Israeli start-up Profuse Technology does not make cultivated meat itself, but rather supplies media supplements and growth protocols to this relatively young sector. The small molecule-based mixture, previously described by the company as a ‘Profuse cocktail’, is added to the growth or differention media to encourage protein growth.

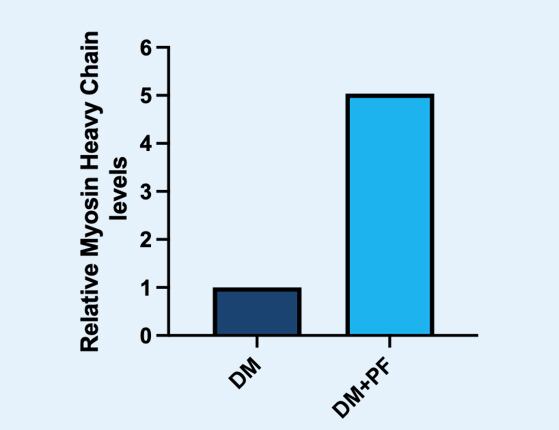

In 2D environments Profuse Technology has observed significant gains, with up to two and a half times more muscle and five times more protein in cultivated meat. The ‘cocktail’ has also helped reduce production times.

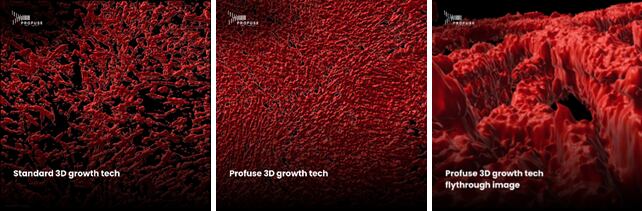

Now, the start-up is celebrating a ‘breakthrough’ in 3D environments. “It is essential to recognise that the heart of meat production lies in muscle growth, as meat equals muscle,” explained CEO Guy Nevo Michrowski. “The ability to cultivate meat cost effectively and at scale hinges on adopting 3D growth methodologies involving scaffolds and microcarriers.”

‘Closely mirroring conventionally farmed meat’

The company claims its technology is ‘poised to reshape the landscape’ of muscle production in 3D format on scaffolds. In facilitating the production of ‘fully mature’ muscle tissue in a 3D environment, it says it can help innovators closely mirror conventionally farmed meat.

Scaffolding technology allows for the development of more complex cultivated meat products, such as filets and steaks. When used in this 3D environment for chicken and beef cell cultivation, Profuse says its supplements can achieve an 80% reduction in the duration of the muscle growth phase to only 48 hours.

Growth acceleration aside, the start-up says its technology also elevates muscle tissue protein content by a factor of five.

“This achievement is the culmination of a year of dedicated hard work aimed at optimising methods for muscle growth, harnessing the full potential of our media supplement within the demanding 3D system based on an edible scaffold,” Michrowski told FoodNavigator.

Whether used in 2D or 3D environments, Profuse Technology estimates it can help cultivated meat players reduce production costs by up to 40%. “We have accomplished this because we maintained consistent improvements, including reduced time, enhanced conversion efficiency, and consequently, higher muscle mass,” explained the CEO.

Moving from R&D to commercialisation

Profuse Technology is currently supplying its supplements to the cultivated meat industry, but remained tight-lipped on company names.

“We are actively collaborating with cultivated meat companies that focus on muscle growth, as well as other technology firms specialising in the development of cell lines, scaffolds, and media,” revealed Michrowski.

As to how Profuse Technology’s supplements may impact cultivated meat players’ regulatory approval process, the CEO stressed that the majority of the molecules used in its supplements are of food-grade quality.

“We are currently in the process of compiling a comprehensive safety dossier, which will enable our customers to use our products confidently. We are regulated as a non-detectable manufacturing aid.”

Overall, regulatory approval of cultivated meat products is on the up, with cultivated chicken now on the table in both Singapore and the US. Michrowski expects a ‘handful’ of additional cultivated meat compares to secure regulatory approval in the US by early 2024.

Market competition?

As is often the case with young, exciting sectors, entrepreneurs can be drawn to the space with B2B opportunities in mind. Ever After Foods, for example, has developed bioreactor tech to boost productivity for cultivated meat players. Multus Biotechnology is developing a growth media factory for cultivated meat, and CellRev is wanting to rejuvenate spent cell culture meat.

But as to potential competition within the media supplements market, Profuse Technology has yet to come across any rival companies. The start-up does see scope for greater collaboration between industry players, however.

The cultivated meat industry is currently facing challenging times, with companies primarily concentrating on bringing their initial products to market, explained the CEO. “These initial offerings, known as Minimum Viable Products (MVPs), predominantly centre around cell biomass and typically contain a limited proportion of muscle cells and fibres.

“The media providers, who in many cases collaborate with us to distribute the PF [Profuse] supplements, primarily focus on supplying cultivated meat companies with the necessary media for cultivating cell biomass. Consequently, their immediate emphasis is not on developing in-house muscle solutions.

“This situation presents us with an opportunity to provide PF solutions to support them.”