Afyren, a sustainable chemistry company founded in 2012, has announced a distribution deal for the key European flavours and fragrances market with Ennolys by Lesaffre, just one month after raising €70.4 million in its IPO.

The agreement sees Ennolys by Lesaffre – a business that already offers a wide range of natural flavour molecules such as vanillin – secure exclusive distribution of the Afyren Neoxy range of seven biobased acids. The ingredient supplier will market Afyren Neoxy products to its existing customer portfolio, which includes a ‘large number of players’ in the European flavours and fragrances market.

"This distribution agreement is an important milestone to give the flavour and fragrance market easy access to Afyren's portfolio of natural acids. This approach combines Afyren's innovative products with the Ennolys by Lesaffre know-how and network to distribute in the European flavour and fragrance market," Afryen CEO Nicolas Sordet told FoodNavigator.

A ‘unique’ circular technology

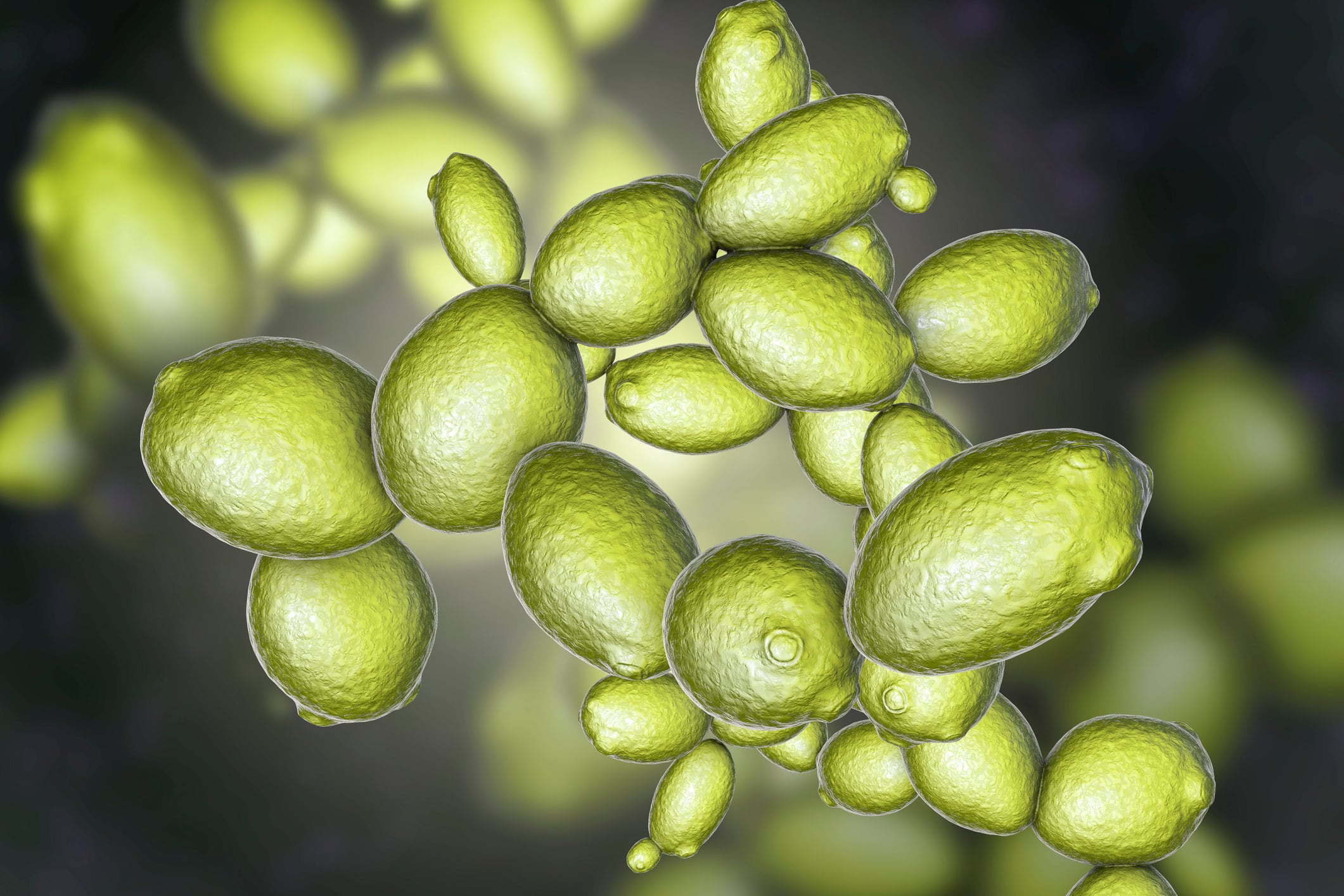

Afyren has developed a technology to produce biomolecules derived from the reuse of non-food biomass, such as sugar beet. The company’s ‘unique’ fermentation process is non-GMO, 'close to zero-waste' and has a low carbon footprint.

“The process is based on anaerobic fermentation using natural microorganisms. The company's near to zero-waste process does not need any complex chemical components to produce a reaction as it is biomimetic: we reproduce anaerobic fermentation that is natural and uses microorganisms that are not genetically modified,” Nicolas Sordet revealed.

“What is unique in our technology is that we are able to produce seven organic acids at the same time; they will be produced using renewable agricultural co-products and the process of fermentation is biomimetic. Remarkably, the only by-product the process produces gets returned to the agricultural sector as fertilizer that can be used in organic farming, thanks to our agreement with Terrial.”

This innovation represents a ‘serious alternative’ to petro-based products for companies that want to lean into a production chain that is both natural and sustainable, we were told.

“This circular process using renewable resources enables us to reduce carbon emissions and drastically lower the environmental impact compared with equivalent petro-based products. By using locally supplied renewable raw materials (which sequester CO2 during their growth) in a low energy consuming process, the carbon footprint of the organic acids Afyren will sell is 81% lower than existing petro-based equivalents, according to a life cycle analysis.

Developing a circular model

The food sector needs to become more efficient in its use of resources if it is to meet rising demand from a global population within finite planetary boundaries.

Afyren was founded to meet the growing need of industries to reduce the use of petroleum derivatives in their production chain. The company’s approach is ‘firmly grounded’ in the circular economy using technologies that are the result of a decade’s worth of research and are patented worldwide.

The company’s fermentation technology can work with different feedstocks and the group made the choice to work with agro-industry co-products to enter into a ‘complete circular bioeconomy model’. Currently, the group uses sugar beet co-products – but there is potential to expand, FoodNavigator was told.

“Our raw materials are sugar beet co-products that do not compete with the food chain and come from a radius of a few hundred kilometres around our Afyren Neoxy factory in the North East of France. We have signed a long-term agreement with Südzucker, the number one European sugar producer, to secure the supply of these co-products, which would have little value if we did not use them in our production process,” Sordet elaborated.

“Our technology allows us to use a large variety of raw materials. One could think of brewery production residues, other types of crops (corn, etc). As one of our goals is to have a low impact on the environment and develop a circular business model, we will select our raw materials based on the specificities of the regions that we will choose for our next factories.”

Sordet believes that these kinds of approaches and technologies will be essential to develop a circular economy and shift away from a reliance on petro-based products.

“Fermentation is one pillar to achieve a transition from a linear extractive petro-sourced model to a regenerative circular model, and there are other choices (water recycling system, local renewable material) that are also essential.”

Flavours and fragrances: A market with ‘great potential’

The tie-up aims to accelerate Afryen’s penetration in the European flavours and fragrances market, which the company noted is experiencing ‘sustained growth’. The company sees ‘strong’ demand in the sector for natural, locally manufactured aromatic molecules and believes this presents opportunities for ‘attractive commercial positioning’.

From a functional perspective, Sordet noted that the ingredients perform on a par with conventional alternatives – but with some added benefits. “The products offer equal performance compared to conventionally produced alternatives with the additional benefits of being natural and more than 80% reduced carbon footprint versus conventional offering. Functionally, the flavours can be used to obtain, for example, cheesy, buttery or vinegar like notes in food and food preparations.”

These attributes are important to companies operating within the flavours and fragrances space, Afyren believes, noting that the sector has been a ‘trailblazer’ in the adoption of natural ingredients in their manufacturing processes.

“Afyren is taking a position in a growing market where sustainable development issues have become essential, and where it will be able to make the most of the innovative, natural and low-carbon qualities of its products. Everything is now in place for Afyren’s biobased solutions to become a must-have for leading perfumers and flavourists,” the chief executive claimed.