Faster concentration of foodborne pathogens on the horizon

The machine, which concentrates pathogens by using hollow thread-like fibers that filter out the cells, paves the way for traditional detection methods such as polymerase chain reaction (PCR), mass spectrometry and ELISA assays.

It enables researchers to carry out the concentration step within one hour, compared to a day for standard methods in commercial use.

The first step in detecting foodborne pathogens is concentrating the number of cells in test samples.

The continuous cell concentration device could make it possible to analyze food or water samples to screen for pathogens during food processing or vegetable washing before products are shipped.

It works by breaking down the sample into the consistency of a milkshake and chemically pretreated to prevent the filtering membranes from clogging.

The fluid is then passed through 12 hollow-fiber filters about 300 microns in diameter that are contained in a tube and the filtering process continues until any present pathogens are concentrated enough to be detected.

Cutting down time

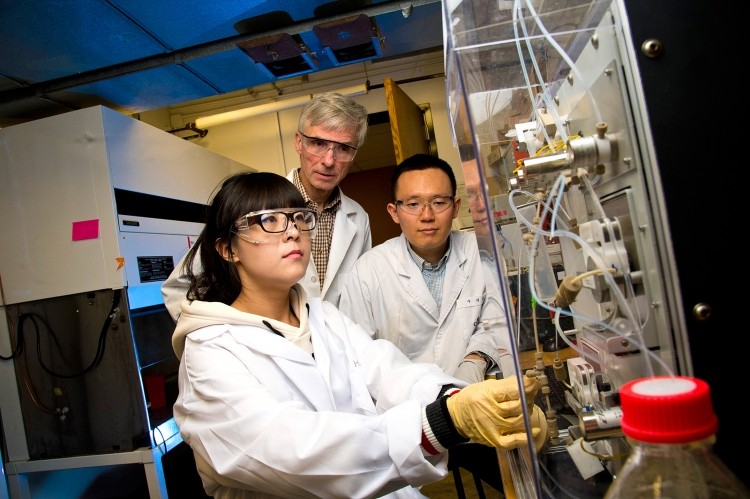

Michael Ladisch, a professor of agricultural and biological engineering at Purdue University, told FoodQualityNews.com that it would cut down the time between the sample being taken and the results coming back to determine if there is a problem.

“It concentrates all the organisms that are present, not all of them will be pathogenic.

“The sequence is sampling, pre-processing, concentrating the cells, recovery, detection and reporting in six hours or less. If there is a problem industry can intervene, it is another tool in their arsenal, as the sample can be taken and food cleared for shipment if it is ok or held back if not.”

Ladisch said the approach addresses the need for detecting food pathogens within six hours or in one work shift.

Initial research started in 2000 and was focussed around food pathogen detection and rapid methods for analysis.

Salmonella had been principally tested but the device is applicable to Listeria and E.coli.

Findings showed the system was able to concentrate inoculated Salmonella by 500 to 1,000 times the original concentration in test samples.

Room for improvement

It can recover 70% of the living pathogen cells in some samples but in others only 30% can be recovered, which is a problem they are working on, particularly some of the cells are still there and concentrated but not living anymore, said Ladisch.

“We wish to commercialise the system and make it publically available, so we will work here at Purdue with companies that are interested in scaling it up for applications such as veg washing.”

It is being tested by the US Department of Agriculture and Purdue has filed a patent application for the concept.

“We shipped the latest version about two months ago so testing is beginning, the aim is to reproduce the work we have done in the lab. The test is if others can do the same work independent from us and get the same result.

“We have to prevent this at the end of the day but the detection part is to make sure it is ok if prevention doesn’t work, so detection is an important metric.”

Source: Applied and Environmental Microbiology

Online, ahead of print: doi:10.1128/AEM.02587-13

“Rapid Sample Processing for Detection of Food-Borne Pathogens via Cross-Flow Microfiltration”

Authors: Xuan Li, Eduardo Ximenes, Mary Anne Roshni Amalaradjou, Hunter B. Vibbert, Kirk Foster, Jim Jones, Xingya Liu, Arun K. Bhunia, Michael R. Ladisch