It has been widely reported that around one-third of all the food produced globally is wasted.

René Floris, NIZO Food Research Division Manager and member of the FoodNavigator expert advisory panel, asks Peter de Jong, NIZO’s Principal Scientist in food processing, professor of dairy process technology at Van Hall Larenstein University of Applied Sciences and director of New Technology Development for Food at the Institute for Sustainable Process Technology (ISPT), what role food fractionation and the smarter use of raw materials can play in tackling food waste and boosting sustainability.

René Floris: What is food fractionation?

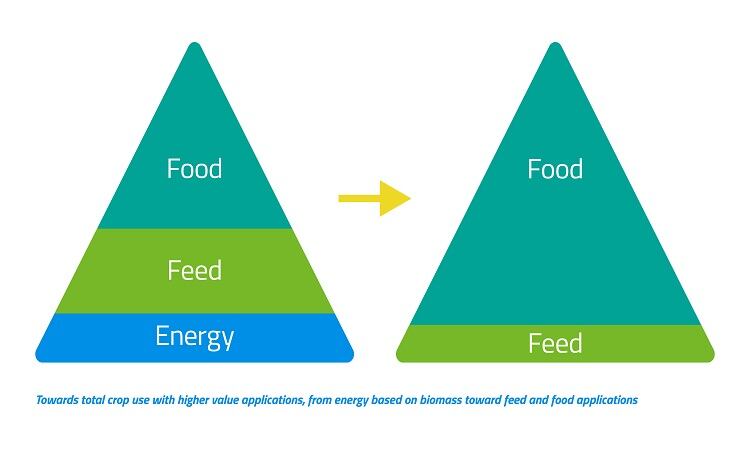

Peter de Jong: The modern food industry has developed to manufacture products based on highly purified ingredients. For example, sugar beet is processed into pure sugar and legumes into 80-90% protein powders that are then used to create the products we see in our supermarkets. But this extreme purification requires a lot of energy and leads to a great deal of waste and overproduction: currently only about 65% of a sugar beet makes it into food applications. But the food industry is increasingly aware of the need to reduce its environmental footprint. And that will require novel approaches.

One such idea is to move away from extreme purification of raw materials. What if we instead split raw materials into fractions that are rich in a particular nutrient but still retain some of the matrix of the raw material from which it is derived? So, legumes could be processed to fractions that are 50% or 60% protein but still contain, perhaps, sugars, starches, fats, etc. This could increase the proportion of the raw material that makes it into food applications, saving a great deal of energy.

RF: How well established in the industry is food fractionation?

PdJ: The industry is well aware of the need to reduce waste and improve sustainability in food production. As a result, there have been efforts to deploy fractionation in most countries around the world. But to date, these efforts have usually focused on valorising waste by generating additional revenue from side streams. A typical example would be to extract the sugar from sugar beet conventionally and then look to fractionate whatever remains into usable ingredients.

However, to achieve the next step in sustainability, the industry will need new ways of thinking. This becomes especially important in light of the ongoing protein transition. With dairy, the proteins are easily accessible, and it is really just a question of making the food safe. But plant-based proteins need to be extracted from the relevant plants, which requires much more processing. And that processing takes energy.

So we need a more comprehensive approach to fractionation. That means thinking about what we can get from different types of plants – from sugar beet and legumes to potatoes, onions, oil-containing seeds and green vegetables – and then fractionating the whole plant.

RF: What are the key questions for sustainable fractionation?

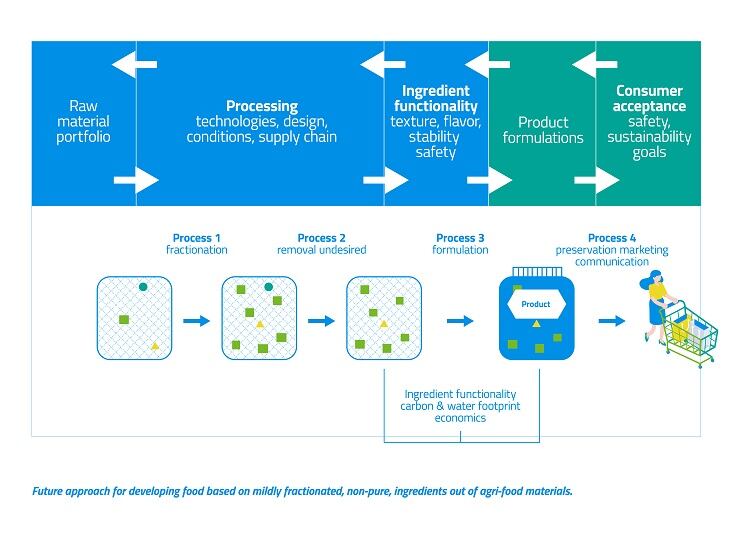

PdJ: There are two big areas the industry needs to address. Firstly, can we still produce high-quality food products that are attractive to modern consumers from less pure ingredients? Secondly, how do we extract the fractions to create ingredients with the right functionality?

These two areas are actually closely intertwined. For example, maybe the fractions don’t need to match the functionality of today’s familiar ingredients so long as the different fractions can be combined into a product with the right characteristics. That could open up the possibility of a fraction replacing multiple ingredients and supplying multiple functionalities. You could imagine a sugar-rich fraction from sugar beet providing both sweetness and colour for a cola drink for example.

However, because they are less pure, fractions are likely to be more variable in composition which could make it difficult to maintain consistency in end products. Is that a problem? Right now, we don’t know. It is open whether consumers will accept variation in processed foods.

RF: Are new process technologies needed to extract fractions from whole plants?

PdJ: That is something that the industry is currently exploring. However, there are many existing processing technologies that could be deployed, possibly with some adaptation, for use in fractionation. For example, we can use various dry separation techniques to remove leaves and stems from plants, while spray dryers, which are more familiar for processing particle-free liquids, could be repurposed to dry leaves and solid raw materials.

One thing that is clear though is that we will need to revisit the whole process design for these techniques. Take membrane separation. This is a long-term emerging technology for separating food components and a promising candidate for use in sustainable fractionation. But if we want to use it for creating less-processed, less-purified fractions there is a greater risk of fouling, and we may need to develop new membrane materials and use different process configurations.

RF: Given the importance of sustainable fractionation, how does the industry go about developing it?

PdJ: Sustainable fractionation can’t be developed by one company alone. It will take the whole supply chain. As I said, the key questions of extracting fractions and using them are intertwined and so success depends on bringing together people who think about process technologies and people who develop products. You also need people that can develop the right business cases as well as marketing experts to explore and build consumer acceptance of products created from fractions. Without close iterative loops between these groups, we are unlikely to achieve a viable fractionation model.

There are initiatives throughout the industry to develop sustainable fractionation and the technologies that will make it possible. In my joint role with NIZO and the ISPT, I am personally involved in one such project which brings together industrial partners from across the supply chain to develop novel processing routes that could be employed for sustainable fractionation of crop and dairy sources.

Collaborations of this kind are critical to developing a more sustainable food product supply chain. It is hoped that they could not only reduce waste but also cut energy consumption in food processing by 50% as well as reducing the water footprint of the industry.

Next month, we will return to the topic of the health benefits of food and ask how food ingredients can modulate the immune system.