Fats can be categorised based on origin into three groups: animal-based, plant-based, or microbial fats.

The first two are well-known for their multiple uses in food, feed, and biofuels. Microbial fats, on the other hand, are a lesser-known alternative.

What are the challenges and opportunities in producing microbial fat for these three sectors?

How is microbial fat produced?

Microbial fat is, in essence, oil produced from microorganisms. These microorganisms could be yeast, microalgae, or different varieties of fungi or bacteria, explained Hannah Karlsson Potter, researcher at the Swedish University of Agricultural Sciences in Uppsala’s Department of Energy and Technology.

“If they are capable of accumulating 20% of their cell weight as fat, they are called oleaginous microorganisms,” said the researcher at a recent TABLE event coordinated by the University of Oxford, the Swedish University of Agricultural Sciences, and Wageningen University & Research.

To focus specifically on oleaginous yeast, the microorganisms require carbohydrates – or sugars – to grow. Potential oleaginous yeast feedstocks could include crop residues or forest residues, such as wood.

Yeast can also use organic acids and aromatic compounds, released from degradation of hemicellulose and lignin, respectively, as carbon sources to accumulate lipids, we were told.

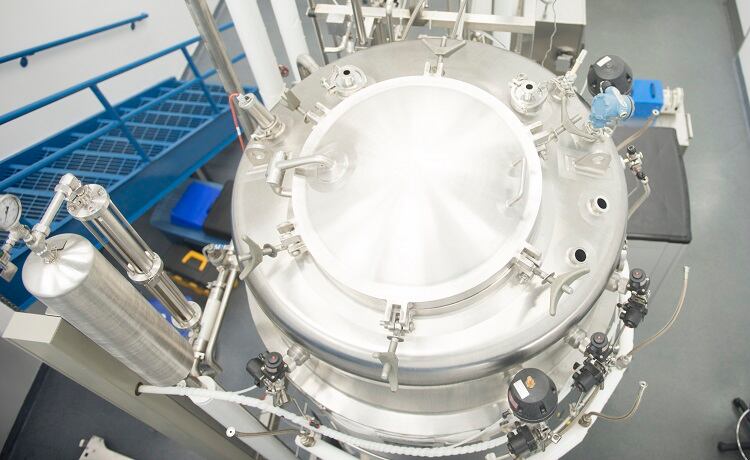

“Most oleaginous yeast needs sugars to grow…but the feedstock needs to be pre-treated so that the sugars are in a solution…Then you grow the yeast in tanks for around three to five days. They’re fast-growing, which is one of the advantages of yeast compared to, for example, algae.”

As a general rule, yeast accumulate fat in ‘nutrient limited’ conditions, meaning that while a high sugar content is required, nitrogen content should be low. That fat will ‘bubble inside’ the yeast cell, before the cell wall is broken and the oil released.

The process produces a side-stream in the form of a ‘yeast biomass by-product’, which the researcher explained contains ‘a little bit’ of protein. “It could potentially be used for animal feed,” we were told.

Production potential and sustainability challenges

In theory, oleaginous yeast has the potential to yield 0.32g lipids per gram of glucose. In practice, that yield is around 0.2g of lipids per gram of sugar, because the yeast requires the sugar for other functions, such as building its cell wall.

This means that one tonne of dry matter lignocellulose biomass, such as straw, could produce approximately 124kg of oil. Energy forest crops have a high yield, with 104kg of oil produced per tonne of dry matter.

How does this compare to vegetable oils? “For rapeseed in Sweden, for example, you would have a yield of approximately 1.5 tonnes of oil in winter rapeseed for around 1,000 of dry matter,” explained Karlsson Potter.

Palm oil, too, hits production out of the park: the world’s most consumed vegetable oil has an impressive yield of around four tonnes of oil per hectare. Yet that high yield comes at a cost: palm oil production is a major driver of deforestation in some of the most biodiverse forests on the planet.

Oleaginous yeast production does come with some of its own sustainability challenges, the researcher explained. Firstly, sustainable production is dependent on the biomass used.

When using crop residues, harvesting must be limited to maintain soil’s organic carbon. “If you look at crop residues, this has been questioned a lot due to the risk of decreasing soil of any carbon,” we were told.

Another sustainability challenge lies in the amount of energy required to release sugars from the biomass. “When you want to free the sugars, some say that requires a lot of energy – so that needs to be efficient,” said Karlsson Potter.

“But also, the process is aerobic, which means you need to pump air into the fermentation tanks and that also requires a lot of energy, So that needs to be efficiently done for the process to be beneficial.”

The researcher also stressed there is a need to develop a ‘good’ extraction method for the lipids that does not involve hexane – a ‘problematic’ substance in many ways. Chronic long-term exposure to hexane in air is associated with polyneuropathy in humans.

“And from an overall, systems perspective, it’s good to find a use for the protein-rich by-products that could benefit [other technologies]. It’s also important from an economic perspective.”

Oleaginous yeast for food, feed, and biofuel?

The fatty acid composition of oleaginous yeast oil varies according to the strain and carbon source. Other factors that can influence its composition include growing conditions, such as the temperature of the bioreactor.

But in general, many of the yeasts can produce oils with similar properties to vegetable oils.

As it stands, yeast oil is predominantly used in animal feed, and more specifically, as an ingredient in fish feed.

It has had limited use as food for human consumption, except for under exceptional circumstances: yeast lipid was used to replace vegetable oil during both First and Second World Wars in Germany.

Of course, using microorganisms to produce food is not anything knew. “We are using baker’s yeast for a lot of different purposes already, such as baking bread, making beer, and for bioethanol production,” explained the researcher.

In Europe, many oleaginous yeast strains are not yet approved for commercialisation as a dietary fat. Are there food safety issues industry should be aware of before producing it as such?

According to Karlsson Potter, it depends on the substrate used to grow the cells. “It there is anything in the substrate that we don’t want, [that could be a concern].” Data from SLU’s tests, however, suggest concentration of organic pollutants in yeast oil is ‘far below’ the limits set by European legislation.

Another factor is the solvent used, and ensuring it’s approved for human consumption. And of course, whether the microorganism in question has been genetically modified.

“In some regions of the world, it [depends] if the yeast is a genetically modified organism of not. Some yeasts are not genetically modified, but there is work being done to modify them also.”

The researcher stressed that for the moment, she is not working with genetically modified organisms: “The yeasts are accumulating high amounts of lipids without any molecular manipulation.”

Oleaginous yeast also has the potential to replace at least some of the palm oil used in biofuels, suggested the researcher.

A sustainable alternative to palm and coconut oil?

Food tech start-ups are catching on to the potential of oleaginous yeast as a fat ingredient in food formulation.

Swiss company Cultivated Biosciences, for example, is feeding yeast with agricultural side-streams to make a ‘high fat cream’ alternative it says can be used in a ‘very similar way’ to its conventional counterpart.

Using yeast oil in this way comes with both nutritional and sustainability benefits, Cultivated Biosciences CEO Tomas Turner told FoodNavigator in an interview last year.

“We have no cholesterol in our fats, and we can work and tune the saturated level depending on the product. So in some products, we will be able to have a lower saturated level compared to animal-based dairy, as well as coconut and palm oil alternatives.”

From a sustainability standpoint, an easy estimate of a one-to-one comparison with conventional cream suggested Cultivated Biosciences’ alternative produced 70-80 times fewer CO2 emissions. The start-up’s ingredient also had a lower water footprint.

Turner is working on several yeast species and confirmed the start-up’s fat ingredient will be classified as a novel food. As such, it will need to undergo a more stringent regulatory approval process.