Mycoprotein is a protein-rich, fungi-derived ingredient predominantly used for its ‘meaty’ texture in processed meat alternatives.

For the most part, mycoprotein-based alternatives aim to mimic reconstituted animal-based products (think meat-free mince, sausages, burgers and fish fingers), but a new research collaboration between a mycoprotein supplier and a vegan seafood brand is tackling the ‘most attractive’ format: whole cuts.

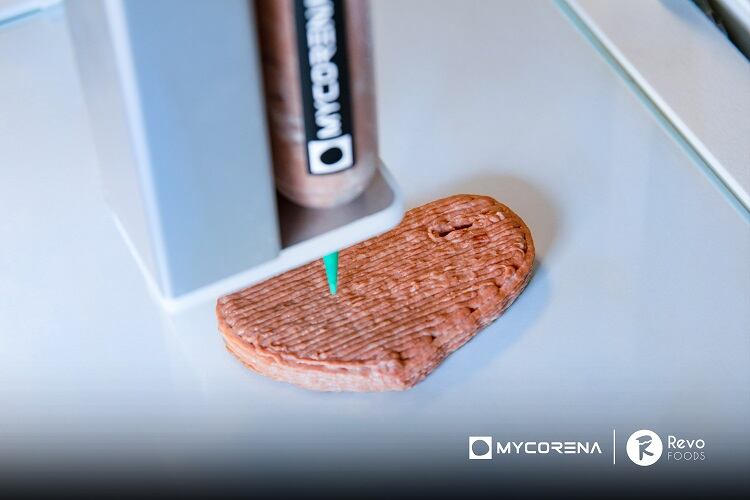

Mycorena and Revo Foods will explore the compatibility of their technologies through the lens of Industry 4.0: 3D printing.

Same strain, new method

Austria-based Revo Foods is no stranger to 3D printing. The food tech start-up developed an ‘ultrarealistic’ 3D-printed salmon fillet last year using 100% plant-based ingredients, which it expects to launch early next year.

In this latest collaboration, Revo Foods is focusing less on plants, and more on fungi.

Aware that meat and seafood alternatives are ‘gaining increased traction’ from consumers, the start-up has observed that whole cut steak or fish fillet are ‘still difficult to produce’. “3D food printing is seen as the most promising technology for producing these high-value products,” according to Revo Foods.

“Healthy vegan products, such as mycoprotein, are of main interest for production of whole cut alternatives due to their inherent fibrous behaviour. This fibrous behaviour could, however, be limiting for certain processing methods such as 3D printing.”

Mycorena is offering up its previously developed and adapted protein, better suited for 3D food printing, to the collaboration. The supplier is using the same strain as for its current mycoprotein ingredient, Promyc, but is using a ‘new method to treat the mycelium’, we were told.

The printable mycoprotein will have a ‘soft fibrous texture’, light colour and neutral taste, which Revo Foods suggested makes it an ‘excellent option’ for meat analogues, especially seafood analogues.

The whole cut potential

Combining the ‘meat-like’ properties of mycoprotein with the ‘unrestricted shaping possibilities’ of 3D food printing could lead to the creation of a ‘whole new realistic meat-like product segment’, according to Revo Foods.

“The aim is to significantly narrow the gap between animal products and plant-based or vegan alternatives, leading to wider adoption of meat alternatives in the market.”

Simsa told FoodNavigator that initially, product development is focused solely on seafood alternatives. “But in the future, we might explore other options as well.

“So far, we see seafood as the biggest growth opportunity given the limited options available and the small availability across different markets.”

For Mycorena’s part, the supplier has ‘always’ been interested in 3D printing for food, and suspected that creating a printable mycelium material would ‘open doors’ to creating ‘amazing, unique products’.

Indeed, compared to the more traditional production methods – such as extrusion or moulding – 3D printing can create ‘complex’ products with more realistic sensory properties and mouthfeel. This can eliminate the need for expensive tooling and can reduce storage space and time by being able to produce on-demand instead of batch-wise.

“With this technology, the possibilities for texture and form are on another level compared to current meat analogues, being restricted only by imagination, not processing methods,” said Mycorena CIO Paula Teixeira.