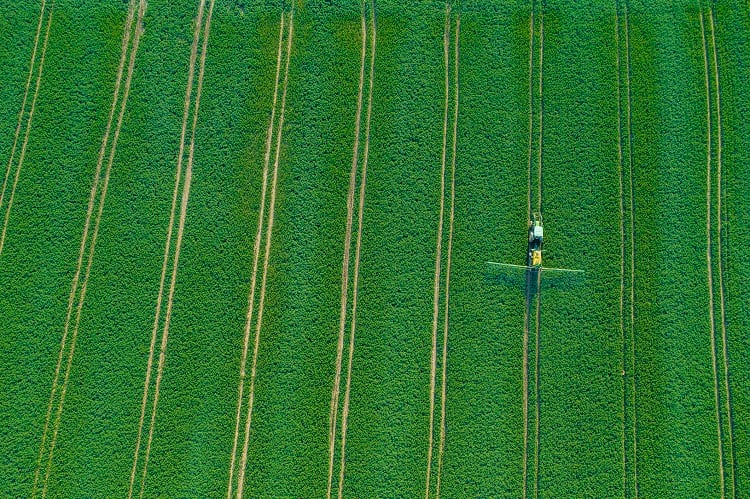

All nine locations of the Bindewald & Gutting Milling Group, together with bread and baked goods maker Harry-Brot, have signed a cooperation agreement to implement Yara’s ‘green’ fertilizer with the aim of reducing CO2 emissions in cereal cultivation.

‘Green’ fertilizer is much the same as conventional fertilizers in that they are also made of nitrate-based minerals and have an identical chemical and physical composition. But the production method is different: in Germany, Yara’s ‘green’ fertilizer is made from green ammonia at its Rostock plant thanks to renewable energy sources such as wind, hydropower, or solar energy.

Collaborating for greener crops, flour, baked goods

The fertilizer will be used on an area of around 1,600 hectares as early as of 2023/24 growing season.

For the Bindewald & Gutting Milling Group, the partnership represents a way of assessing the CO2 footprint of its grain, and tracking its carbon footprint. "Sustainable production processes have been an integral part of our mills and farmers' practices for quite some time,” said Michael Gutting, managing partner of the Bindewald & Gutting Milling Group.

Harry-Brot will transform Bindewald & Gutting Milling Group’s flour into baked goods, thus covering the complete value chain from raw materials to grocery store shelves.

"While we are continuously working on reducing Scopes 1 and 2 CO2 emissions, with short delivery and transport routes and efficient production, we are still dependent on agriculture and our suppliers when it comes to Scope 3 emissions,” explained Norbert Lötz, managing director for Production and Technology at Harry-Brot. “If we succeed, starting with fertilization, we can reduce emissions precisely where a large proportion of our supply chain emissions has always occurred.”

The partnership represents Yara’s first in Germany for its fossil-free ammonia fertilizer. "Our partnership with the Bindewald & Gutting Milling Group and Harry-Brot is a crucial first step to decarbonize German agriculture,” said Marco Fleischmann, managing director of Yara Gmbh & Co. KG. “It is a concrete example of how food production can be transformed in a sustainable way. However, not only all stakeholders along the food value chain are challenged and invited to actively participate in the green transformation of agriculture but also politicians promoting the expansion of renewable energies," adds Marco Fleischmann, Managing Director of Yara GmbH & Co. KG.

Achieving scale: is cost a barrier?

As to whether the cost of ‘green’ fertilizer could prove a barrier to agricultural operations looking to reduce CO2 emissions, Sara Ekström, director of Green Fertilizer at Yara International told us decarbonizing the food chain is reliant on all players working together.

“To decarbonize the food value chain, all players need to work together. The whole food chain must agree on what food to decarbonize first, and on how each step in the chain can contribute. Green solutions – both in the agri-food industry and in other industries – will also require the development of new, green business models. Yara actively contributes to this work together with partners.”

Indeed, transitioning to a decarbonized and fossil free food chain may also entail higher costs, Ekström continued. “Producing green fertilizers requires large investments related to rebuilding plants and increasing renewable electricity sources. In addition, operational costs may also increase, as renewable energy historically has been more expensive than natural gas. However, costs are expected to come down somewhat when we achieve scale.”

Farmers cannot be expected to carry the entire extra cost of the transformation to greener food production, Ekström stressed. “Therefore, the whole food value chain must agree upon a new business model where the extra cost is shared across the value chain or with consumers.”

Overall, Yara does not believe this will not necessarily result in a large increase in the cost of food. The World Economic Forum (WEF) believes costs for end consumers will be very limited and has estimated that the average cost increase for a EUR 20 shopping basket of food will be less than 4%.

Lastly, Yara shared that it is working to expand its geographical presence through its ‘clean ammonia business’. To do this, the company will be using a third-party verified methodology for green ammonia allocation between plants, enabling global availability of green fertilizers.

Consumers are ready for ‘greener’ food and drink

Conventional mineral fertilizers are thought to account for around 2.4% of global greenhouse gas emissions. At the same time, around one-third of the total energy input to crop production goes towards the production of fertilizers.

According to the Intergovernmental Panel on Climate Change, the amount of mineral nitrogen fertilizers used worldwide has grown 800% since the 1960s. The UN expects that volume to increase by 50% by 2050.

Consumer research suggests shoppers are ready for change. With climate change becoming a more knowledgeable topic amongst the general public, an IPSOS study commissioned by Yara gained statistics on German consumer's attitude towards sustainability.

It revealed that 74% of German consumers want product packaging to display the CO2 footprint, and 53% were willing to pay more for food produced with reduced fossil fuels. Using green fertilizer can offer consumers sustainable food from a climate-friendly production, noted the fertilizer producer, and and can reduce grain CO2 footprints by up to 30%.