UK food producers are grappling with a skills shortage that threatens to leave produce ‘rotting in the fields’, according to some warnings.

An independent report commissioned by industry body English Apples and Pears highlights the scale of the problem for orchard-grown fruit alone.

The UK needs around 10,300 seasonal workers each year to manage and harvest an orchard-grown fruit crop of 300,000 tonnes, worth over £180m, according to the research conducted by consultancy Andersons Midlands. Without access to seasonal labourers from Europe, the consequence for the industry would be a “catastrophe”, English Apples and Pears chief executive Steven Munday warned.

“Until now the vast majority of our labour has come from Europe, but there are currently no post-Brexit guarantees that this will continue… Without this, the consequences for growers, consumers and the environment will be devastating,” he said.

The picture is no peachier for soft fruits. According to trade association British Summer Fruits, soft fruit growers employ around 29,000 seasonal workers a year, most of whom come from Europe.

A hard Brexit that restricted access to European fruit pickers would “crush” the British soft fruit industry, which is now worth £1.2bn. Prices of strawberries would rise by 30-50%, less soft fruit would be grown in the UK and the country would be more reliant on imports, British Summer Fruits predicted.

“This is as extreme as it gets. If we do not have the pickers, we do not have a soft fruit industry,” Laurence Olins, chairman of British Summer Fruits, stressed. “It is inconceivable that people who voted to leave the European Union wanted to destroy an iconic and incredibly competitive British horticulture industry… But if we cannot ensure access to the seasonal workers needed to produce soft fruit in Britain, that will be an unintended consequence of Brexit — along with soaring prices and increased reliance on imports.”

Seeking alternative ways of harvesting

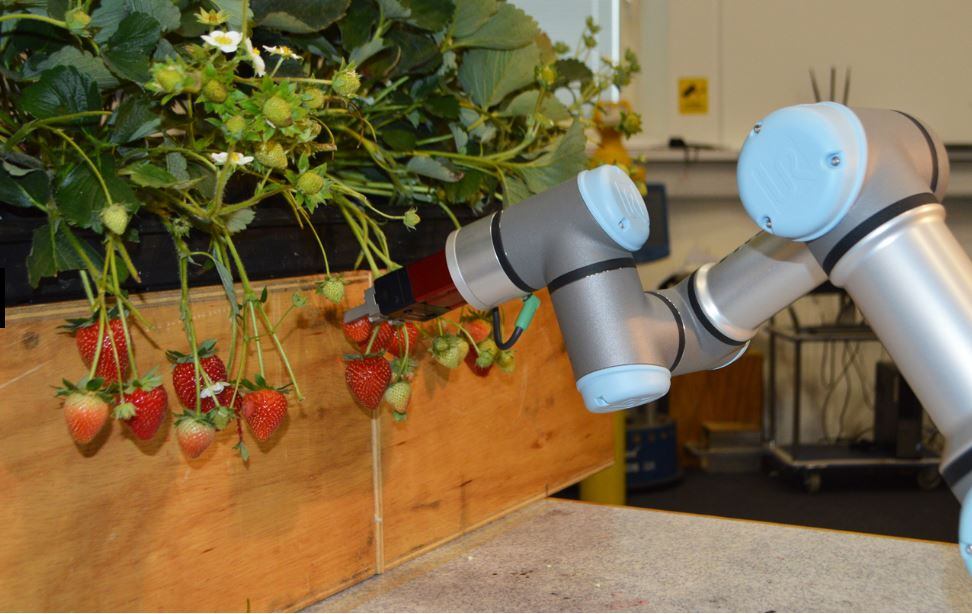

This challenge prompted jam maker Wilkin & Sons of Tiptree to look at alternative ways of harvesting its strawberry crop in conjunction with robotics experts at the University of Essex.

Currently one billion strawberries are picked by hand at Wilkin & Sons’ farm in Tiptree every year. The human fruit pickers have around half a second to check the strawberries for ripeness, disease and size. Automating this process using robotics is no small task.

“Fruit picking may seem a simple task but picking the fruit without touching the berry will be a challenge. We need to ensure that the fruit we grow always arrives with the customer in perfect condition,” said Andrey Ivanov, general manager of farms at Wilkin & Sons. “We are excited to be working with the University of Essex on this ground-breaking project.”

The research from Essex University, led by Dr Vishuu Mohan, from the School of Computer Science and Electronic Engineering, is part of a major project looking at how robots can work in natural, unstructured environments where they can pick, inspect and pack soft fruits.

Dr Mohan and the team at Essex are working to develop solutions that can deal with the complex variables robots would come into contact with in the field.

“No two berries are the same - they come in different shapes, sizes, order of ripeness and many are hidden in the foliage,” explained Dr Mohan. “Also the environment keeps changing constantly - sunny, windy, rainy - in contrast to a typical industrial environment. Hence, dextrous manipulation in unstructured environments is a big challenge for robotics today.

“Skilled humans find it effortless, but when we try to build a system which does the same thing it is a complex, integration of vision, touch, force and movement and on top of it the ability to learn and adapt - which is the only way to deal with any changing, unstructured environment,” added Dr Mohan.

To help the first part of the project to get robots to identify ripe fruit, scientists are working with a special variety of strawberry which has low hanging fruit. Work is underway to enable robots to select and pick them and a prototype should be available in few months time, the researchers revealed.

The research will then look at bi-manual robotic coordination to recreate how humans pick with two hands, active vision to find berries amongst foliage and learning to counteract changing environmental conditions.

Even as the technology advances, with the UK’s exit from the EU due to take place in March next year, it seems unlikely that fruit picking robots will be on the ground in time to make up for any manpower shortfall in the wake of Brexit. Nevertheless, agricultural automation could be part of a longer-term solution to a shortage of farm labourers.