MadeRight: Mycelia-based packaging pioneer mushrooms with investment

MadeRight is developing a sustainable alternative to plastic packaging with fungi. Leveraging a fermentation process that sees mycelia cultivated from industrial organic waste, the start-up wants to produce high-performance materials for industry.

Today, the MadeRight is announcing it has secured $2 million (€1.85m) in funding to progress its fungi-based packaging innovation towards the next milestone.

Specifically, the start-up plans to direct the funding towards expanding its development team and refining the production process of its mycelia-based packaging technology.

The funds will also support marketing efforts, helping MadeRight to enter new markets worldwide.

The investment was led by Israeli food processing and technology incubator Fresh Start, with participation from Arkin Holdings and Arc Impact.

Mycelia-based innovation for packaging

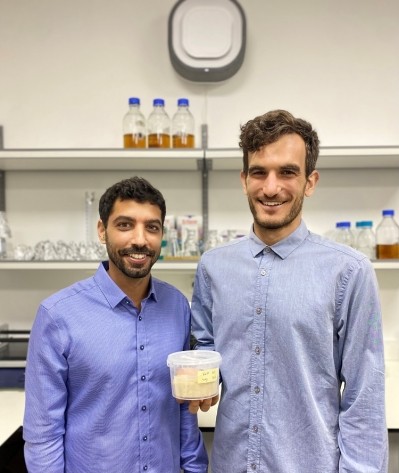

MadeRight was founded by mycology expert Rotem Cahanovitc, who currently serves as the start-up’s CEO, and CTO Yotam David, a molecular geneticist. The

company is using fungi as cell factories to produce high-value materials, with its first product turning industrial organic waste into a recyclable plastic alternative.

“Currently, there is a trade-off between performance and sustainability,” according to Cahanovitc. “We frequently encounter fossil-based materials that provide an extended shelf life but harm our planet, or sustainable materials that are recyclable or compostable but lack sufficient shelf life.

“MadeRight, however, is pioneering the production of novel materials derived from fungi, striking a balance between high performance and sustainability.”

Conventional plastic packaging is made up of different materials such as polymers, pigments and fillers in varying ratios, Cahanovitc recently told FoodNavigator. Functional additives are also included to protect against relevant elements such as oxygen or light. This is where MadeRight comes into play: the start-up is developing a ‘low volume, high value’ constitute for packaging to improve the performance and sustainability of bioplastic.

The company’s fungi-based solution mixes in with these plastics to enhance their performance, we were told. The solution is developed using a solid-state fermentation process, whereby fungi turn would-be waste into biomass. Then following several biotechnological steps, MadeRight extracts materials from the biomass to mix in plastics and create pellets. The pellets, Cahanovitc explained, are a ‘drop-in’ solution – meaning they can be introduced into existing packaging manufacturing machines.

Encouraging recyclability with fungi

The need for sustainable packaging solutions is obvious. An estimated eight million tonnes of plastic pollution enter the marine environment every year, and in a business-as-usual scenario, there could be more plastic in the ocean than fish by 2050.

Of the estimated 460m tonnes of plastic is that is produced annually, 141m tonnes are thought to be attributed to food and beverage packaging. According to the Ellen MacArthur Foundation, just 14% of the plastic packaging used globally Is recycled – while 40% ends up in landfill and one-third leaks into the environment.

“Despite the recyclability of many packaging materials, global recycling rates remain low at around 10%, mainly due to plastic additives mixed into the packaging to extend product shelf life,” explained Cahanovitc.

“These additives hinder recyclability, and MadeRight aims to replace them with sustainable fungi-based materials.”

MadeRight aims to develop a commercially applicable prototype for plastic and packaging producers by the end of 2024.

Co-founder and CEO Rotem Cahanovitc will be pitching MadeRight’s innovation at Climate Smart Food. Broadcast over three days (19-21 September, the free-to-attend digital broadcast event will ask how to transition towards a climate smart food system.

The full programme is available here and for free registration click here.