Dr Jaime Grunlan, Assistant Professor in Mechanical and Chemical Engineering at Texas A&M University, said the transparent nano-film combines particles of montmorillonite clay, a soil ingredient used to make bricks, with a variety of polymer materials.

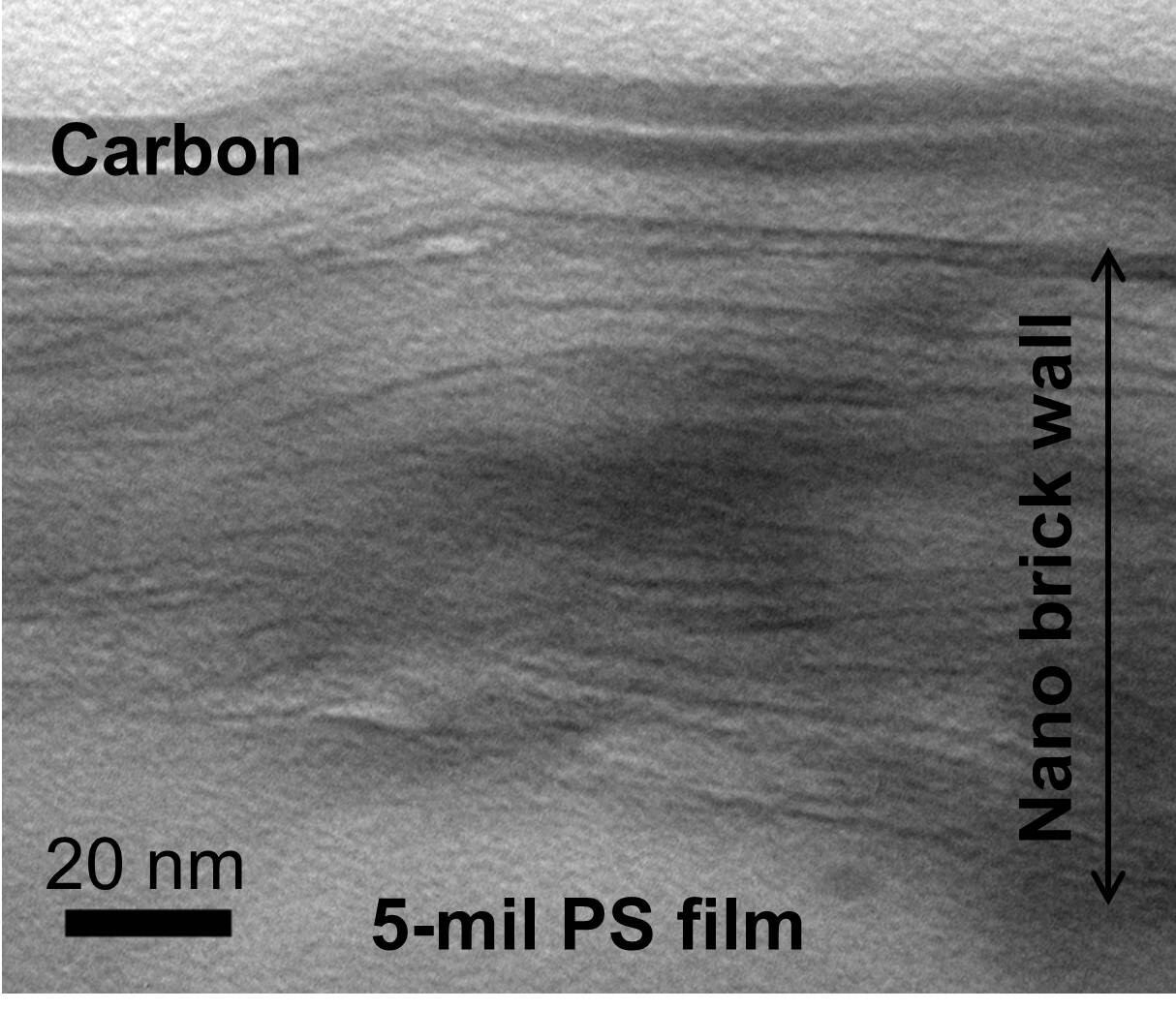

"When viewed under an electron microscope, the film looks like bricks and mortar," he said "That's why we call it 'nano-bricks'."

The coating, around 100 nanometers thick, is about 70 percent clay and contains a small amount of polymer, making it more eco-friendly than current plastics, said Dr Grunlan.

When layered onto existing materials such as polylactic acid, PET, polystyrene and polycarbonate films, it added strength and provided an improved barrier to oxygen, he told FoodProductionDaily.com.

Lab studies had shown the film to be 100 times less permeable to oxygen than existing silicon oxide coatings. This means it's also likely to be a better oxygen barrier than a metal coating, whose permeability is similar to that of silicon oxide, Grunlan noted.

Exceptional barrier

He said the barrier performance can be tailored by changing the polyelectrolytes, clay and number of layers.

"Others have added clay to polymer to reduce (gas) permeability, but they are thousands of times more permeable than our film," Grunlan added. "We have the most organised structure — a nano-brick wall — which is the source of this exceptional barrier. This is truly the most oxygen impermeable film in existence."

The scientist is currently working on improving the quality of the film – including boosting moisture resistance – to make it more appealing to packaging manufacturers. Future developments could include nano-bricks that contain anti-microbials and block UV light to enhance performance and product quality.

The coating could be applied either by dipping or spraying.

Grunlan said no shelf life testing had yet been done with real food and the coating was a platform technology that needed to be paired with a food packaging company.

“With the right partner, we could be less than a year from commercialization,” he said. “All proof of concept is complete with regard to properties and continuous - roll-to-roll - processing. I am very interested in finding partners for food packaging.”