CuanTec uses chitin, an inedible molecule, found in the parts of shellfish that are normally discarded, and converts it into durable, antimicrobial and biodegradable food packaging for seafood. By processing the chitin into chitosan and mixing it with starch-based biopolymers, the firm creates a flexible, stretchy film wrapper, much like cling film.

The idea came from Ryan Taylor, an analytical chemist, former student of Strathclyde University and CuanTec’s chief operating officer. Taylor pitched his idea to Strathclyde Entrepreneurs Fund, which invests in business ventures by the University community, and the company was born.

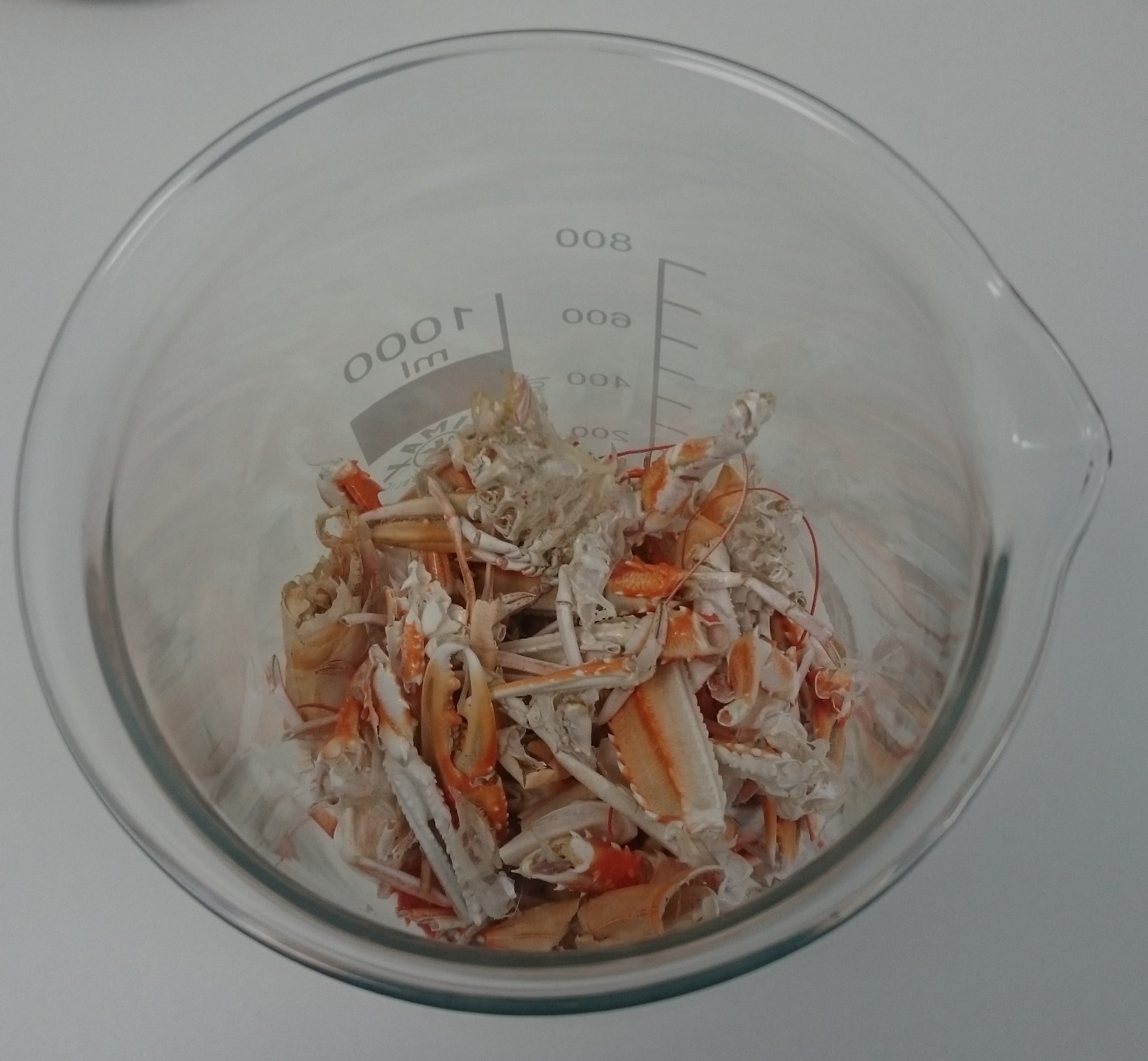

CEO of the company Cait Murray-Green told us: “We take the parts of langoustine we don’t eat – the shell, head and other crunchy bits - and extract chitin, which is

the second most naturally abundant biopolymer in world. It’s present in the shells of crustaceans, insects and even mushrooms - it’s all around us.

“It’s a nice, little circular economy story. We take langoustine waste from their shells, stretch it in a slightly different way and wrap them up in it again.”

What’s more, the film itself could reduce the need for preservatives thanks to the antimicrobial properties that naturally occur in chitosan.

This quality is already well known – it's commonly used to protect seeds during storage for instance - and while the researchers are still in the laboratory doing tests, they hope the end-product will cut out the use of preservatives.

“The salmon steaks you purchase that normally last three days could be extended to six or seven days thanks to the packaging,” said Murray-Green.

“Lots of food currently uses metabisulfites and it has advantage of preserving meat but some people are allergic to it. It’s also a bit of a health hazard because of the fumes that are created when producing it, so we are looking for alternatives. We hope our process will be of benefit in that area.”

The firm, which secured equity investment from the Scottish Investment Bank and Gabriel Investments as well as an innovation grant from Scottish Enterprise, already has a number of prototypes under its belt and is currently testing for safety and allergens in order to be compliant with EU regulations.

It has also seen a lot of interest from retailers, seafood processors and fisheries, and is aiming to see the plastic on shelves in 18 to 24 months.

Cost-wise, the film will be more expensive than its petro-chemical equivalents, said Murray-Green, but not prohibitively so – and it will have the added benefit of prolonging shelf-life and not ending up in a landfill site.

Moving on to mushrooms

CuanTec currently only uses langoustines - Scotland has an abundant, steady and pollutant-free supply coming from the North Atlantic - but it is already eyeing up

other potential raw materials.

“In the future we’re very set on expanding to other ingredients - lobster, cray fish, crabs but also insects or mushrooms, which would help us get into markets where animal sources of chitosan is an issue. At the minute our product is not suitable for the Israeli or Indian markets, for instance, or for vegans."

Energy-friendly production

There are currently no chitosan extraction plants in the UK that operate on a commercial scale, and traditional extraction methods involve large quantities of chemicals and energy which make it difficult to become financially viable.

But CuanTec uses a biological fermentation method which reduces the need for heat and, therefore, energy. “It’s like brewing at low temperatures and although it does take longer, we have a much lower cost for extraction and it’s more environmentally friendly,” said the CEO.

Actual commercial-scale ‘brewing’ times haven’t been defined yet but CuanTec plans on opening an industrial production plant in Scotland, ideally near the fisheries, before moving beyond and perhaps even overseas.