Werner Linders said it is common that sites are audited on a periodic basis independent of risk.

“They are audited four times a year if they are high risk or low risk, good performing or bad performing because there is a lack of information. Where we see very interesting opportunities is to go to risk-based auditing and making use of the data to identify those locations where there is most exposure,” he told FoodQualityNews at the Global Food Safety Conference in Houston, Texas.

“Is this in place today? Yes, we have the whole framework mapped out. I don’t know any examples where it is in to that extent but it will be more a matter of months than years away from now. Will that be where it stops, certainly not, but I don’t think there is anyone who knows by linking more and more with the Internet of Things the more we can connect.

“[We have] hand dispensers but the information allows us to understand is there sufficient use of this dispenser in relationship to the number of people that work there and that gives an opportunity to train and reduce food safety risk.”

Linders said the majority of customers were engaging the firm for unannounced audits.

“There could be reasons why announced makes a lot of sense but if it comes to verification of is the system working we would envisage the majority of unannounced,” he said.

“What we see happening is by getting quality data automated to steer where the biggest risk is with less auditors you can reduce a potential risk profile of an organisation.”

Insight through analytics

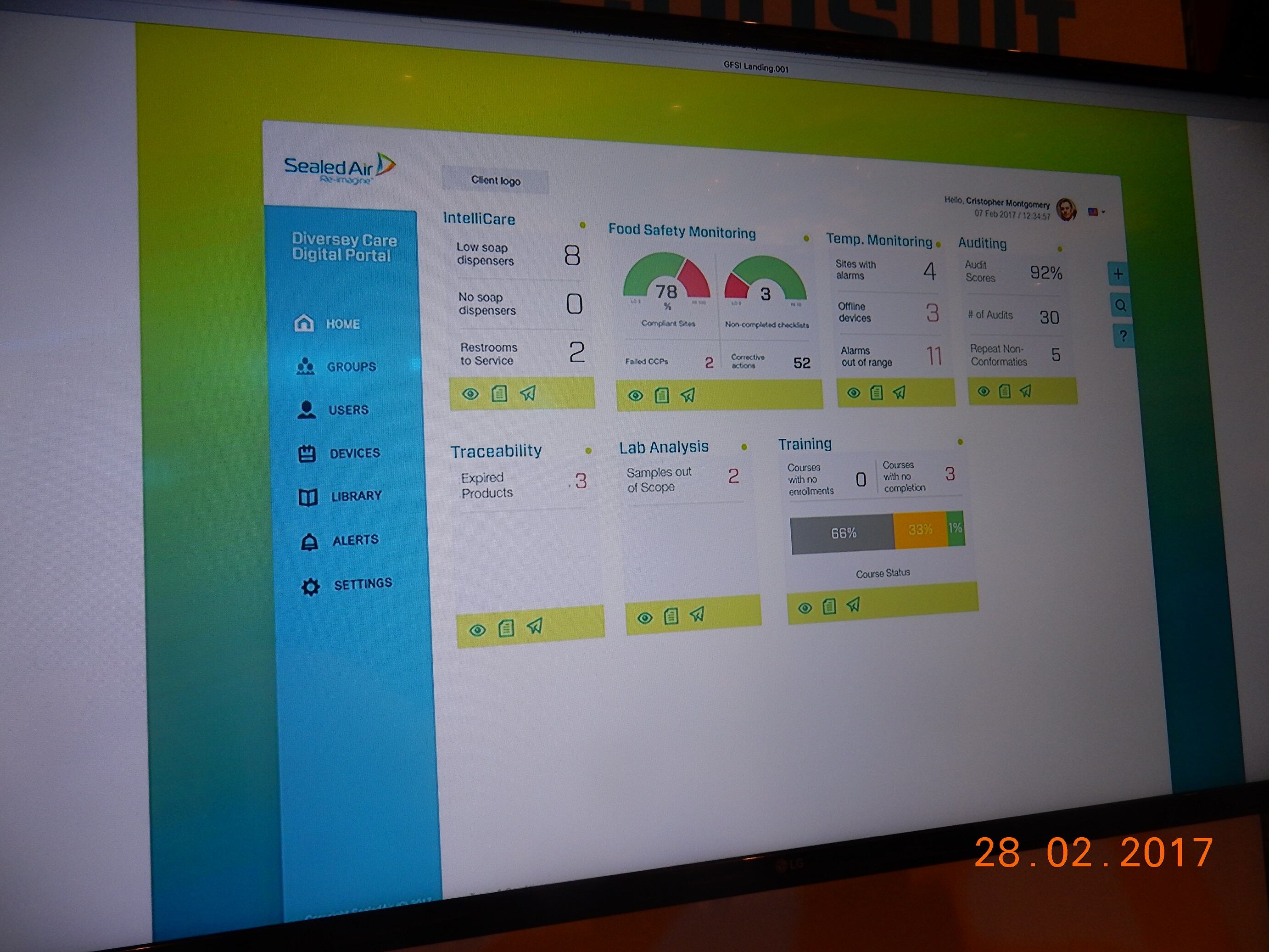

Steve Solvason, global key accounts director at Sealed Air Food Care, said operational efficiencies and food safety are two issues of focus to give manufacturers better insight through analytics.

“The challenge is that food safety is one and optimisation is another so how do you bring those together and keep them in balance,” he told us.

“One of the things we have are services where we can come in that we call checks. So CIPCheck and SecureCheck allow us to come in, analyse the facility and give optimisation strategies on how to improve both of those. Also it is not just operating as a consultant, it is operating in a hands-on manner where we can come in and execute and make sure the opportunities are realised.”

Solvason said certain standards are maintained that were established 10-15 years ago.

“So many times it is something everybody recognises as important but many other factors involved with optimisation take priority. We can make sure you are operating not only on an optimisation level but increase the food safety at the same time from a Three Sigma to a Six Sigma and have the data you are operating within that parameter.”

Solvason said the issue was not access to data but the difficulty to put it into an intelligent form that can be analysed quickly to see trends.

“Much of what we are able to do is take that analytics and make sure you can identify it into a way you can see trends very quickly and easily through the dashboard,” he said.

“What we see many times is customers are over-cleaning and don’t realise that they can meet the same standard of hygiene but be more optimised in the time they are taking.”

Acquiring technology

Sealed Air bought Tampereen Teollsuussähkö Oy (TTS-Ciptec) in July last year.

The company optimizes Cleaning in Place (CIP) systems through remote monitoring and predictive analytics.

Sealed Air Diversey

Sealed Air Corp is said to be in talks to sell Diversey Care to private equity firm Bain Capital for between $3bn and $4bn. Previous rumours had Henkel in the running but the German consumer firm has since offered to buy Darex Packaging Technologies for $1.05bn.

Sealed Air said last year that it planned to spin-off Diversey Care and the related hygiene business by the second half of 2017.

It sold Diversey Japan to the Carlyle Group for $377m to focus on higher growth markets in 2012.

The firm bought Diversey, which serves brewers, beverage bottlers, dairies and food processors, for $4.3bn in 2011.

Traditional CIP metrics measure flow, conductivity and temperature, which can indicate the cleaning cycle has met predefined parameters but cannot indicate the clean level.

The CIPTEC Spectrophotometer measures light travelling through the liquids inside a CIP system; measuring the volume of soil in and the cleaning chemical level in the final rinse stage to determine the effectivity of CIP stages and removal of soils.

“Up to this point there have been recipes put together on various rinsing, detergent, sanitation steps that somebody would take that may have been in place for 10 years. What the Ciptec technology does is allow you to actually look inside the pipes to see what’s happening during each one of those cycles,” said Solvason.

“For example you may have something that is going on for an extra 10 minutes out of a 20 minute cycle that is adding absolutely no value or no benefit in the cleaning cycle. Through the Ciptec technology we allow you to see where you are within the cleaning cycle, if you are adding any extra margin of safety to it or not.”

Managing multiple locations

Given the multiple of sites it was important for organisations to be able to remotely capture data, according to Linders.

“That for us is a relatively young trend. There are some exceptions who were, for instance, measuring some individual components,” he said.

“What we see when it comes to data is first of all capturing; and capturing could be automated temperature monitoring or digitalising the checklist which is still done on paper and I think that is where we are today and will be for another couple of years. Today it is moving the industry from paper to capturing the data.”