The firm said its technology inactivates airborne microorganisms (bacteria, viruses, fungi and mould) with greater than 99% efficiency within 0.5 seconds. Indirectly, it diminishes surface contamination by reducing pathogens sedimentation from the air.

It has low power consumption (10-40 watt), efficiency of inactivation does not depend on air humidity and there is no accumulation of microorganisms inside the device which does not need consumables.

The system was backed by an opinion of JSC “Klinski Meat-Processing Plant” (experimental research for microbiological air safety measures) in 2015 and by Wimm-Bill-Dann in 2016 based on results of air decontamination in dairy products.

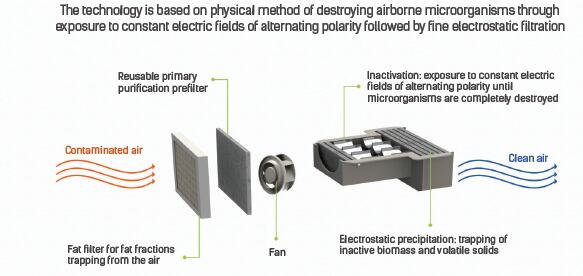

How it destroys airborne microorganisms

Potok told FoodQualityNews the problem of microorganisms’ spread in the air can result in production losses, shelf life reduction, quality decreases, financial losses and reputation risk.

Clients include East Balt Bakeries, Multon CJSC (Coca-Cola), Wimm-Bill-Dann LLC (PepsiCo), Prodo Group, Okraina and Irbit.

NASA has also installed the “Potok-150MK” air decontamination unit in the American segment of the International Space Station.

Potok Bioinactivation Technology is based on a physical method of destroying airborne microorganisms through exposure to constant electric fields of alternating polarity followed by fine electrostatic filtration of inactive biomass and volatile solids.

The first stage is inactivation – repeated exposure to constant electric fields of alternating polarity until microorganisms are destroyed; once inactivated this way they cannot revive.

The second part is fine filtration that involves the capture of destroyed cells fragments on porous nanoelectrodes of the electrostatic precipitator. Filtration efficiency corresponds to the filter class H11-H14.

Potok equipment is used in industries such as healthcare, food, transportation, public facilities and aerospace. Air decontamination devices for each sector differ depending on conditions of production, sanitary requirements and special client requests.

For the food industry, there are standalone recirculating units in metal and stainless steel, induct mount devices in single outward case and laminar flow devices.

“Standalone units for the food industry are used to create a small clean work zone at the place where the product is in direct contact with the air, as well as in small rooms with recirculated air. Such devices due to their portability are designed for more flexible planning of production sectors,” said the firm.

“Induct mount devices are used for air decontamination in the whole room. Depending on the room volume we choose a device of appropriate capacity. Also, Potok devices can be integrated into existing food processing equipment, such as refrigeration units, filling machines, etc.

“As for laminar flow devices, they can be designed for use in premises with high hygiene requirements.”

Operational considerations

The technology is non-selective and all airborne microorganisms are destroyed with no potential recovery after getting to the device’s functional element.

It concerns bacteria (Bacillus subtilis spores, Pseudomonas aeruginosa, E. coli, Staphylococcus, Streptococcus, Salmonella, Listeria); yeasts, mould, fungi (genera Mucor, Aspergillus, Penicillium) and viruses (Influenza virus, Rubella virus etc.).

Supply airflow is fully decontaminated for one pass in 0.5 seconds – so there is immediately clean air in the room, said the company.

The process time depends on the volume of the room, device capacity, conditions of production, including the number of workers in the area.

Potok equipment can operate in nominal mode for full-time working days and in the presence of people.

Devices can work during production to protect products from airborne microorganism contamination and prevent the appearance of new microorganisms with increased resistance to existing disinfections.

The most common air disinfection methods in the food industry include ozone, UV light and high efficiency particulate air (HEPA)-filtration but each of them has shortcomings, said the company.

With ozone production must be stopped during disinfection and some microorganisms are immune.

For UV light there is a low efficiency at high humidity, some microorganisms are immune and there are shadow zones that will not be decontaminated by the UV lamp.

HEPA-filtration involves the risk of trapped viable microorganisms multiplying and becoming a potential source of biological hazard and filtration efficiency is decreased given high air humidity level.