Autonomous Sensory Meridian Response (ASMR), a rising trend typically seen on YouTube and Instagram, highlights the link between pleasant joyful feelings and specific auditory and visual stimuli. Examples include the Mukbang trend in Korea, which are live-streamed video where viewers watch the host eat.

According to Omya a global producer of mineral ingredients, the trend was the perfect opportunity to explore how its calcium carbonate product, called Omya Calcipur, can help support appealing – and audible – crispness. Omya says its calcium carbonate product can contribute to fortification in a wide range of food and beverage applications thanks to its highly bioavailable properties.

It is also “a real all-rounder” suitable for different technical processes, offering a positive impact on not only health but also sensory qualities, mouthfeel and colour.

When used in snacks and cereals, the particles provide better extrusion and intensify the perception of salty or sweet tastes, the company claims.

It has now conducted a new trial with baked wafers which has revealed how a specific amount of Omya Calcipur can reduce the mass of the wafer by lowering moisture content due to increased heat transfer, ultimately resulting in a crispier end product.

To demonstrate how calcium carbonate can easily improve mouthfeel without negatively impacting taste, Omya carried out a sound analysis which it claims showed a clear correlation between audible crispness and the content of its calcium carbonate product in a wafer. The higher thermal conductivity of the calcium carbonate compared to flour, it concluded, can be advantageous for manufacturers as it allows for a reduction in cooking time.

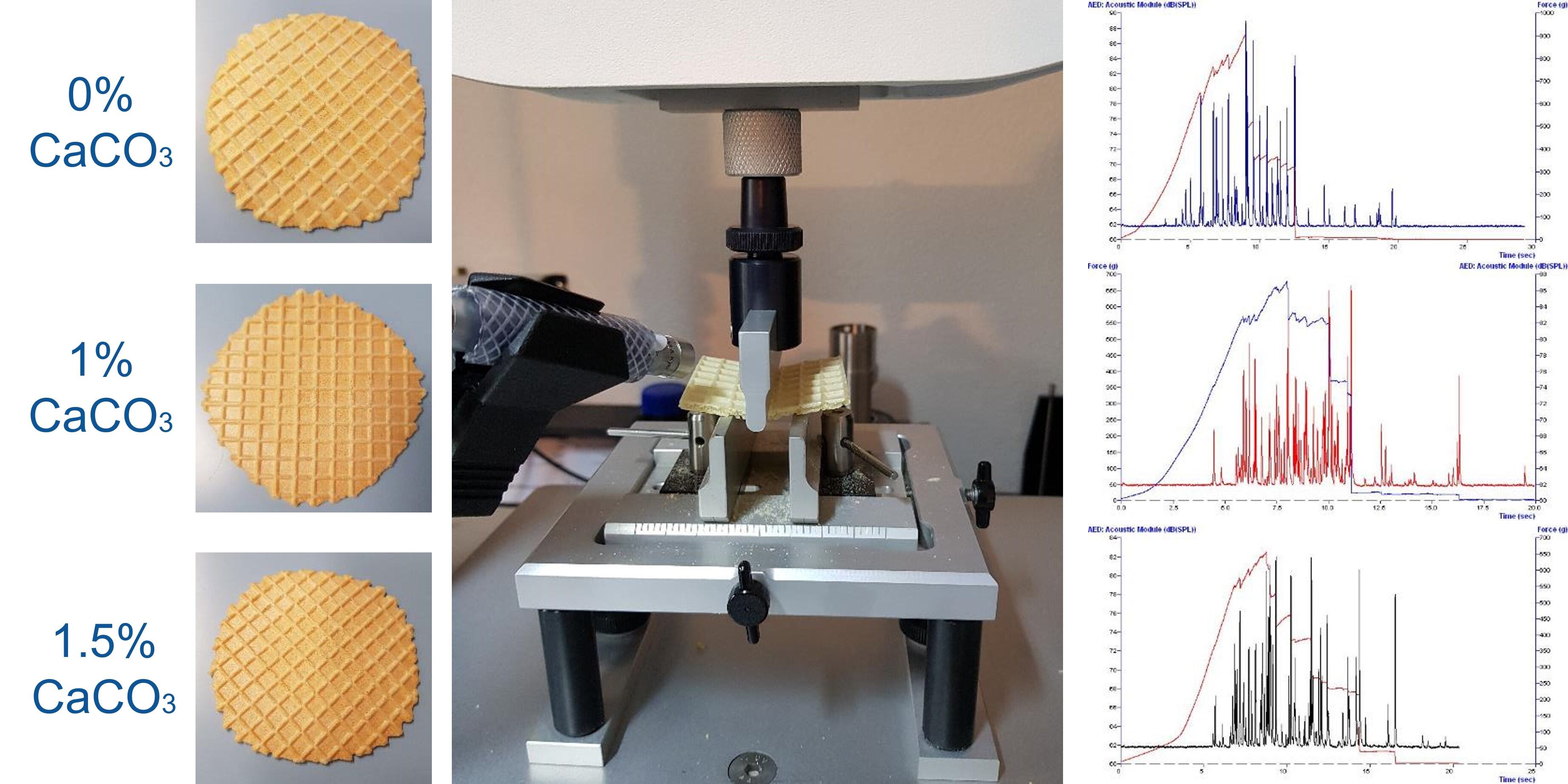

Measurements taken during the trial were weight, texture analysis, moisture content and food consumption noises. Wafers containing three different amounts of calcium carbonate (0%, 1% and 1.5%) were prepared in a norming process, cut into squares of 55 x 55mm and their weight measured. A combination of force measurement and acoustic detection was used to assess crispness, using an Acoustic Envelope Detector (AED) and a Texture Analyzer. Crispness was defined by the number of sound peaks detected during the structural breakdown of the wafer. The texture analysis proved that the firmness of the wafer was not affected by adding calcium carbonate: the maximum force referred to the hardness of the wafer, which stayed constant.

The sound analysis demonstrated that the addition of calcium carbonate significantly elevated the number of peaks and thus the crispness of the wafers. The addition of 1% calcium carbonate enhanced the number of peaks by 29%, while 1.5% addition of calcium carbonate resulted in a 48% increase.

“When it comes to crisp baked goods such as wafers, the sound while eating is key to consumer acceptance. And that’s because perception of product quality, and even taste, are closely connected to acoustics. Our sound analysis reveals how calcium carbonates provide added bite to baked goods,” said Renata Negrini, Technical Service Manager Food, at Omya. “In a world of mass consumption it’s more important than ever for manufacturers to create products that stand out from the crowd.”