Over the last year, artificial intelligence capabilities have grown exponentially. Generative AI tools are taking the world by storm, and food and beverage players are paying attention. AI-powered ChatGPT even developed a soda product this year (in just two days), which is now on the market.

But AI is not new. The term artificial intelligence was first inked in 1955 and the concept has been developing ever since. Today, AI is founded on automated machine learning, whereby AI-powered bots can take decisions and give commands for future generations.

CPG major Unilever has been using AI for more than a decade to enhance its product portfolio. The Knorr-to-Magnum manufacturer says it is leveraging its data, computational power, AI, automation, and tie-ups with external partners, to advance scientific fields ‘not by years, but by decades’.

So how exactly is Unilever using AI and big data biology to transform food and beverage?

Uncovering ‘secrets’ in the gut microbiome

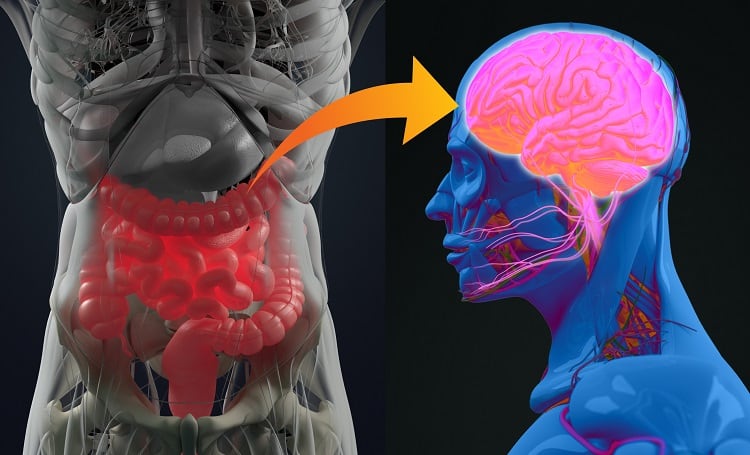

AI and big data are essential to gut microbiome research, according to Unilever. The company believes industry is moving from an age of chemistry to the age of biology and making discoveries about how the body interacts with the microbiome.

“This is only possible because of access to large scale data, machine learning and high-performance computing, making connections the human brain would never have been able to achieve,” explained Dr Samantha Samaras, global vice president science & technology, beauty and personal care R&D at Unilever, at a media briefing in London.

Of the 100trn bacteria in the adult human body, more than 95% of them are located in the gut microbiome. At the lowest estimate, around 90% of health and wellbeing issues have some form of link to the gut microbiome, Carla Hilhorst, chief R&D officer, Unilever Nutrition Business Group, told journalists.

It is well acknowledged that diet can have a significant impact on gut microbiome health and diversity. “That makes it a very interesting space, we can actually improve healthy by our food. And it is super complex…and then on top of that, your gut microbiome is very individual. It’s like your fingerprint. So you need to take those two things into account.

“That’s where big data and AI can really help us to uncover some of the secrets of the gut microbiome.”

Last year, Unilever kickstarted a partnership with microbiome experts at biotech company Holobiome to identify food and beverage ingredients that could positive impact mental wellbeing by targeting the gut-brain axis.

Holobiome brings its discovery platform, which has mapped the microbiome and its influences, to the partnership to identify key bacteria that appear to communicate to the brain via neurotransmitter signalling in the gut. Unilever is bringing its expertise in microbiology, consumer insight and product formulation, as well as its ‘long-term ambition to bring these health-beneficial products to market’.

Holobiome has identified a microbe that produces gamma-aminobutyric acid (GABA), which is known for producing calming effects and is thought to have an impact on anxiety, stress an fear.

Together with Unilever, Holobiome is screening hundreds of food ingredients to identify which ones are capable of feeding (prebiotics) GABA-producing microbes (probiotics) to encourage increased production. The screening process identified a selection of ingredients that have been tested in-vitro. “We now have a smaller selection that we are going to test in [human] trials,” Hilhorst explained. “We hope to find a measurable impact in people.”

‘Working smarter’ in NPD

Big data and digital modelling is also helping Unilever ‘work smarter’ in new product development and factory formulation. “Today, we have game changing technology and tools to strengthen our insights to develop the next level of innovation, but also to help us with scientific discovery,” the R&D chief told journalists.

An increasing number of new product developments begin with in silico testing. In biology and other experimental sciences, in silico refers to experiments performed on computer or via computer simulation. Unilever has employed in silico technology to develop new formulations within its Knorr and Hellmann’s product ranges.

Unilever’s Knorr brand makes soups, seasonings, sauces and bouillon cubes – the latter which typically contains high sodium levels. In bouillon cubes, salt provides taste and structure, but consumers were asking for a healthier product – low on salt but still full of flavour.

Using digital modelling rather than traditional recipe testing, Unilever’s food scientists and chefs analysed millions of flavour combinations in days rather than months. The result was a ‘completely reinvented’ product, we were told. The blend of vegetable has herbs has the taste, texture and structure of a traditional stock cube, but with zero salt.

Knorr’s zero salt veggie stock cubes contain glucose syrup, shea butter, flavourings, onion powder, potato starch sugar, herbs, nutmeg, red pepper, pepper, carrots, lovage root, and turmeric.

The company also used in silico modelling to develop its Hellmann’s Vegan Mayonnaise product. Acknowledging that flexitarian consumers wanted a plant-based alternative that was ‘just as creamy and indulgent’ as Hellmann’s Real Mayonnaise product, the company developed advanced models able to predict the taste, texture and stability of products.

Unilever was able to replace the animal-based emulsifier (egg) with a plant-based alternative (modified corn starch) without needed to conduct multiple recipe tests nor traditional product development trials. It was also able to predict whether the product could run on its existing processing lines.

The Hellmann’s brand also leveraged in silico modelling to develop a new formulation for its Real Mayonnaise Squeeze Bottle. Consumers were concerned about having leftovers in squeeze bottles, so Unilever scientists and product developed reworked the packaging material and product formulation to reduce waste and ‘get more out’.

The ‘Easy-Out’ design is made up of new packaging and oil coatings. Neither the taste nor quality of the product is compromised, believes Unilever. The result? A product offering precise dosage, no leakage and that is easy to clean.

Digital modelling and AI is also helping Unilever better manage portfolio analytics. “Having data at your fingertips allows us to continue to optimise the core structure of [our] products,” explained Hilhorst.

This is particularly helpful in reformulation. If an ingredient is no longer available due to supply chain disruptions for example, swapping out that ingredient for another can now be a ‘really fast’ process. “Unfortunately, we live in a world where the supply chain is quite vulnerable at the moment, so we have to do these reformulations quite a bit, [so] having that data is super important.”

Biotech for €1.5bn plant-based pledge

Biotechnology, which at its simplest refers to technology based on biology, is at the heart of Unilever’s fermentation-derived product and ingredient portfolio.

“Biotechnology, if we simplify it, is a process where you take a feedstock (and if it’s food it can be sugar or dairy protein), you select a microorganism (it can be a yeast or bacteria), and then that actually transforms into a product – a product that can have another texture [or taste],” explained Hilhorst.

Being complex processes, Unilever is using its digital capability combined with its scientific understanding to optimise its use of biotechnology. One example in food used by Unilever is its fermented peptides, an ingredient it incorporates into ice cream to help improve product stability within the cold chain, where temperatures can vary.

Biotechnology is also at play in Unilever’s alternative protein portfolio. In 2021, Unilever’s plant-based brand The Vegetarian Butcher entered into a supply agreement with mycoprotein producer ENOUGH (formerly 3f Bio).

The food tech company’s ABUNDA mycoprotein – made by feeding fungi with biomass – uses 97% less feed than beef, 80% less than chickens and 40% less than soya beans. It is also significantly more water efficient, using 93% less water than beef, 55% less water than chickens and 29% less water than soy. ENOUGH reported that its carbon emissions are 97% lower than beef, 80% lower than chickens and 53% lower than soy.

“It’s these kinds of [statistics] that we find super interesting,” said Hilhorst. “And we are continuously expanding the amount of products that we have in our plant-based portfolio, whether that is meat alternatives for The Vegetarian Butcher or Hellmann’s Vegan Mayo, bouillons for Knorr, or vegan ice creams.”

In 2020, Unilever committed to achieving €1bn in sales from plant-based food products by 2025/27, but earlier this year expanded its plant-based meat and dairy alternatives commitment to €1.5bn in sales by 2025.