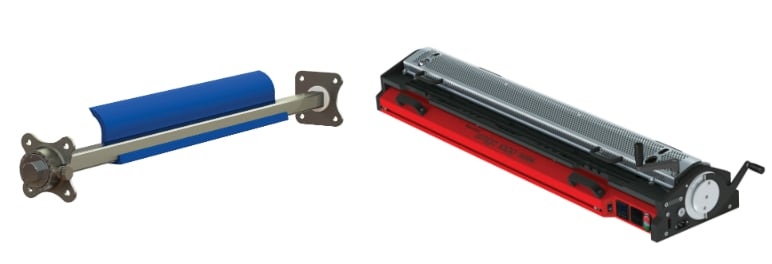

Flexco will reveal its range of conveyor belt-joining products, the Novitool Amigo, at the show in Frankfurt, which takes place between 7 and 12 May this year.

Conveyor belts are a key part of the food processing industry, used to transport products from various workstations like washing, grinding, cutting, cooking, deboning, slicing, portioning, weighing and a plethora of other sector-specific areas.

Bacteria breeding ground

Belt joints, Flexco said, are a crucial part in this process. The company explains that belt-joiners have to comply with stringent hygiene regulations as meat, in particular, can be a breeding ground for bacteria and fungi.

“Belts made of thermoplastic materials, such as PVC or polyurethane, are predominantly used in the meat processing chain,” said Harry Schiminski, Flexco’s product manager.

“The ends can be joined mechanically or spliced to make endless belts. In an endless belt the two ends are welded together, creating what seems to be a continuous unit. This joint is stable, extremely durable and, because it is seamless, no deposits accumulate.

“Novitool Amigo is a press which enables users to join conveyor belts quickly and easily without removing them from the system,” he added. “It regulates the process and creates a controlled and uniform connection.”

No comment on cost

Flexco claimed that use of the Novitool Amigo press can help businesses “significantly reduce their maintenance costs”, although Schiminski declined to put a ballpark figure on the amount it could save companies.

He did say the Novitool Amigo press had a “pre-heating function which removes any moisture in the belt” and which help prevent air from getting trapped.