Micropore is a UK-headquartered manufacturer of specialist equipment for particle and emulsion manufacturing. By swapping fat particles for water droplets, its patented membrane emulsification system, LXF-1, is at the forefront of healthy reformulation.

LXF-1 allows for nearly mono-dispersed droplets of the 'dispersed phase' - such as water droplets - into the 'continuous phase' - such as chocolate - whilst maintaining the creamy sensory taste requirements and mouthfeel.

FoodNavigator spoke to Dave Palmer, the firm's business development manager about the benefits.

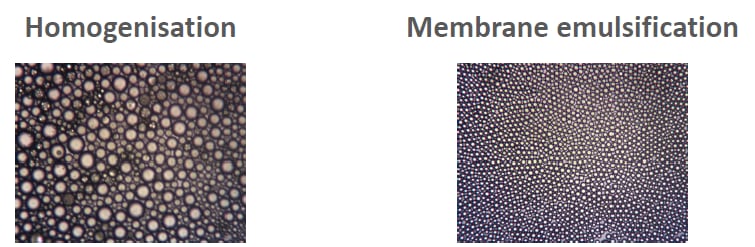

While membrane emulsification and using air and water emulsions to achieve calorie reductions is not new, he said, this has traditionally been achieved through homogenisation techniques. These tend to give a broad particle distribution resulting in a final product that is inherently unstable. Mayonnaise that separates, for example, is because the larger particles are more buoyant while the smaller particles remain suspended.

“Adding water needs to be done in a very controlled way and the droplets need to be the same size because otherwise it can affect the mouthfeel or melting point.

“We proved we can reduce the amount of fat without having adverse effect like bloom or discolouration, and keeping good shelf stability [which is] on a par with normal chocolate.”

Another benefit of Micropore’s membrane emulsification is that it uses food-grade stainless steel membranes – as opposed to glass ones used by its competitors – which means it can easily (and safely – no shards of glass) be scaled up for food production.

From chocolate to cheese, rocket fuel to pharma

Micropore has worked with a number of food manufacturers that sell reduced-fat cheese or low-calorie chocolate across Europe and the US, achieving between 15 and 20% fat reductions.

But the process can be applied to other foods.“We’ve worked with these foods [chocolate and cheese] because that’s been the market drive. But there’s no reason why it couldn’t work in any dairy product such as margarine or yoghurt - anywhere you have a suspension of water in fat.”

This technology is used across a number of industry applications – Micropore has applied it to cheese, chocolate, pharmaceutical capsules and even rocket fuel.

Due to the nature of its equipment, Micropore doesn’t offer air emulsions but its food application liquid emulsions are not limited to water.

The company has also added manuka honey to chocolate. "[Honey] has a very high viscosity and can be difficult to work with, our technology allowed it to be evenly dispersed through the product, in uniform sized droplets," he added.

'A way to tackle obesity'

There is not much consumer awareness of this technology but Palmer believes manufacturers should be transparent. “As long as you publish accurate facts on the packaging it’s not dishonest or underhand. If anything it's one way to tackle growing obesity.”

Steve Osborn, founder and commercial director at food consultancy Aurora Ceres, agreed. “The battle against obesity is a complex one. Whilst the basic premise of ‘eating less, and

exercising more’ is very simple, as a society we are used to plentiful food and live in a world which is driven by convenience.

“We are also presented with a fantastic array of foods – many of which are calorie dense, and whilst it can be easy to say ‘give up the chocs’, the reality is much more challenging. The food industry is being challenged constantly to provide healthier and less calorie dense products – so if these options can be exploited then it is meeting consumer demand,” he said.

“Likewise if there is no reduction in quality then it is surely of benefit to the consumer. Since all products have clear ingredient declarations, weights and nutrition there cannot be anything considered as misleading. The only challenge could come as new emulsifiers and other additives are required to help achieve the reduction in calorie density, which may not fit into the clean label agenda,” Osborn added.

Researchers at the University of Birmingham have developed patented air-protein emulsions with air-filled protein coated droplets that can be substituted for fat in emulsions to enable production of low fat foods.

But cost could be a barrier to membrane emulsification for some applications when compared with other tactics, such as swapping sugar for non-nutritive sweeteners. “Air and water are always great as they are generally cheap – however it’s not necessarily cheap to get them [into a product]," said Osborn.