‘A different level of complexity’: Meat alternative start-up mimics fibrous texture of pork whole-muscle cuts

The new meat alternative has been named ‘pork skewer 2.0’, in reference to the animal counterpart (1.0) from which it was designed.

The title “expresses our aim of creating a ‘successor’ of meat, not just a simple analogue,” Novameat founder and GEO Giuseppe Scionti told FoodNavigator.

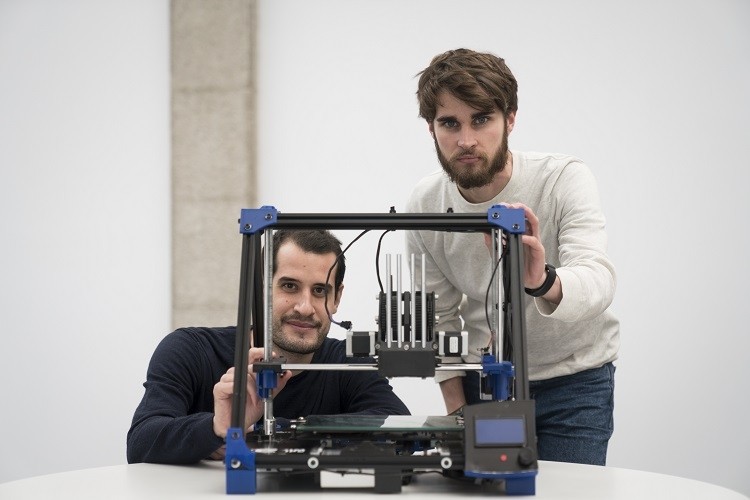

Indeed, Novameat’s products could not be described as ‘simple’. The Spanish start-up leverages 3D printing technology to mimic meat’s fibrous texture, using plant-based ingredients.

“We developed [pork skewer 2.0] working remotely, using our biomimetic micro-extrusion technology, and though our custom 3D printing machines,” explained Scionti.

‘Moving beyond ground meat analogues’

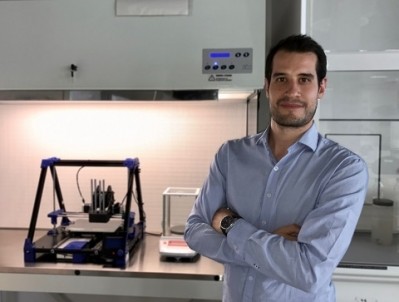

Novameat’s technology is founded on a discovery Scionti made while working as a researcher and assistant professor in bioengineering at the University of Catalunya.

Here, the founder worked out how to ‘bio-hack’ the structure of the native 3D matrix of several plant-based proteins, in order to achieve a meaty texture. Today, the start-up’s technology ‘finely tunes’ the structure of these proteins at the microscopic level.

The technology is particularly suited to creating whole muscle cut alternatives, which, for Scionti, is the direction the alternative meat industry is headed.

“Existing plant-based pork meats, such as Omnipork's products, are meant to be an alternative to ground pork meat,” explained the start-up’s founder. Green Monday-owned Omnipork, which first launched in Hong Kong in 2018, is a ground beef alternative made from pea, soy, shitake mushroom and rice.

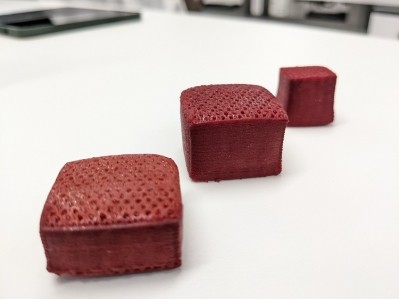

“On the other hand, we are mimicking the fibrous texture of pork whole-muscle cuts, which is a different level of complexity and is still not available yet on the market,” Scionti continued. “I believe that the alternative meat industry is moving beyond ground meat analogues.”

Pork skewer 2.0 is made from pea isolate, rice isolate, extra virgin olive oil, brown seaweed extract, beet juice concentrate and natural aroma.

Novameat is currently testing alternative ingredients, in proteins, fibres and oils, to ‘tune the flavourings’ and improve the product’s sustainability profile.

“Demonstrating that our technology works with a variety of ingredients is aimed at supporting biodiversity, to fight unsustainable monocultures and deforestation practices,” the CEO explained.

“Our goal is to demonstrate that our technology works at small- and later at large-scale, so that manufacturers using this technology will be able to select a variety of ingredients, to provide a wide array of tools to mimic different types of meat and seafood.”

First beef, now pork

Novameat started its meat alternative journey with what it claims to be the world’s first 3D-printed plant-based beef steak.

Its most recent version of the steak alternative (2.0) simultaneously exhibits the texture and appearance of a beef whole muscle cut, according to Scionti.

When asked how the beef and pork alternatives differ, he explained that their meat counterparts possess several differences in terms of structural, nutritional, and sensorial properties. Therefore, so do Novameat’s plant-based copies.

“For example, the content and distribution of intramuscular fat in beef and pork meats play a role in their appearance, texture and flavour differences.

“Compared to our plant-based steak, our newly released pork meat alternative has a different fat distribution within the micro-structured fibrous network. We use a scientific approach that includes a deep study of the muscle cuts we wish to mimic.”

Moving forward amid coronavirus outbreak

Moving forward, Novameat will be targeting food manufacturers, as well as the restaurant sector.

“I initially founded Novameat in November 2018 to leave a real impact on how we manage our planet's limited resources. For this reason, we are going to provide our technology at scale to food manufacturers that aim to increase their presence on the exponentially-growing plant-based meat market. This will allow us to really contribute towards a more sustainable and healthier food supply system.” – Novameat founder and CEO and Giuseppe Scionti

The start-up has already teed up chefs in Spain to test its beef and pork whole muscle cut prototypes, which will not only allow them to ‘master’ the technology, but help improve the final products.

“I'd like to see our realistic plant-based beef and pork meats in selected top restaurants by the end of 2020, before we will demonstrate our technology at industrial scale during 2021,” the founder revealed.

The company is also planning a new investment round for Novameat in autumn 2020.

Concerning the coronavirus outbreak, Scionti said the start-up’s activities have been ‘influenced substantially’ – mostly because his team has not had access to Novameat’s laboratory since mid-March.

However, the company has developed a new process of creation and development, separating engineering activities into the homes of engineering team members.

“For example, our senior food engineer Joan Solomando has brought some of our 3D printers to his home, and has designed and generated (all in one week!) our newly released plant-based pork meat prototype completely in remote, without the need to go to Novameat's lab,” Scionti told this publication.

“Keeping constant communication allowed us to adapt very quickly to the changes and develop a completely new (and spectacular) product in the middle of the pandemic. Also, 3D printing doesn't need big and complex equipment, and allows to keep the cost of production very low for prototyping activities.”