It is a mandatory standard for accredited laboratories that perform microbiological testing of food, animal feed or water using culture media.

The standard was compiled by a joint ISO working group from food and water standardization and titled “Microbiology of food, animal feed and water – preparation, production, storage and performance testing of culture media”.

EN ISO 11133:2014 defines the preparation and quality control of culture media, the requirements of which are applicable to all categories of culture media prepared for use in laboratories performing microbiological analyses.

This standard replaces EN ISO TS 11133-1:2009 (Preparation of culture media), EN ISO TS 11133-2:2003 (Performance testing of culture media, both for food and feed microbiology), and ISO 9998:1991 (Requirements for microbiological media for water testing).

EN ISO 11133:2014 applies to any commercial or non-commercial entity that is producing and/or distributing culture media intended for the microbiological analysis of food for human consumption, animal feed and samples from the manufacturing environment of such products and water for consumption or use in food production.

The standard includes all types of culture media, ranging from dehydrated to ready-to-use media for classical to alternative microbiological testing methods.

All European Union (EU) countries are adopting EN ISO 11133:2014 and the standard is published in French and German. All accreditation bodies worldwide recognize EN ISO 11133:2014 because it is now a full EN ISO standard.

Overview of EN ISO 11133:2014

EN ISO 11133:2014 covers requirements for the preparation, production, storage and performance testing of culture media. All conditions for performance testing should resemble the intended sample testing conditions as closely as possible to provide the most accurate and meaningful results.

For example, culture media for quantitative testing must now be tested quantitatively, and media used in conjunction with membrane filters must be tested in combination with these membrane filters.

The requirements for performance testing are specified in detail, which includes step-by-step instructions and flow charts for both performing and evaluating performance tests.

EN ISO 11133:2014 provides comprehensive specification tables for most culture media for food and water microbiology. These tables include: the medium’s target microorganism; relevant ISO standard; each medium’s function to be tested (productivity, selectivity, specificity); the appropriate control strains for each medium’s function, including their World Data Centre for Microorganisms (WDCM) numbers, and; test criteria and/or characteristic reactions and other practical information.

EN ISO 11133:2014 contains detailed instructions for the maintenance of microbial strains and the preparation and standardization of working cultures and inoculation suspensions.

It specifies the optimal number of colony forming units (CFU) per plate or membrane filter and describes how productivity ratios and limits are to be determined.

Quality assurance responsibilities

Many laboratories source their culture media from suppliers to streamline their workflows and to ensure quality and batch-to-batch consistency.

EN ISO 11133:2014 takes into account the ever-increasing number of laboratories sourcing their culture media from suppliers by stipulating quality assurance requirements for laboratories that continue to prepare their media in-house and for manufacturers of culture media.

With a clear line between the responsibilities of users and suppliers, laboratory managers can reliably evaluate which duties and responsibilities will transfer to the manufacturer when they make the decision to procure culture media from a supplier.

For laboratories that continue to produce culture media in-house, each batch can sufficiently be tested using a single test strain named in the standard. Manufacturers must test each batch using several microorganisms.

Laboratories can rely upon the performance tests that the manufacturer conducts for ready-to-use media only as long as the transport conditions are observed and the manufacturer’s quality control (QC) test is performed according to the requirements of the standard.

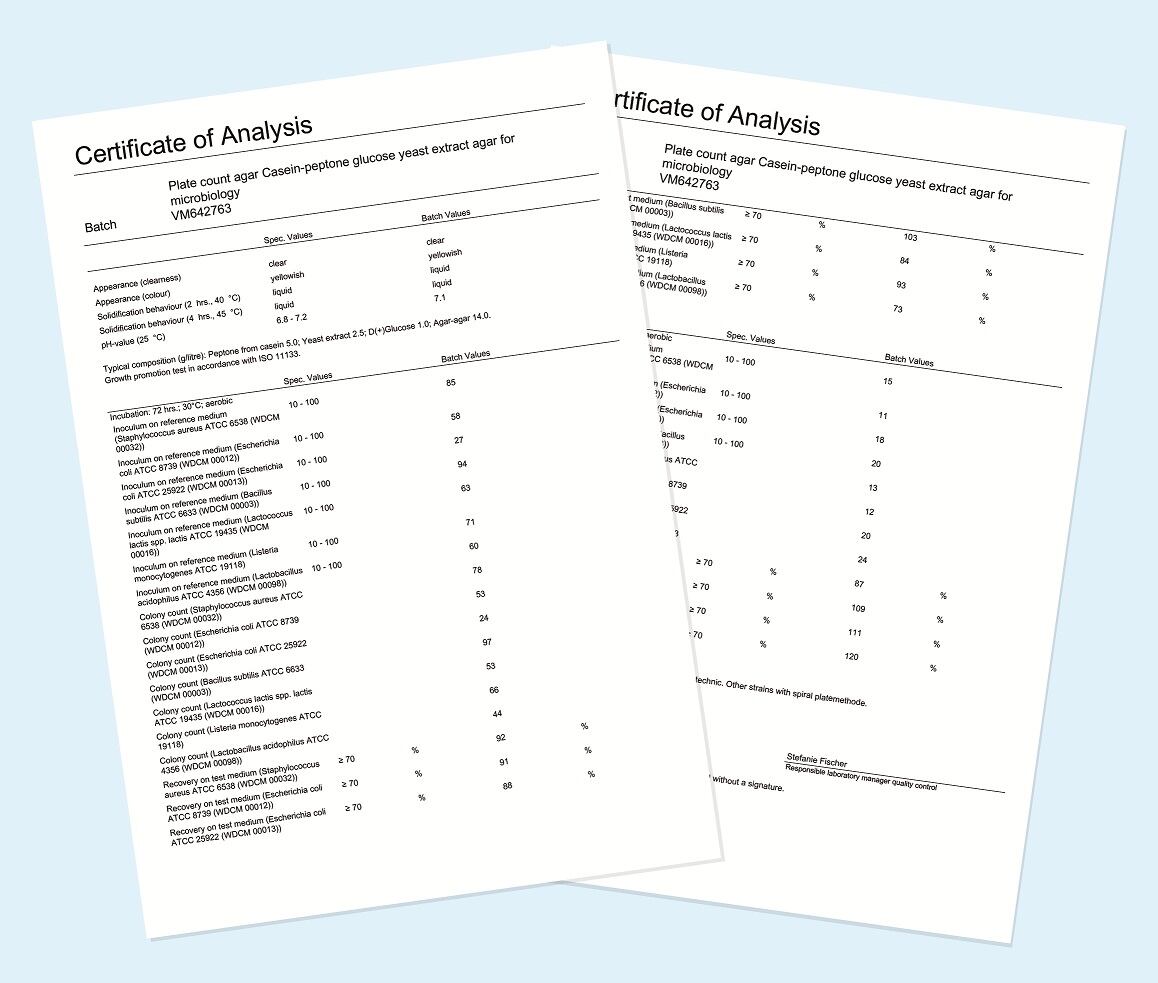

It is the end users responsibility to ensure that batch testing was performed according to the requirements of EN ISO 11133:2014 by getting the quality control certificate as a supporting document from the manufacturer. This certificate should disclose the test organisms used, the acceptance criteria of the performance tests and test results.

Performance Testing

Suppliers must conduct rigorous qualitative and/or quantitative testing on all ISO 11133:2014 compliant culture media that they provide to laboratories. Below are a few examples of testing criteria for liquid and solid selective and non-selective culture media.

Buffered Peptone Water (BPW) is used for the non-selective pre-enrichment of Salmonella bacteria in food. The EN ISO 11133:2014 testing criterion for BPW is turbidity, which must either be weak or good.

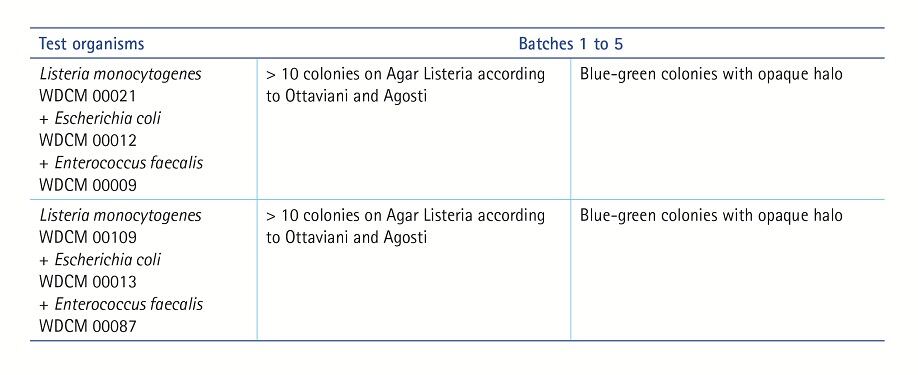

Fraser broth is used for the selective enrichment of Listeria monocytogenes in food. The EN ISO 11133:2014 testing criterion is the growth of more than ten colonies on Listeria selective agar according to Ottaviani and Agosti.

When inoculated as a mixed culture with Escherichia coli and Enterococcus faecalis, only L. monocytogenes should be able to grow on this agar as characteristic blue-green colonies with opaque halos. The E. coli and E. faecalis strains are included in the testing criterion to prove the selective properties of the medium.

Two common solid agar media from Merck Millipore are selective de Man, Rogosa, Sharpe (MRS) agar for enumeration of lactic acid and non-selective Plate Count Agar (PCA) for colony count. The EN ISO 11133:2014 quantitative productivity testing criterion for each of these solid media agar is recovery rates of 70% or more for every test organism.

Conclusions

The goal is to improve consumer safety with respect to food and beverage products, and the guiding principle is that performance testing conditions should mimic the intended sample testing conditions as closely as possible.

Under the standard, laboratories that source their culture media from a supplier can ensure that the media is manufactured and certified according to the latest international standard, EN ISO 11133:2014, by procuring the quality control certificate as a supporting document.

Ultimately, this standard should reduce the workload for the qualification of new culture media batches from suppliers.

In the supporting document, suppliers should provide quantitative information about the growth of both ‘wanted’ microorganisms (bacteria that should grow on a specific medium) and ‘unwanted’ microorganisms (bacteria that should not grow on a specific medium).

The highest quality media will support only the growth of ‘wanted’ microorganisms.

- Barbara Gerten is an application training scientist at Merck Millipore, a member of the ISO committee for microbiological standards regarding food and water testing and was involved in the revision of EN ISO 11133.