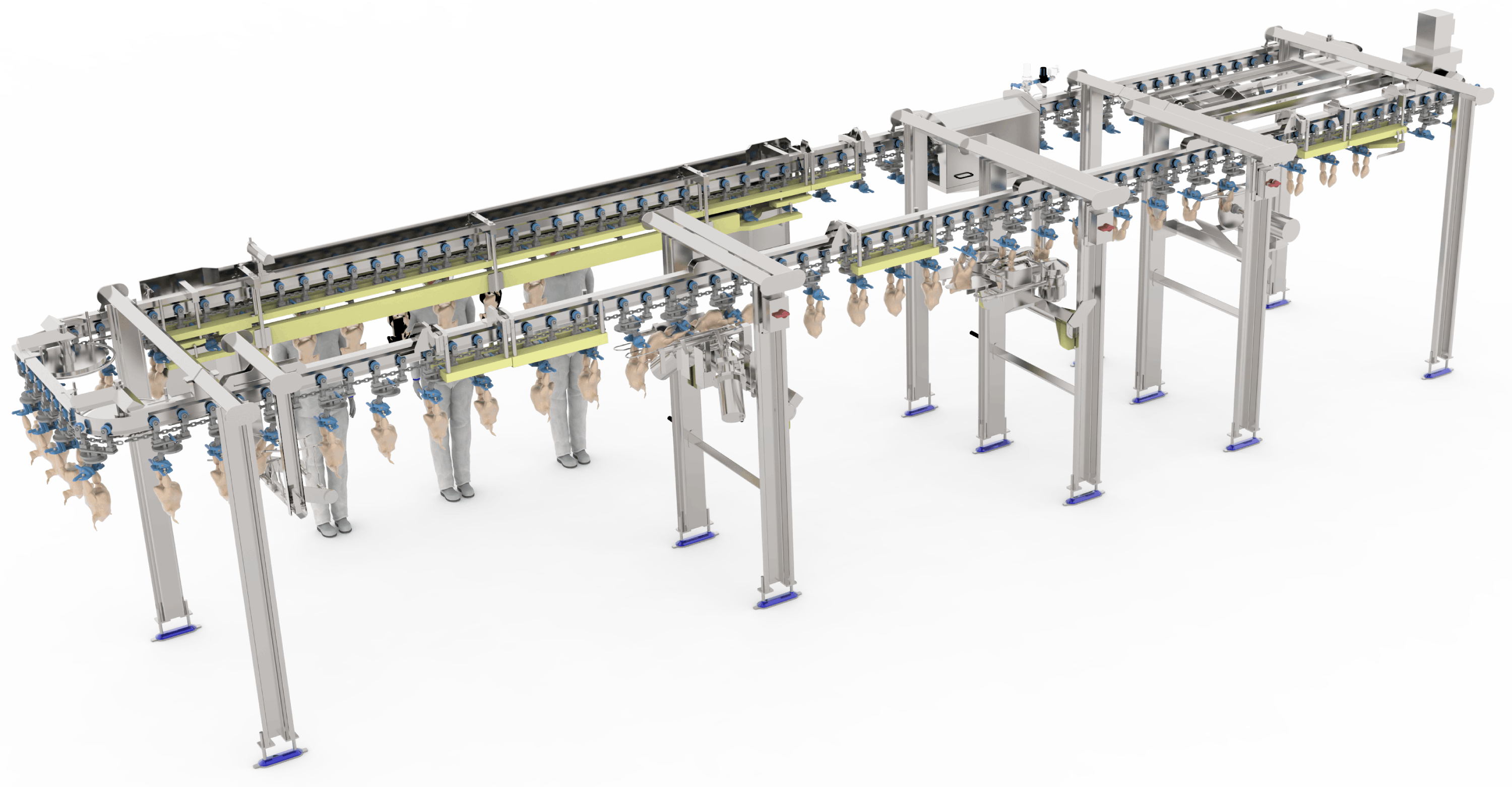

The ACM-NT Compact is a “slim fit” cut-up system that it claims is an easy-entry ticket to the world of automated cut-up.

A-grade cuts

“When a market, wherever in the world, gradually moves from whole bird to chicken parts, the volume of cut-up parts might be getting too large to handle manually, also in terms of labor availability. This is the perfect moment to take the first step in cut-up automation,” a spokesman for Marel said.

“Once the appropriate modules that comply with customers’ end products demands have been chosen, ACM-NT Compact does what it needs to do and fulfils all product needs.”

While performing the highest percentage of A-grade cuts in the industry, it can cut any specific chicken part customers ask for. This includes Quick Service Restaurant customers, who increasingly ask for chicken products accurately cut into bone-in pieces to compose multi-piece chicken buckets.

With the appropriate modules, ACM-NT Compact is able to produce these pieces, exactly according to the specifications of the QSR chain.

“In these pandemic times, processors around the world are facing a customer demand for larger numbers of cut-up poultry products in various mixes. ACM-NT Compact can be a very efficient system to fulfil this need for additional cut-up capacity and different pre-defined cuts. It can be installed quickly without adding complexity to the process or any layout changes needed,” said Harm ter Heerdt, regional sales director, Marel Poultry.

6,500 products per hour

ACM-NT Compact also takes into account the available space in a processing plant. The system offers three standardized overhead steel frames, all with a small footprint.

Shackling products and, if necessary, bypassing modules are simple manual processes. The maximum capacity depends on shackling speed, usually 6,500 products per hour.

If customer demand increases, upgrading is easy with gradual investments in time. The modular system can grow from straightforward production of chicken parts to an in-line cut-up solution, achieving multiple cuts intelligently and simultaneously without manual interference.