Unlike composite packaging solutions that combine two or more material types (think aluminum-lined paper-based wrapping for brie, or the multi-layer film on sliced cheese packs), mono-material-based packaging has virtually zero barriers to recycling. This is because it is made of a single material, so recyclers do not need to separate the lining from the paperboard, for example.

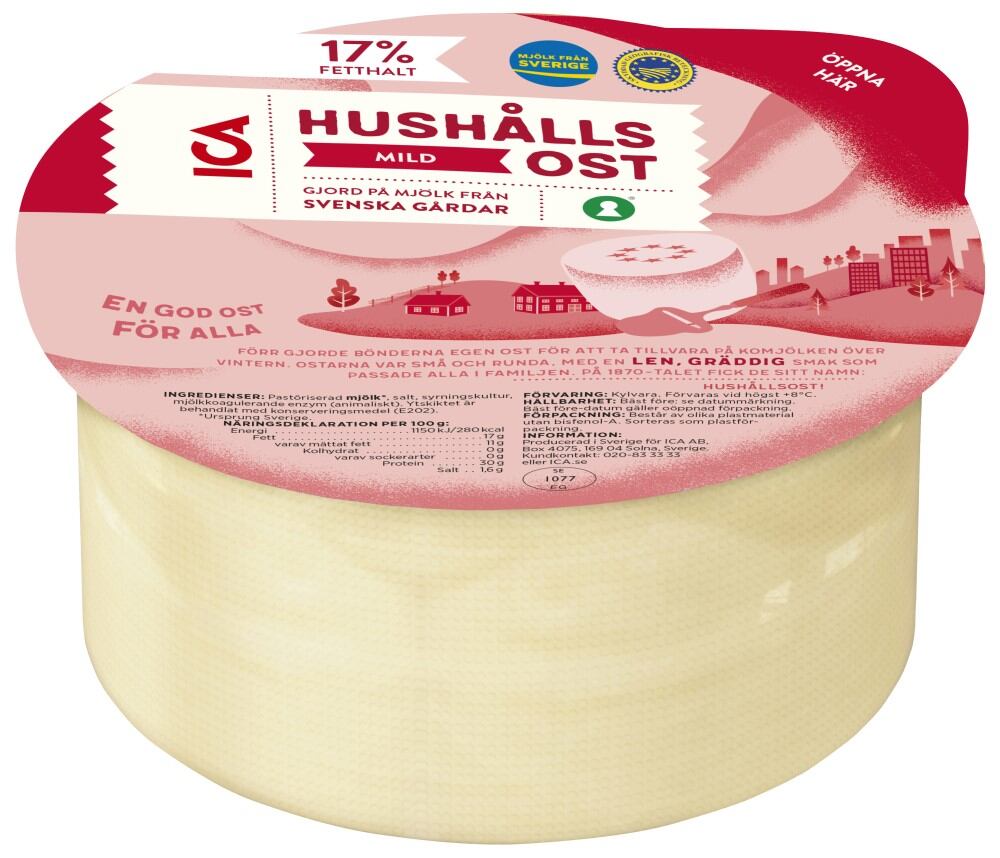

Packaging manufacturer Mondi has recently come up with a mono-material polypropylene-based packaging that provides high oxygen and water vapor barrier to ensure freshness. Comprising mono-material base, web and lidding film made of polypropylene (PP), the packaging is produced and printed by Mondi before being converted for 1kg and 2kg blocks of Hushållsost cheese made by Skånemejerier and sold as a private-label product by Swedish supermarket ICA. However, the packaging is suitable for a wide range of hard and semi-soft cheeses, or other food-grade applications, we were told.

“This solution could be used for any cheese or other applications, more or less,” explained Helene Brynell, Regional Sales Nordic Consumer Flexibles at Mondi. “It might be recommended to change the thickness or other details in the formulation depending on, for example, barrier needs, shape of the product and production machines. But a mono PP is suitable for many different applications in the food industry and non-food industry. That is what makes it so fantastic.”

The challenge for Mondi was to develop a mono-material packaging that could properly protect the product inside, providing suitable barrier properties against oxygen and water vapors to keep the cheese fresh on the shelf. “The packaging has to protect the product while offering a more sustainable solution,” Brynell said. “Through the mono-material structure the packaging is designed for recycling, aiming to keep the packaging materials in circulation.”

The plastic previously used for this cheese had previously been non-recyclable, a Skånemejerier spokesperson confirmed for DairyReporter.

Ingemar Jönsson, Packaging Manager at Skånemejerier, added: “Our collaboration with Mondi has been a thorough process: we started our first test and trials in 2019 and are delighted to be bringing this fully recyclable packaging to market before the end of 2023. The great working relationship we had, meant that we were able to adapt materials and machinery efficiently, resulting in a successful, fit for purpose solution. We have strong, effective and good-looking packaging that keeps materials in the loop and responds to consumer demands for more sustainable solutions.”

The release of the new packaging coincides with the opening of a new recycling facility, Site Zero, where used plastic from across both Sweden and Finland will be processed. Brynell explained: “Thanks to the mono-material design, Site Zero will be able to effectively sort the solution for recycling, working towards a circular economy.”

Rickard Jansson, Development Engineer at Swedish Plastic Recyclin, added: “We are very positive about the new packaging that Mondi has developed together with Skånemejerier for ICA. By using mono-material film instead of laminate consisting of different types of plastic, we can sort out and recycle the packaging that is left in the system, thus avoiding incineration. With Site Zero's new technology, this PP film-based packaging will be able to become new products, which has not been possible in any facility in Sweden before. It provides circular plastic flows that reduce the need for fossil raw materials and combustion.”

Mondi’s new packaging also won the 2023 PackNorth Award in the food category and was recognized at the Empack tradeshow in October in Stockholm, Sweden.