The firm has worked with SteriTouch and Vinyl Compounds, a sister company of Eagley Plastics, on the development.

It supplies the catering and food processing industry including strip curtains for cold stores and chillers, in warehouses and factories where frequent forklift truck or pedestrian access is required, room or area partitions and as a barrier against temperature, noise and dust pollution.

Use of strip curtains

Andrew Alty, managing director and CEO of Strip Curtains Direct, told FoodQualityNews the product allows them to cement a place in the food processing industry.

“The purpose of strip curtains in food production is to control temperature in chillers and entrances to walk in fridges, they are a constant barrier that you can put pallet trucks through or people can push through. They last between six and 12 months depending on the amount and kind of traffic passing through them,” he said.

“We have manufactured PVC strip curtains for some time and lots of people were doing what we were doing but we were lucky to have the partners to create this antimicrobial version which sets ourselves apart from the market.

“The additive was used in cladding for walls to create a hygienic environment and in a meeting one day we came up with the idea of using the same additive in strip curtains.

“If it prevents one case of food poisoning in customers or down the food chain it has done its job.”

The SteriTouch strip curtain creates an anti-microbial barrier to protect against bacteria, including E.coli, MRSA, Legionella and Salmonella and mould and fungi.

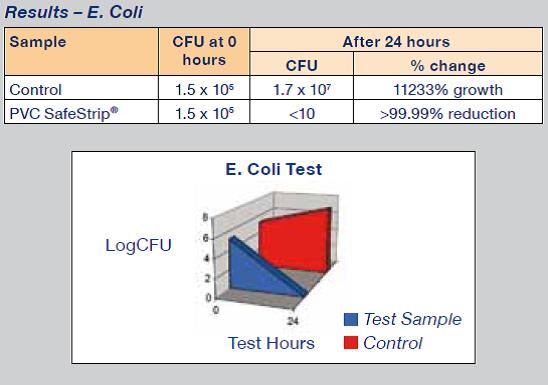

Products containing SteriTouch are tested at an independent laboratory and the group claims results show they are proven to be at least 99.9% effective against MRSA and E.coli.

How the additive works

Joanna Wilson, marketing manager at SteriTouch, told us that the additive is supplied as a masterbatch and added at the dosing stage.

“It requires no processing changes and does not affect the look or feel of a product. End products are sent for independent laboratory testing to verify their antimicrobial performance,” she said.

“The standard laboratory test looks for reduction in MRSA and E.coli, and independent testing of the strip has demonstrated 99.9% efficacy against these organisms.

“The additive used in the strip curtains has also proven very effective against Campylobacter, Salmonella and Listeria.”

Wilson claimed food factories using the strip will benefit from reduction in cross contamination, exceeding HACCP criteria and extending the life of the curtains.

SteriTouch has been working with Strip Curtains Direct since early 2014, following a partnership with Vinyl Compounds.

The Silver ions embedded in the material substrate are released via ambient moisture and enter the cell membrane. They destabilise it, stop respiration and inhibit cell division, whilst blocking the replication of DNA.

Wilson said the masterbatch used in the strip curtains is based on silver ion technology, which is non-leaching and non-sensitising.

“Silver has been used for thousands of years for its antimicrobial properties, and works by several methods, ensuring that bacteria will never become resistant to it. The antimicrobial effect is permanent, and is unaffected by even the strongest cleaning chemicals.”

The active components are approved by the EPA and FDA for food contact, and are notified on the Biocidal Products Regulation.