The Pharos V8 is based on the company’s patented Pulse Controlled Amplification (PCA) technology.

Conventional PCR platforms rely on thermocyclers that the firm said can limit reaction speed.

PCA uses microcyclers in solution as miniature thermal hubs for the PCR reaction.

Laser PCR operates on the same principles as conventional nucleic acid amplification with PCR but uses nanomaterials to control temperature cycles at the nano scale.

Same conventional principles but faster

The company was founded in 2010 as a spin-off from the University of Munich and now employs 30 people.

Lars Ullerich, co-founder of GNA Biosolutions, said the principle of the technique is the same.

“It is still PCR we just make it faster. Customers who have existing assays can port them to our nanoparticle chemistry, they just need to add an anchor sequence to their primers,” he told us at Analytica 2018.

“The read out is conventional, it is fluorescent based detection so customers are used to the kind of curves that we are producing.”

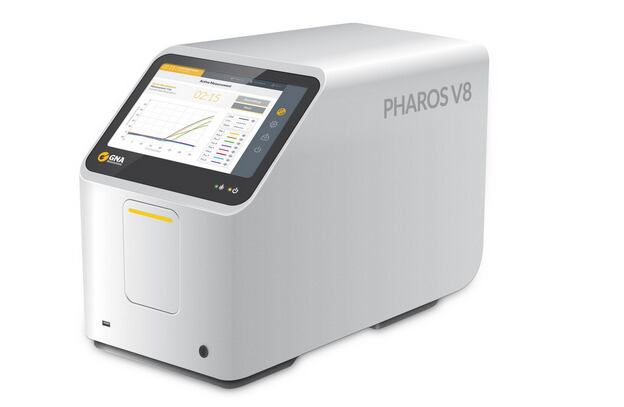

The first instrument is operated with a strip of eight tubes as efforts went into developing an ultra-fast system for detecting samples as they come in but future machines may have a larger capacity.

Ullerich said time to result is 10 minutes compared to 45-60 minutes in conventional PCR.

“In conventional PCR, heating and cooling is the most limiting factor and we have a totally different approach because we use microcyclers within the solution,” he said.

“In the case of our first instrument we use nanoparticles that get excited with a laser, these nanoparticles heat up instantaneously and as soon as the laser is turned off they cool down.

“Therefore we get rather instantaneous heating and cooling ramps and this accelerates the whole amplification process necessary for performing PCR and detecting minute target DNA of pathogens in your sample. We coupled this ultra-fast amplification technology with a conventional fluorescent read out as customers are used to in real time PCR.”

Exploring market opportunities

Anastasia Liapis, market development manager, said compared to conventional PCR the heating and cooling ramps are much faster.

“So that makes it possible for our cycles to be faster and the reaction to proceed at the speed it does. Our system maintains high sensitivity at large reaction volumes so there is some potential to dilute out inhibitors by diluting the samples,” she said.

“It is hard to change processes and one component of the process. Which is why it is easy to do, that has been a big focus of our development efforts to make it as easy as possible for the end users. That is the activation barrier many times, if they can’t do it easily it probably is not going to happen.

“For us [food and beverage] is a huge market but for the industry the combination of this level of sensitivity with the speed is powerful. If you have things that are perishable you need to have a quick answer.”

Potential for food safety

The company developed the V8 in two years starting from the base technology and prototype into a full product.

It is also implementing Laser PCR in an integrated sample-preparation system as part of a consortium focused on MRSA detection (KAREL).

Ullerich said for quality control purposes the faster the system and the nearer it is to the processes the better it is for quality assurance and contamination control.

“As we are a small company we are open for development partnerships to get the technology adapted for different needs and industries,” he said.

“We think water testing, food safety, quality assurance and contamination control are interesting fields but we need partners to get into them and develop what is needed at the production plant. The food industry is quite closed, it is hard to get in. There are some big and many small players and you need an entry point.

“We believe to be successful, to bring molecular detection near the point of need, we need to fulfil three aspects. Speed, ease of use and be affordable.”