The invention, filed as a patent application by Mondelez R&D arm Kraft Foods Global Brands and made public last week, involves blending a polyglucitol with ingredients, which maintains the majority of added water.

Energy saving process

The company said in its application: “It was surprisingly found that the above method of forming confectionery eliminates the cooking step while forming a confectionery."

“Since the cooking step is eliminated, the method requires significantly less energy to form the confectionery composition, and heat sensitive components can be incorporated into the confectionery composition.”

No impact on flavor and feel

Mondelez said that the method reduced the number of steps involved for traditional methods, thereby simplifying the process.

“Also, the method produces confectionery compositions which are substantially similar to a cooked candy in taste, texture, and feel,” it said.

Hydrogenated polysaccharide

According to Mondelez's patent application, “cooking” was a process that required temperatures above 100° C.

Under its invention, a polyglucitol (specifically a hydrogenated polysaccharide) is blended with other ingredients at a temperature between 50° C and 80° C to form the hard or chewy candy.

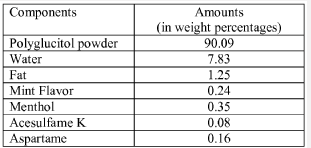

Mondelez lists specific weight measurements for the polyglucitol in its application.

“The method does not require the use of elevated temperature or high shear force. The method also avoids the need for a hydrated hydrobinding component and components that produce a chalky texture.”

Gum manufacture

The firm said chewing gum could also be produced using this process. The application said that the polyglucitol could be blended at any stage of the gum manufacturing process, but expressly mentioned adding the ingredient just after conventional mixing.

The method works for gum prepared using a batch or a continuous method, it said.

In the company’s tests, it used Roquette’s POLYSORB polyglucitol powders.