The firm was awarded its first patent by the US Patent and Trademark Office (USPTO) for its phage engineering technology earlier this month.

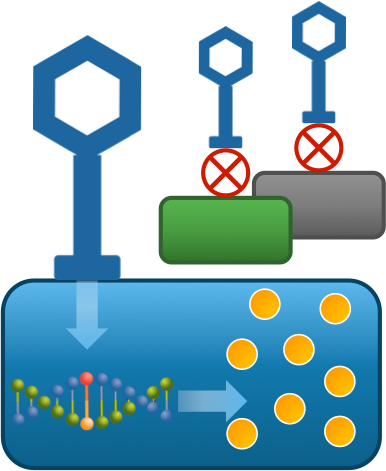

Model phages were engineered using molecular biology techniques to deliver heterologous protein products to bacterial cells.

Phages work by breaking down bacterial cell walls using enzymes, which prevents the replication and spread of the bacteria.

Phage engineering ‘at core’ of process

Dr Michael Koeris, VP of R&D, said phage engineering is at the core of the company’s food safety process.

“Bacteriophages to kill Salmonella, Listeria or E. coli exist presently but detection is a different story, they are not useful as they kill the cell so we had to modify the bacteriophage to produce a detection marker.

“It is not easy to mess with bacteriophages on a molecular level…or to do this in a timeline that works for commercial operation. You can’t use bacteriophages for just any kind of assay, their strength is that they are very target specific.”

Koeris said bacteriophages are specific for bacteria, as in they find that specific bacteria and kill it.

“They are small and you can’t easily manipulate them with traditional molecular biology methods. Instead of that we’ve used a tool that’s originally been developed for the human genome sequencing project called a YAC (yeast artificial chromosome).

“The captured bacteriophage genome is stable and inert in yeast, which it is not in a bacterium, as the bacteriophage will quickly kill the bacterial cell. Once the artificial chromosome exists stably in yeast however, you can manipulate it with traditional methods and then use a technique we developed called YAC-to-Plaque (Y2P) to reboot the bacteriophage genome.”

Patent phrasing

The US Patent No. 13/627,060: “Recombinant Phage and Methods” contributes to Sample6’s process for phage engineering.

They found that phage genomes are not lethal in yeast cells and phage can be cloned into suitable vectors and propagated in yeast as part of the process to develop recombinant vectors comprising phage genomes.

Different phages may contain different materials but they all contain nucleic acid and protein, and may be covered by a lipid membrane. Depending upon the phage, the nucleic acid can be DNA or RNA but not both and it can exist in various forms.

The size of the nucleic acid varies depending upon the phage. The simplest phages only have genomes a few thousand nucleotides in size, while the more complex phages may have more than 100,000 nucleotides in their genome.

The number of different kinds of protein and the amount of each kind of protein in the phage particle will vary depending upon the phage. The proteins function in infection and to protect the nucleic acid from nucleases in the environment.

Dr Koeris said the patent was applied for four and a half years ago.

“We had to convince the examiners that what you call prior art, and that currently going through the system, was not inventing what you invented. It was important not to claim too broad a thing of what we could do.

“We had to explain why prior art and journal articles that existed before we applied for the patent, why they were not relevant and ours was special, it comes down to proof. Thinking of something good doesn’t make it patentable.”

Sample6 DETECT is an enrichment-free, on-site, in-shift pathogen diagnostic assay.

Approved by the USDA and AOAC, Sample6 DETECT/L is an in-plant, in-shift pathogen detection for Listeria.

Sample6 CONTROL is a software platform, which can be used to plan, execute, remediate and analyze food safety programs.

“As an industry, we need to set a new bar for food safety programs – widespread illness outbreaks and massive recalls should not happen in this day and age. Contaminated food should be found and stopped before it ever enters the food chain,” said Sample6 CEO Tim Curran.

The company helps ensure food safety at more than 30 plants in the US and Canada, including ice cream, soy product and consumer packaged meats suppliers.