity, mouthfeel or stabilization requirements.

When necessary, pectins can also be combined with starches, fibers or carrageenan to achieve specific texture goals. Texturizing experts who understand how these components act independently and in combination can help formulators find the right combination of ingredients for their unique needs.

Application opportunities

Fruit applications remain the single biggest space for pectin’s use. Cargill’s complete range for this space exists of HM, LMA and LMC pectin solutions for all types of jams, jellies and fruit preparations varying in pH and fruit inclusions. In jams, jellies and fruit preparations, HM pectin enables excellent fruit suspension and distribution and ensures a consistent texture. Cargill’s line includes HM pectin solutions specially designed for use in bakery products. These options marry texture requirements with bake stability and can be used in a wide range of fillings and coatings. Common fruit applications include:

- Standard jams and reduced-sugar jams

- Gelling sugars for homemade jam

- Fruit preparations for yogurts

- Water jellies

- Bakery fillings (post-bake and bake-stable)

- Glazes and decorations

- Fruit chips and fruit snacks

Pectins are also seeing more use in dairy and plant-based dairy alternative applications, where they help control syneresis. In acidic and neutral dairy and plant-based dairy alternatives, LM pectins can provide a gelled or creamy texture. HM pectins are the choice for acidic dairy drinks, where they protect and stabilize milk proteins and provide a pleasant mouthfeel. Common examples of these pectin-containing products include:

- Dairy desserts

- Acid dairy drinks

- Yogurts and sour creams

- Long shelf-life yogurts and creams

- Plant-based dairy alternatives

Confectionery manufacturers rely on pectin for great texture and flavor release, especially in jellies and gummies. HM pectin is ideal for high sugar acid jellies (coated or not) and offers excellent firmness and flavor release, along with a smooth, brittle texture. LM pectin is the choice for non-acidic conditions, where it’s known to provide a tender texture. The plant-sourced ingredient supports vegan/vegetarian formulation and offers improved shelf-life quality, especially in warmer climates. Confections that are perfect for pectin include:

- Soft candies such as gums and jellies, toffees, caramels, fudge, chewy candy and aerated products

- Gelled candie

- Fruit paste and fillings

Pectin has also developed a following among beverage manufacturers as it helps replace mouthfeel lost in sugar-reduced beverages. The best pectins for the applications combine thickening and viscosifying properties with good acid stability, enabling use in low-calorie soft drinks and fruit juices. Pectin often makes an appearance in these beverages:

- Soft, diet and fruit juices

- Juice drink concentrates

- Nutritional fruit drinks

- Flavored waters

Reliable, sustainably-sourced supply

Given its versatility, functionality and label appeal, it’s no surprise demand for pectin is at an all-time high. In response, Cargill opened a $150 million HM pectin plant in Bebedouro, Brazil, in September 2021. Built in the heart of Brazil’s citrus-growing region, the new plant’s proximity to citrus fields ensures an abundant supply of fresh fruit peels – the raw material required for premium pectin production.

The Brazilian plant also keeps with Cargill’s commitment to sustainably source ingredients. This includes its proximity to citrus suppliers and their Rainforest Alliance certified farms, which helps minimize CO2 emissions from raw material transport and promotes regenerative agriculture practices. Taking sustainability one step further, the Bebedouro plant is powered by thermal energy generated from biomass and biogas.

The new facility compliments Cargill’s three other pectin factories located in France, Germany and Italy, and spreads the company’s production across two continents. Quality teams at all four locations employ rigorous test protocols to help ensure consistent quality, including application tests that verify the actual performance of our product in specific consumer goods. These state-of-the-art production facilities allow Cargill to unlock the full potential of pectin. As a result, it’s possible to offer solutions that create unique textures across a wide range of setting temperatures and pH levels. While today’s pectins still make a great jelly, they also do a lot more.

To learn more about Cargill’s pectin portfolio, visit www.cargill.com/unipectine