The firm is a manufacturer of real-time trace gas analyzers for low concentration volatile organic compound (VOC) monitoring based on Proton Transfer Reaction – Mass Spectrometry (PTR-MS).

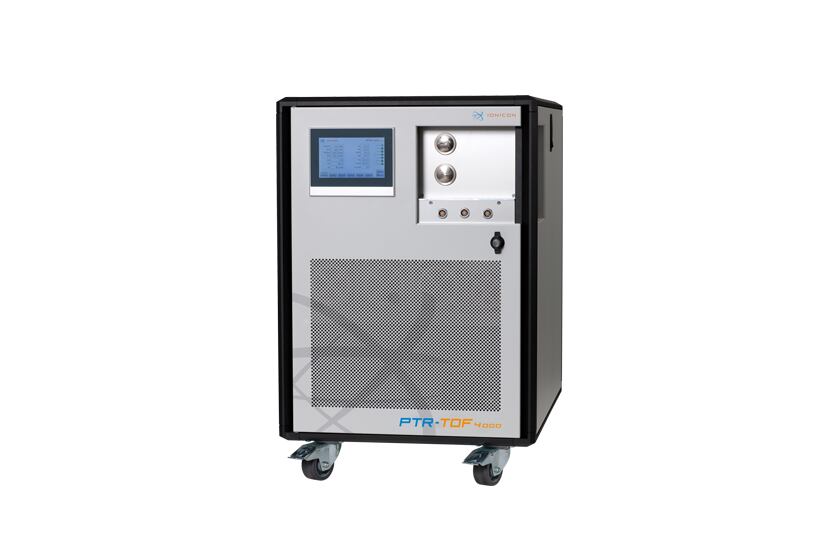

The instrument has a mass resolution of up to 4000 m/Δm and sensitivity of 200 cps/ppbv with a detection limit of below 5 pptv.

Application areas include atmospheric chemistry, environmental research, food and flavour science, illicit substances detection and breath gas analysis.

The PTR-TOF 4000 is positioned in between the PTR-TOF 1000 system and the flagship instrument, the PTR-QiTOF.

Food and flavour science applications

Lukas Maerk, CEO of Ionicon, said PTR-TOFMS is a compact, high resolution, ultra-sensitive analyser for trace VOCs.

“It allows you to detect, monitor and quantify in real-time and you can catch process dynamics with this and this is very important for applications like food and flavour science,” he told FoodQualityNews.

“In food and flavour science it depends if our customers are in academics or industry but typically it is about flavour release monitoring, whatever you can smell or taste and especially for this purpose it is important to catch the exact timing of when the person swallows something or smells something and there is always a dynamic in the process.

“If you brew a cup of coffee at the beginning it is a different flavour or aroma than at the end so this is one of the typical applications. Coffee flavour, cheese also fragrance and flavour creation for the companies who produce flavours and it goes into the process monitoring areas, for example coffee roasting.

“Different ripening stages of cheese, also authenticity, is the olive oil made from extra virgin or is it not, the same is true for other protected geographical areas.”

Customers are interested in flavour, how it tastes, how it changes and how it behaves if they mix it in the mouth.

“The human interaction is very important. What happens if you brew something, if you boil something what aroma will get out and if it cools down how it is changing and then they try to design experiences. Companies do a lot of interesting work as it is all about consumer experience in the end.”

Mass spec and PTR

Maerk said the instrument is a mass spectrometer so the user gets a mass spectrum.

“You get it in real-time, you get it qualitatively but the interpretation of the mass spec is still on your plate. Typically our customers have GC-MS experience and they use this to get a very high time resolution to cover the processes,” he said.

“We also have software tools where we have the intelligence put into the software so the output you get is a quantified substance. So it is not mass spec anymore you see for example acetone, benzene, this is possible but it won’t tell you directly the quality of this food is good or bad, it would need to be set up for this particular application.”

Proton Transfer Reaction is positive chemical ionization used for the ionization of the sample.

“The technology is special, it is proton transfer from protonated water so we create H30+ and we let the sample in, if it collides with the H30+ it takes away the proton and by this gets ionized,” said Maerk.

“The speciality is it is very soft, efficient and it does only ionize the very low concentrated VOCs in air so we do not ionize clean air compounds such as rare gases or Co2 or compounds like that and this is why we are so sensitive.

“Unlike high energetic ionization we typically do not break up the molecules so we do not create a lot of fragments, this allows you to have nice clean peaks which you can quantify. This instrument allows you to analyse the sample without any sample preparation in real-time, the instrument sucks in the sample, it collides with the H30+, it takes away the proton and then it goes to the top for example.”

‘GC-MS is a high resolution picture and PTR-MS is the movie’

Originally developed by the Institut für Ionenphysik at the University of Innsbruck, Austria the technology was commercialized by Ionicon Analytik.

The target market is routine analysis as a mid-range instrument, said Maerk.

“Mostly instruments are differentiated by mass resolution and sensitivity and in both aspects the instrument is in the middle range. Higher end PTR-TOF/MS instruments are predominantly used by academics for analysis of air that is already very clean doing research. GC-MS is the gold standard method if you want to identify something but it takes time and needs sample preparation,” he said.

“So you will never be able to cover a live real dynamic process in a time resolution like we do, it is here in less than a second instrument response time. Whenever you know what you are looking at and want to catch the process dynamics and get a real time picture of it then this is excellent.

“We often compare it to a movie, GC-MS is like a high resolution picture and the PTR-MS is the movie, you can see what happens in between the pictures.

“Our customers are looking for the mass spectra and then they look at the time traces so they look at what happens over time and how much concentration do they have for a particular mass and the higher the resolution of the TOF the better they can separate between different molecules and peaks.

“This allows them to say ‘ok, the acetone level went up by 50% and is now 50 ppb’ this is what they look for.”