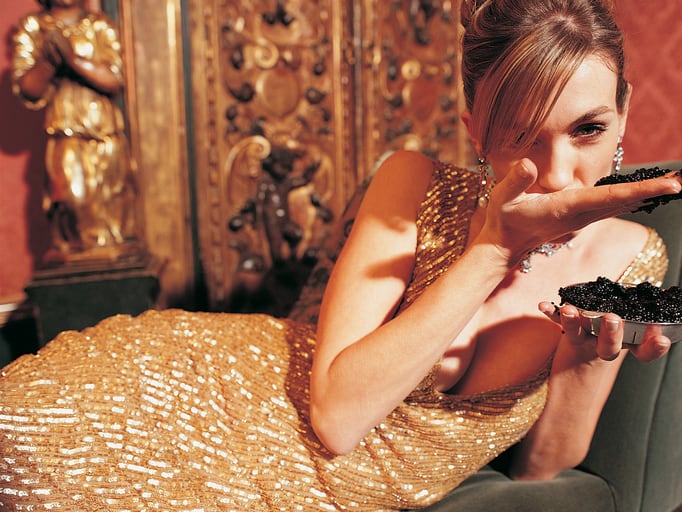

Pearlita Foods has set out to make the first cultivated oyster meat. Its mission is to “harvest the ocean's finest foods” and “revolutionize the way that people eat the sea's finest delicacies through ethical, clean and sustainable methods”. Pearlita aims to produce oysters with no reliance on the ocean or live animals, by using stem cells and bioreactors to produce cell-based oysters that have “rich flavour and substantial nutrition”.

Oysters used to be abundant around the world. However, the company, based in North Carlina in the US, claimed that today over 85% of wild oyster reefs have been lost globally. With ocean temperatures rising and contamination, the future of oyster farming is uncertain, the company warned.

Food security, safety and nutrition

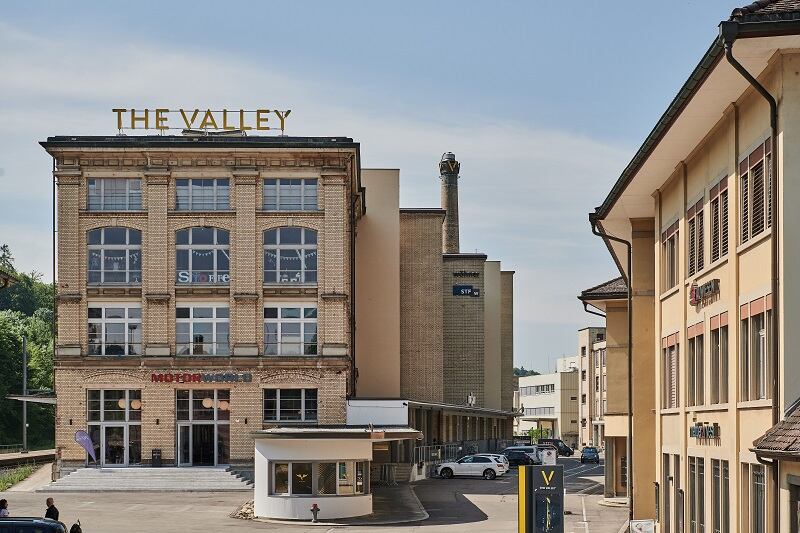

Speaking at Bühler Group’s Networking Days event at the supplier’s headquarters in Uzwil on June 27-28, Pearlita Founder CEO Nikita Michelsen, who is originally from Denmark, grew up in Sweden and moved to the US in 2011, explained cell-based technology allows for a safer and more accessible product.

"I grew up on the coast of Scandinavia where there's a lot of fresh seafood like eels, crayfish and oysters,” she said. “Today all these species are very difficult to come by. So for me, this not only solves food security it's also about making sure we have those culturally important traditions and delicacies that we grew up with. I want that for my future children.”

She added that oysters, at least based on anecdotal evidence from those living on the Scandinavian coast, are becoming increasingly contaminated. “They're not as fresh anymore. The tissue colour has changed over time from a much more translucent colour to a much cloudier colour.”

Contamination also brings food safety risks. On top of plastic pollution and heavy metals, rising temperatures, meanwhile “turn oysters into hotbeds for parasites and bacteria” that can harm humans.

Cell-based technology, thanks to its sterile environment, can solve this and more, she insisted. Using cell-based technology is very expensive, but oysters offer more of high value, low volume option, the CEO added.

Is there consumer demand for this type of product? Michleson estimated that current practices can only meet 30% of the demand for global molluscs and shellfish. “There is a lot of room for us to grow and tap into,” she said. “By using this type of technology we're really able to make something that is typically a coastal delicacy accessible to everyone, everywhere.”

Investors are pouring into cell-based

Pearlita Foods launched at the start of 2022 with funding from Sustainable Food Ventures and Big Idea Ventures' New Protein Fund and is continuing to develop its cell-based line.

Cell-based food is "bioidentical to the traditional product”, proclaimed Andrew Ive, CEO and founder of Big Idea Ventures, an early stage accelerator. “The technology is getting there very quickly,” he added. “The challenge we have is the regulatory environment. Governments are not keeping pace with where the technology is going.”

Ive elaborated on why his venture capital group is backing the quickly moving but nascent cell-based sector. “Big Idea Ventures has invested in over 130 companies in the food sector over the last eight years we're focussed on solving the world's greatest challenges -- in particular, climate change and sustainability -- by backing the world's best entrepreneurs, scientists and engineers,” he explained.

“We believe it's possible to create wealth for our investors by doing the right thing and by working with young companies that have global impact.” Corporations, meanwhile, are an “incredibly important part of the solution”, he added, noting, perhaps ominously: "If you're not part of food future as a corporation, you're going to part of food history. That's what it comes down to."

Partnerships are key to accelerating new tech solutions

Case in point, Bühler used the event to stress it is very much backing new technology as it aims to have solutions ready that reduce energy, waste, and water by 50% in the value chains of its customers by 2025.

At the Networking Days event, the Swiss supplier unveiled new partnerships in the plant protein, cell-based protein, biotechnology and circular economy sectors.

It announced the completion of the Cultured Hub near Zurich, a joint venture agreed by Swiss companies Givaudan, Bühler, and Migros in 2021. Equipped with a product development lab, cell culture and fermentation capabilities, the Cultured Hub aims to help start-ups to develop market-ready products, accelerating the journey to readily available, sustainable, healthy, and affordable meat alternatives. “We have a Managing Director in place and are on track to be helping companies scale from early 2023. The first companies are booking time and facilities,” said Ian Roberts, CTO at Bühler Group.

Bühler also announced the formation of a new joint venture with Austrian pharmaceutical and biotechnology company ZETA.

The new company, Eridia, will engineer food and feed biotechnology plants primarily in the fields of precision fermentation and cellular agriculture. Roberts said the 50/50 joint venture, will enable Bühler and ZETA to contribute further to the field of precision fermentation as well as to the newer field of cellular agriculture.

“Harnessing bioprocessing for the food and feed industry is not new, but it needs to be applied at scale,” he explained. “Technologies such as precision fermentation and cellular agriculture offer the potential to drastically reduce the land and CO2e footprints of food and feed production. This is a potential pathway to produce food and feed for a growing world population whilst respecting the limits of the planet.”

Are skills gaps a bottleneck?

But what skills gaps has Bühler identified that may impact its ultimate plan to provide more impact-reducing solutions?

"Clearly, there's massive training needed around understanding sustainability,” Roberts responded. “You need everybody to understand how solutions impact sustainability... this we've been doing a lot. There's obviously training of operators to ensure there are skills sets to operate lines efficiency and digital training. The biggest one I think is building the skill to partner. Partnership isn't easy and to be able to understand that you have to build win-win relationships where you share the proceeds and you grow a bigger pie that you can share amongst more people is a change of mindset and that's a new skill set as well.”