Sophie’s BioNutrients is developing a range of microalgae-based protein flours for plant-based meat and alt dairy categories.

Aside from being high in protein, microalgae are a source of carbohydrates, polyunsaturated fatty acids, iron and B vitamins.

However, at this year’s Food Ingredients Europe (FiE) event in Frankfurt, Sophie’s BioNutrients CEO and co-founder Eugene Wang did not play up its health benefits. “We all know microalgae is nutritious,” he told delegates.

Rather, the start-up is setting itself apart in terms of sustainability and functionality: it embraces the circular economy and according to Wang, its first protein powder product is ‘good enough for any kind of plant-based dairy application’.

Protein with ‘wonderful colour and flavour’

Sophie’s BioNutrients was established in 2017 by co-founders Wang and CTO Kirin Tsuei, after Wang learnt of his daughter Sophie’s allergy to shellfish. Their mission was to create a high-quality, nutritious, and importantly, non-allergenic, protein alternative.

Observing the meat-free trend, the founders noted it was being dominated by plant-based alternatives. Wang takes issue with many of these products, stressing some are allergenic, lacking in nutrients and variety, challenging to scale and expensive.

“The question is: Is the plant-based protein we’re promoting to the world really the silver bullet we’re looking for? We do not think so.”

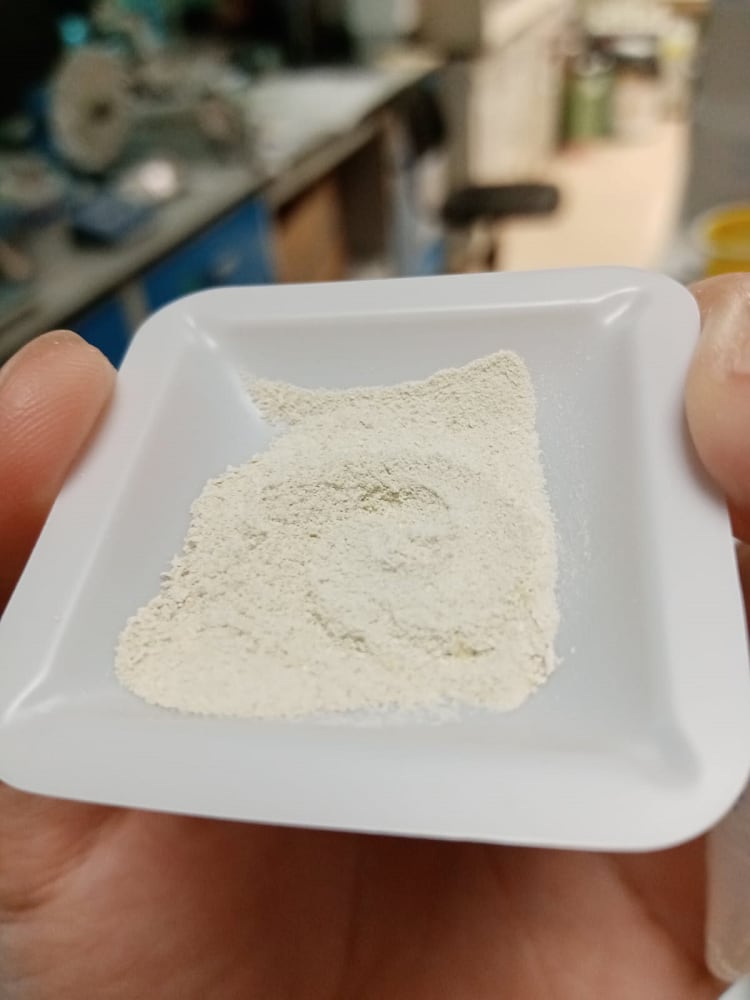

Sophie’s BioNutrients’ solution lies in microalgae, which it ferments in bioreactors before isolating its proteins and transforming it into a powder for food formulation.

To kickstart production, the team underwent a thorough strain selection process. “We’ve been through, by now, over 1,200 different species of microalgae,” said Wang. “We finally found about four strains that we can grow, in the dark, in fermentation…that are sturdy enough to be fed with all kinds of industrial waste.”

The CEO continued: “After our protein isolation process, it has a wonderful colour, a wonderful flavour…a protein flour that in the future can be priced competitively.”

Circular economy

An undoubtedly attractive quality of microalgae for Sophie’s BioNutrients is its sustainability profile compared to animal- or even some plant-based alternatives.

At FiE, Wang described the production process as ‘maximum protein with minimum footprint’.

“The beauty of [leveraging] fermentation, is that everything is a lot less,” he explained, comparing land-use, time, water, and energy-use with animal protein production, as well as pea and soy, on a per-unit basis. Indeed, its microalgae-based protein powder can be produced in just three days, and producing one ton uses just 0.02 hectares of space.

“But more importantly, with fermentation, you don’t have …harmful herbicides, fertilisers, antibiotics or hormones.”

The other strong sustainability angle is Sophie BioNutrients’ commitment to the circular economy. The start-up is feeding its microalgae strains with side streams from the food and beverage industry.

Three primary side streams are being upcycled for this purpose: brewer’s spent grains, okara (soybean pulp), and molasses from sugar refineries.

Partaking in the circular economy also yields financial benefits, the CEO explained. “It turns out it’s a wonderful idea, not only does it create a circular economy, but it also helps reduce our production costs.”

Commercialisation strategy

Sophie’s BioNutrients is targeting manufacturers of plant-based meat and dairy alternatives with a range of protein flours.

Founded in Singapore, the start-up is making plans to move ‘a lot’ of its operations to Europe, revealed the CEO: “My guys are planning to relocate from Singapore to Amsterdam at the moment.”

Wang continued: “Quite frankly, we see the future of alternative protein, especially microalgae protein, right here in Europe.

“So we want to make Europe our main customer base for the sale of our protein flour.”

The start-up achieved its first Proof of Concept (POC) in a 10L bioreactor in 2018. Last year, it successfully upscaled to 10,000L.

It expects its first protein flour, which can be used for solubility, viscosity and foaming in milk, cheese and protein drink products, to reach the market in 2021-22. Its second protein flour has a similar timeline but has emulsification properties for meat alternatives.

Sophie BioNutrients plans to market at least another three protein flour products within the next three years.

Wang said he was convinced of the market opportunity within the protein alternatives space. “The market opportunity is very real,” he told delegates.

According to a 2021 study by BCG and Blue Horizon Corporation, the market for alternative meat, eggs, dairy, and seafood products is set to reach at least $290m by 2035.

However, even more relevant for Sophie’s BioNutrients, the same study predicts alternative proteins made from microorganisms like fungi, yeasts, and single-celled algae to reach taste, texture and price parity with conventional animal proteins by 2025.

“[The research] basically says that by the year 2035, people are going to consume a lot of tonnage of microorganism-based protein. And that translates into a huge among of dollars that in the future we can go after,” said Wang.