Start-up Koa is repurposing the pulp and juice of the cocoa fruit for food and drink manufacturers.

By bringing a ‘previously unknown’ taste to the European market, the Swiss-Ghanaian operation says it is ‘opening up new possibilities’ for food and beverage, as well as for gastronomy.

However, Koa is also focusing on making social impact at the source: in reducing food waste, the start-up is providing cocoa smallholders with an additional income.

By making use of the so-far-lost cocoa pulp, Koa aims to boost the local economy in rural Ghana, start-up co-founder and managing director Anian Schreiber told FoodNavigator.

“Processing the fresh pulp allows us to pay cocoa farmers an additional income and at the same time, we generate jobs for young locals from the communities.”

Post-harvest innovation

Ghana is the world’s second largest cocoa growing region, with more than 800,000 smallholders cultivating cocoa on remote plantations with an average size of two-hectares.

As ‘most’ cocoa farmers there ‘live in poverty’ – which is the root cause of child labour and deforestation, amongst other violations – the Ghanaian cocoa sector caught Schreiber and his co-founders’ eye ‘right away’, he explained.

Koa is focused on the post-harvest process of cocoa fruit production, which has largely remained unchanged ‘for centuries’. The start-up puts this lack of technological development down to the difficulty of accessing the cultivation areas.

“This is why, until now, only the beans could be processed,” explained Schreiber. “The beans only make up a fraction of the fruit – around 25% in our area.”

Koa aims to ‘smoothly integrate’ its new process into the local and traditional cocoa harvesting setting. Kickstarting in 2017, today the start-up cooperates with more than 1600 smallholders and has 35 team members in Ghana’s Assin Akrofuom district. “Our first factory has a capacity of 250t and we’re currently building our second.”

Koa ‘works closely’ with cocoa smallholders to extract the juice and pulp with a mobile and solar-powered processing unit located ‘right next to the cocoa farms’. “The pulp is gently processed, while we leave enough pulp on the beans to ensure that the fermentation of the beans still naturally happens,” the managing director explained.

After processing, the beans are returned to their owners, who then continue with the traditional processing of the beans.

The entire process is digitally traceable, Schreiber continued. Koa is currently working on blockchain integration to ensure full transparency.

“In a nutshell, our goal is to empower rural communities in West Africa to create significant added value to the global food system for unique taste experiences and positive impact.”

Cocoa juice and pulp for food applications

Koa has three products for the food and beverage industry. Koa Pure is made from cocoa fruit juice, Koa Concentrate is made from concentrated cocoa fruit juice, and Koa Powder if processed from dried cocoa pulp.

The products can act as a natural sweetener, or can be used to impart ‘new flavour experiences’ in food applications, explained Schreiber. “The 100% natural ingredients are suitable for vegans, have no added sugar, are non-GMO and are a natural source of polyphenols and potassium.

“Koa opens up new opportunities for chocolate, bakery, and ice cream products, as well as beverages.”

Another way food and beverage makers can benefit from using Koa’s products is via sustainability messaging, suggested the managing director. “We enable brands to communicate the story behind the product and trace the ingredient back to its origin.

“We call it ‘Connect & Care’: connecting the brand and the consumer with the producer through digitisation.

“As a result, the consumers know they have done something good which will double their enjoyment – according to the principle ‘good for me, good for the planet’.”

Cocoa fruit sorbet and 100% cocoa fruit chocolate

Koa has partnered with a number of food and beverage makers across Europe.

In Luxembourg, Oberweise is using Koa Pure and Koa Concentrate in several of its pastry creations, from croissants to truffles, cakes, and tarts. In the Netherlands, Kumasi is leveraging Koa Pure for its bottled beverages, as is Majus in Germany, and Urban Lemonade in Switzerland. Again, in Switzerland, Confiserie Sprüngli is developing various pralines with Koa Pure.

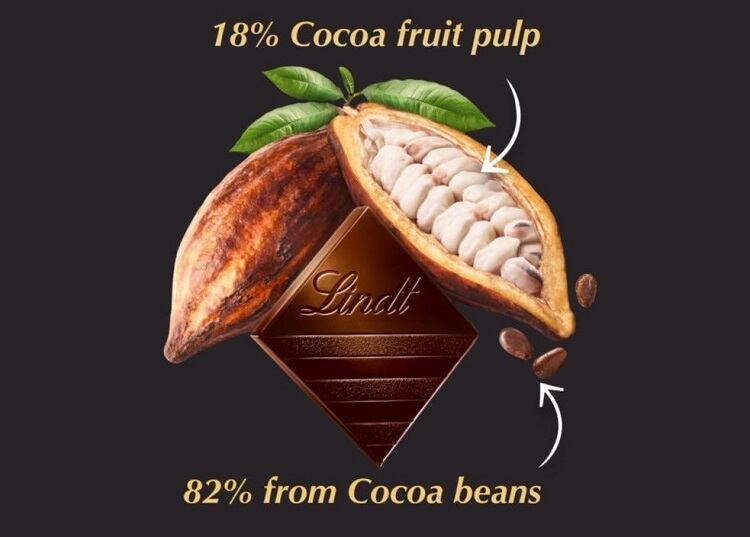

Swiss chocolatier Lindt has also partnered with Koa to produce a limited edition Excellence Cocoa Pure product. The tablet is made 100% from the cocoa fruit, without any other ingredients added – including refined sugar.

Specifically, the cocoa bean makes up 82% of the product, with 18% coming from the cocoa fruit pulp. The chocolate maker describes the taste as ‘initially sour and fruity’, followed by ‘an intense cocoa note’, with ‘subtle chocolate nuances’ in the end.

Most recently, Italian confectioner Venchi has also partnered with Koa to launch a cocoa fruit sorbet, as well as shake and praline offerings. The products are made with Koa Pure for Italian, German, and English markets.

"I am really glad we found a partner which is located directly at the cocoa farms and perfectly preserves this precious nectar," said Venchi director and innovation manager Giovanni Battista Mantelli.

"Thanks to this collaboration, we can present a world premiere of our Italian gelato made with cocoa pulp to discover the delicate fruity and refreshing taste which I tried for the first time when I visited the cocoa rainforest.”