Ron Stakland, also VP business development at Global ID Group, said globalization of ingredient sourcing has made it more challenging than ever to assess the chemical, biological and physical risks in the supply chain.

“Almost everybody has extremely globalised supply chains now, the material passes through many different hands and there is all kinds of opportunities for contamination, mislabelling and adulteration to happen from the time it leaves the field to the time it gets to your processing plant, so having visibility is very challenging,” he told FoodQualityNews.

“I sometimes tell people subscribing to HorizonScan basically means you are going to increase your QA department by several thousands of people because now all these inspectors that work for the FDA, or CFIA, or Japanese Ministry of Health or one of the EU countries, in a sense they are now working for you.

“Because when they find a problem and publish a notice it goes into HorizonScan and you have it typically within 24-48 hours of that report being made publically available to anyone. They recognise to try and replicate this they would have to hire a huge number of people, knowledgeable scientists and here they have it at their fingertips.”

Practical problem of managing risk

The web-based service was created and is operated by Fera and Global ID Group is the exclusive distributor for North America, Germany and Brazil.

It can be purchased on an annual subscription basis and pricing depends on how many user licences a company wants.

A ratings system for highlights is either red, yellow or green depending on the urgency.

Stakland said one of the things that had surprised him most since demoing the service was how relatively little companies were doing to get a handle on risks and manage them.

“Even some very large companies had never seen anything like HorizonScan and were putting multiple people doing Google searches, RASFF portal, FDA and so forth but the scope of information from HorizonScan is multiple from what even the best companies are doing manually. It’s almost a dirty little secret in the industry how little meaningful supply chain management is going on.

“The point of the FSMA is a paradigm shift trying to move the US food market away from reacting to events with a good recall plan and instead getting proactive, predictive and pre-emptive about how they manage risk. The problem is they are legally required to do this but a lot of people are scratching their heads saying how do we go about it without having to hire an entire research staff.”

At the moment companies concerned about the safety of their supply chain can get a free ‘Ingredient Risk Assessment’ using HorizonScan.

Stakland said it is a near perfect solution for some of the requirements in the FSMA.

“[The free ingredient risk assessment] is a way for us to give people a chance to get a taste of what HorizonScan can do,” he said.

“We schedule a time, we go online with them into the database and we do searches on one or two food commodities that they pick. It is actually really hard to find information about these different food commodities, especially if you are trying to find country specific information that is current and reliable.

“You could Google search all day but from our perspective you would only be scratching the surface of all the information that is available. You can do in HorizonScan in less than a minute what would probably take a person weeks to do manually if they didn’t have access to a technology like this.”

Risk by product and region

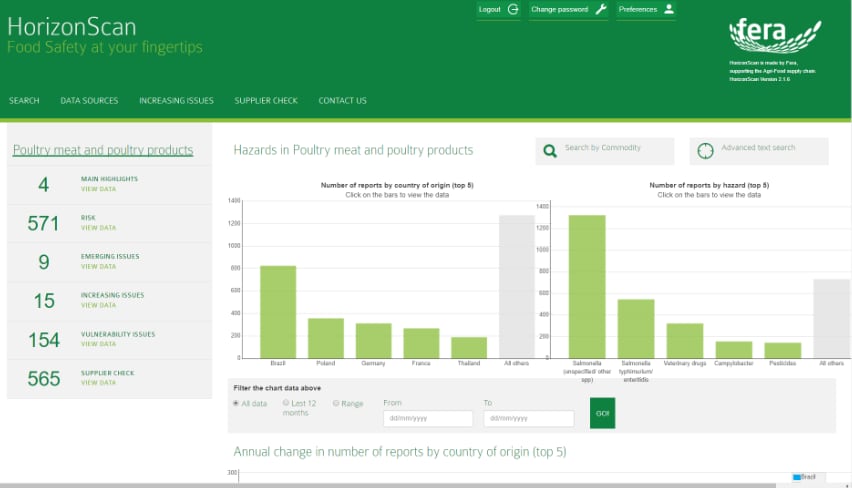

HorizonScan is a database of over 105,000 records and each is a report about some sort of safety or quality incident involving a food material somewhere in the world. It covers food that originates from over 180 countries.

It pulls in information from over 100 different inspection agencies, industry publications and reliable sources worldwide with updates twice a day and has links so subscribers can view the original source and language of alerts.

Daily or weekly updates can be customised to keep up to date and users can search by commodity, country of origin, type of hazard, supplier and date of event.

Searches can be done on a specific food commodity, said Stakland.

“Lets say that I was a food manufacturer and one of the things I used in my product was the spice black pepper,” he said.

“If I am sourcing that pepper from India, Brazil and Vietnam I can go into the database and I can do a search on pepper and I can get very specific and view what are the kinds of hazards that have been reported with regard to pepper from India and how is that different from pepper from Vietnam or Brazil.

“I might see in one country we have a relatively high risk of Salmonella contamination and in another there may be a lower risk of that but a higher risk of pesticide residues. With this knowledge a quality manager can get very specific about what kinds of hazards they are going to require their supplier to manage and test for and certify as being free from.

“The food company can structure its own validation program, testing and sampling program to focus on those issues that are most likely to be the problem and also to make sure they are not wasting money testing and controlling issues that are not being reported anywhere around the world.”

Increase for poultry, seafood and spices

HorizonScan has seen a significant uptick in hazards over recent months in poultry, seafood and spices.

“Compared to the first quarter in 2017 in poultry we had an increase in incident reports of 199% and compared to Q2 2016 we had a 324% increase – so a huge spike mostly Salmonella in chicken meat from Brazil,” said Stakland, citing a Q2 2017 report.

“In seafood during the second quarter of 2017 we had a 33% increase compared to the first quarter. The big issues that accounted for more than half of that increase were mercury, histamine and parasitic infections.

“In crustaceans the big increase was in veterinary drug residues and that is the most common hazard in crustaceans as many of them are a product of aquaculture, particular in India and Vietnam where these is heavy use of antibiotics and other drugs. The third big mover in the smoked/cured fish category was Listeria.”

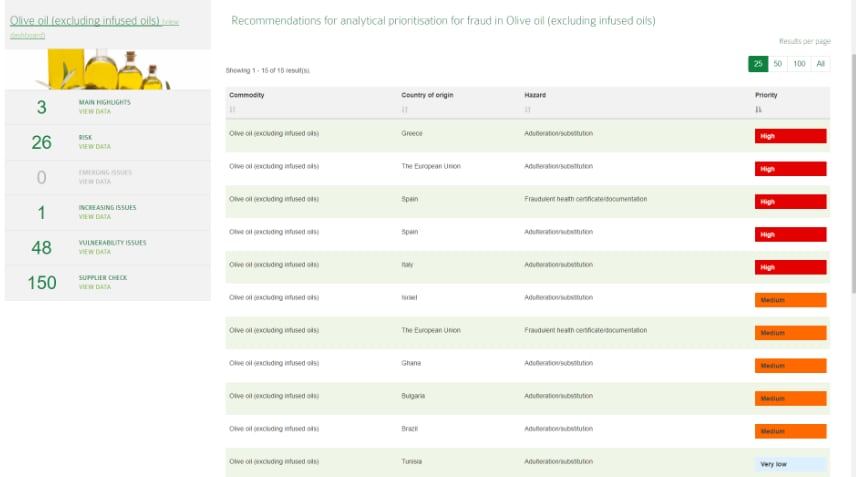

Stakland said spices are prone to fraud or improper labelling.

“During the second quarter of 2017 big increase was in undeclared allergens and some increase in aflatoxins. If you are talking paprika and chilli powder then the big increase is in fraudulent documentation or illegal dye, Sudan dye in particular.”

Risk identified: what now?

Global ID has partners to help people develop mitigation strategies.

“The first step is to identify and rank the hazards, that is where HorizonScan comes in, but then you have to decide what to do about it,” said Stakland.

“Does it require a preventive control under FSMA and if it does what is the nature of that control, who is implementing the control – is it me, the supplier or the customer and I have to validate and document that it is being controlled. We have consultancy partners to help people with the mitigation strategy to demonstrate FSMA or GFSI compliance.”

Everybody ought to be looking at considering and doing risk analysis on their supply chain, said Stakland.

“The single biggest driver is that there are a lot of companies out there that spend a lot of time and energy thinking about brand protection and protecting their customers. The big companies have always understood how critical it is for brand protection not just to have a good recall plan but to avoid a recall in the first place,” he said.

“FSMA has forced people to adopt best practices who might not have been but for the good companies FSMA is not a big paradigm shift because it is really just mandating best practices.

“There’s a group of people specifically looking for FSMA compliance, there’s another group who is involved in FSMA compliance but with an agenda on protecting their brand and making sure products are safe and there are people looking for solutions: ‘My GFSI standard has a requirement of doing a fraud vulnerability assessment and I have tried doing it through Google searches and things and it has taken hours of their time and I am a QA manager I don’t have a minute to spare; please can you help me’.

“We’ve had people creating HACCP and food safety plans look at this and recognise it has a role to play in that, they can say they are using HorizonScan as part of our food safety plan to identify likely risks and to give us guidance on testing and sampling program.”